Inflation-free-wheel energy conversion system

An energy conversion system and air-free technology, which is applied to electrical components, vehicle components, and mechanical energy control, can solve problems such as waste and conversion, and achieve a high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

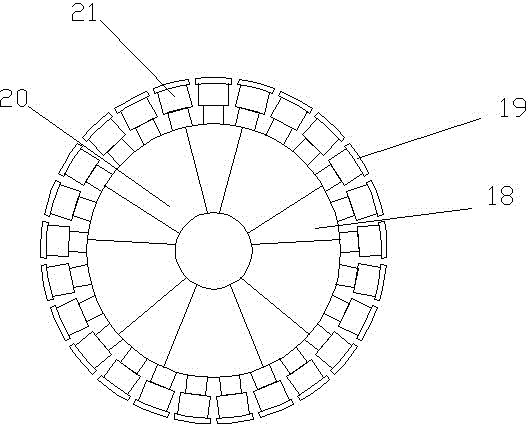

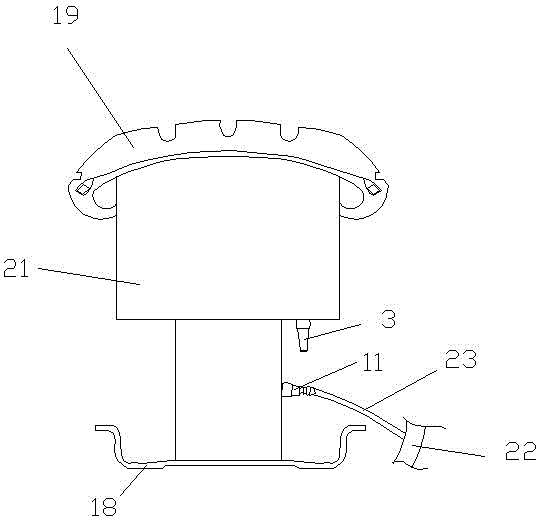

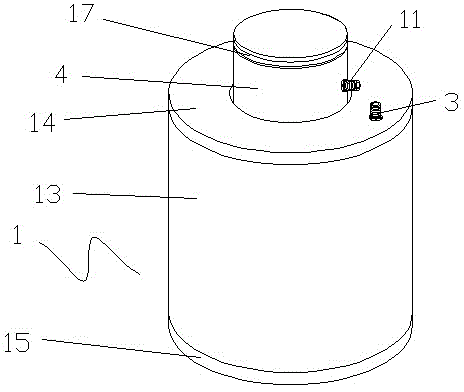

[0031] A kind of air-free wheel energy conversion system described in this embodiment 1, such as figure 1 , figure 2 As shown, it includes the wheel used in conjunction with the main frame of the car. The wheel is composed of a rim 18 mounted and connected to the axle, and spokes 20 provided on the rim. The annular surface of the rim facing the ground is provided with a reciprocating compression power device. The compression power device is a compressed air pump 21, and a plurality of compressed air pumps are arranged in a circular distribution along the annular surface of the rim, and each compressed air pump is independently provided with a tire rubber 19 on the end surface in contact with the bottom surface; each compressed air pump is provided with There is a return spring capable of resetting; each compressed air pump is connected to a generator located on the wheel rim or the main frame of the car, and the compressed air generated by the compressed air pump is used to g...

Embodiment 2

[0039] This embodiment 2 is improved on the basis of embodiment 1, and the specific difference of this embodiment 2 is:

[0040] The generator is directly installed and hidden in the main frame of the automobile. The generator can also be hidden in the main frame of the car and integrated with the main frame of the car to solve the installation position and complexity of the wheels.

Embodiment 3

[0042] This embodiment 3 is also improved on the basis of embodiment 1, and the specific difference of this embodiment 3 is:

[0043] The generator is a screw expansion generator. The screw expansion generator can also be used for power generation. The working principle of the screw expansion generator can be roughly divided into:

[0044] 1. Air intake process: After the compressed air enters the inter-tooth volume of the rotor through the air inlet of the screw expansion generator, it will drive the rotor to rotate and make the inter-tooth volume continuously expand. When the inter-tooth volume is completely equal to the progress of the screw expansion generator When the air port is disengaged, the air intake process ends;

[0045] 2. Expansion process: As the volume between the teeth continues to increase, the volume expansion temperature of the compressed gas decreases, and at the same time, the power is output to the extended shaft of the rotor;

[0046] 3. Exhaust proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com