Novel folding and cutting machine

A cutting machine and a new type of technology, applied in the field of textile machinery and equipment, can solve the problems of reduced production efficiency, large occupied area and high manufacturing cost, and achieve the effects of improving stability, speed and effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

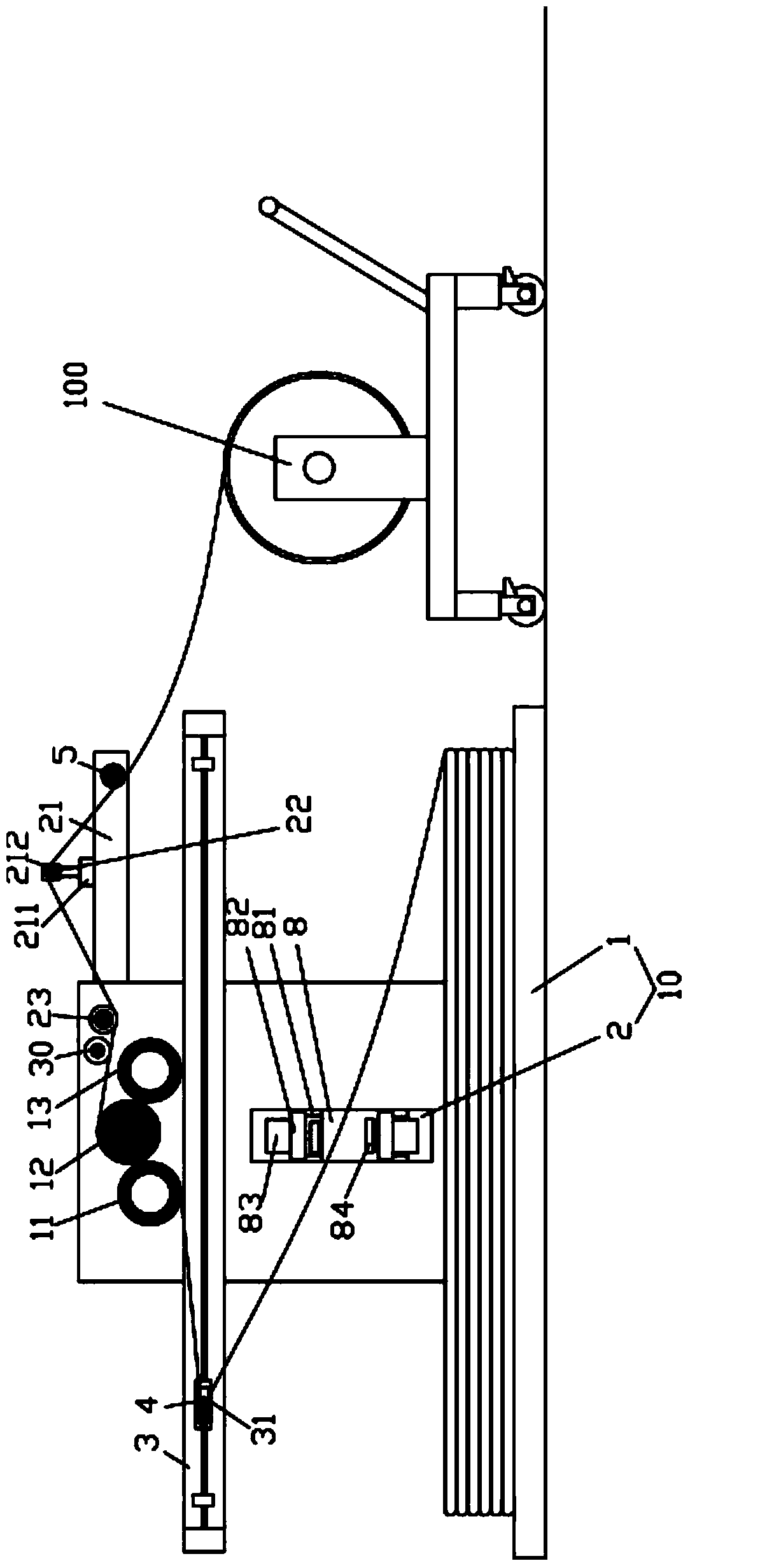

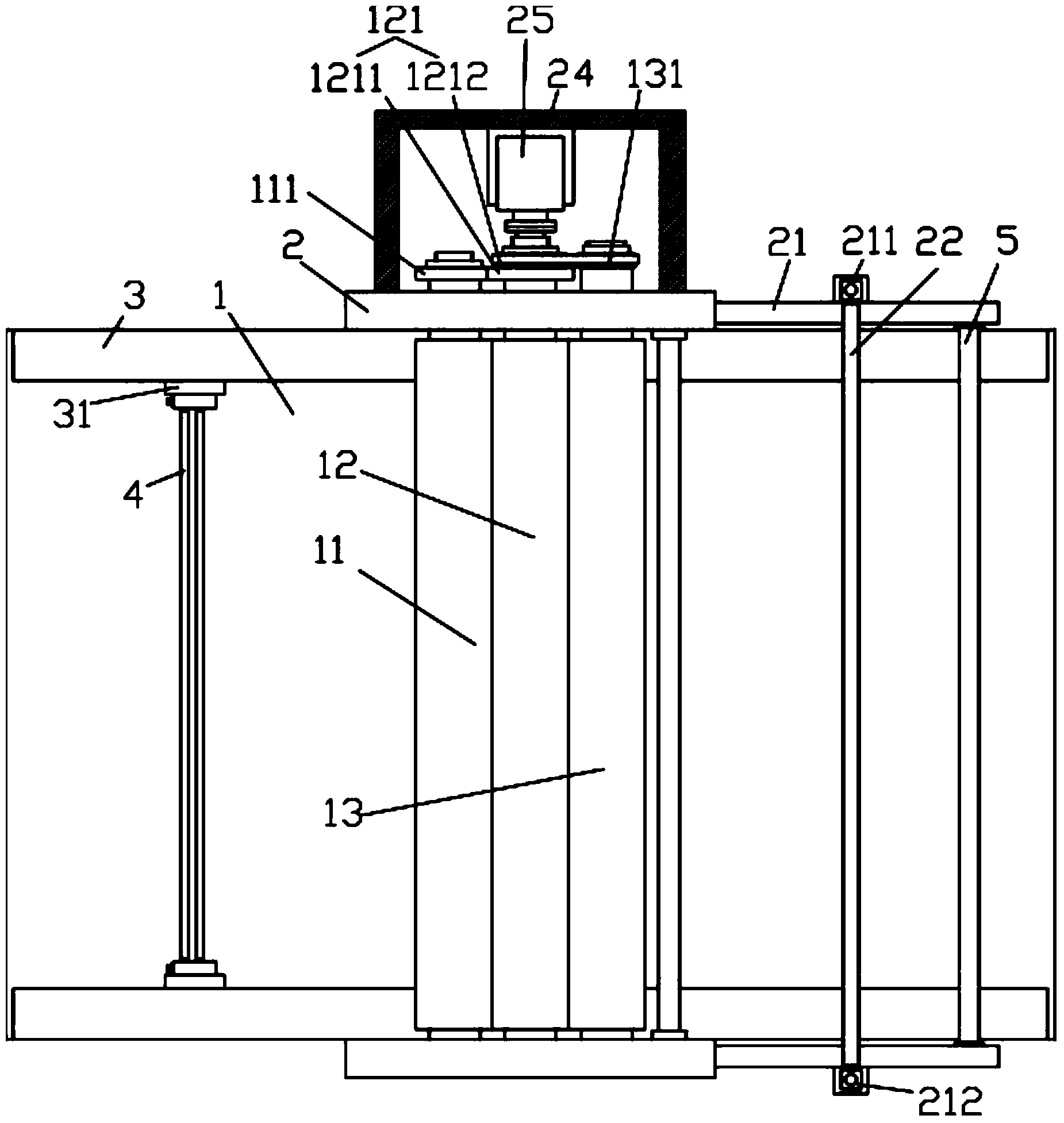

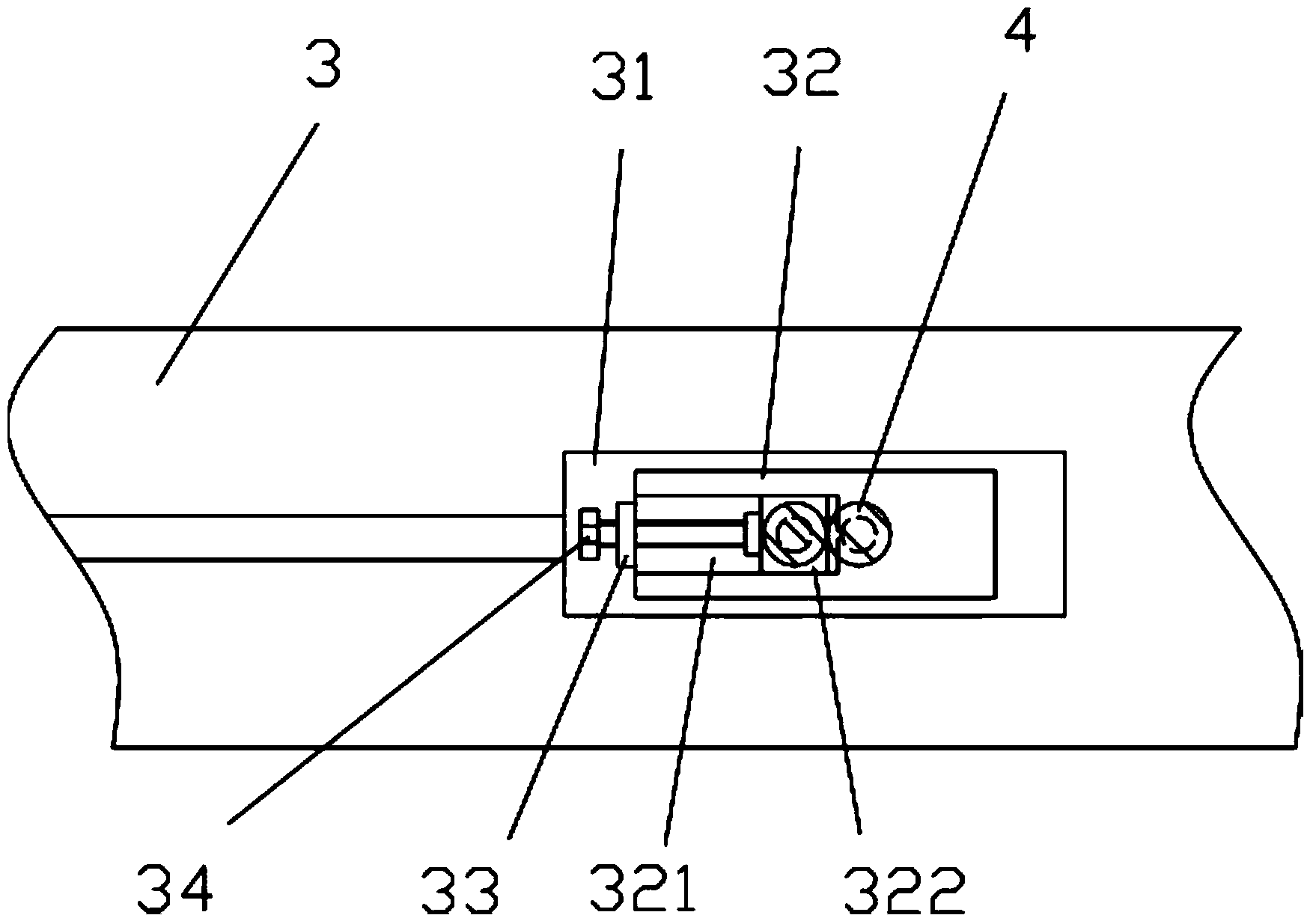

[0026] Examples, see Figure 1 to Figure 8 As shown, a new type of folding and cutting machine includes a frame 10, and the frame 10 includes a cloth laying board 1 at the bottom and vertical support boards 2 fixed on both sides of the cloth laying board 1, two vertical The inner side wall of the straight support plate 2 is fixed with a horizontal rodless cylinder 3, and the two ends of the two folding rods 4 are respectively arranged on the slider 31 of the rodless cylinder 3, and the two folding rods 4 are close to each other;

[0027] The two ends of the first transmission roller 11, the second transmission roller 12 and the third transmission roller 13 are respectively hinged on the top of two vertical support plates 2, and the second transmission roller 12 is connected between the first transmission roller 11 and the third transmission roller 13. between;

[0028] The right side of the top of the inner side wall of two vertical support plates 2 is hinged with middle supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com