Back-carried type wire barrow

A pay-off car and knapsack technology, applied in the field of pay-off car, can solve the problems of being unsuitable for long-term use and heavy carrying, and achieve the effects of light weight, reduced carrying weight, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

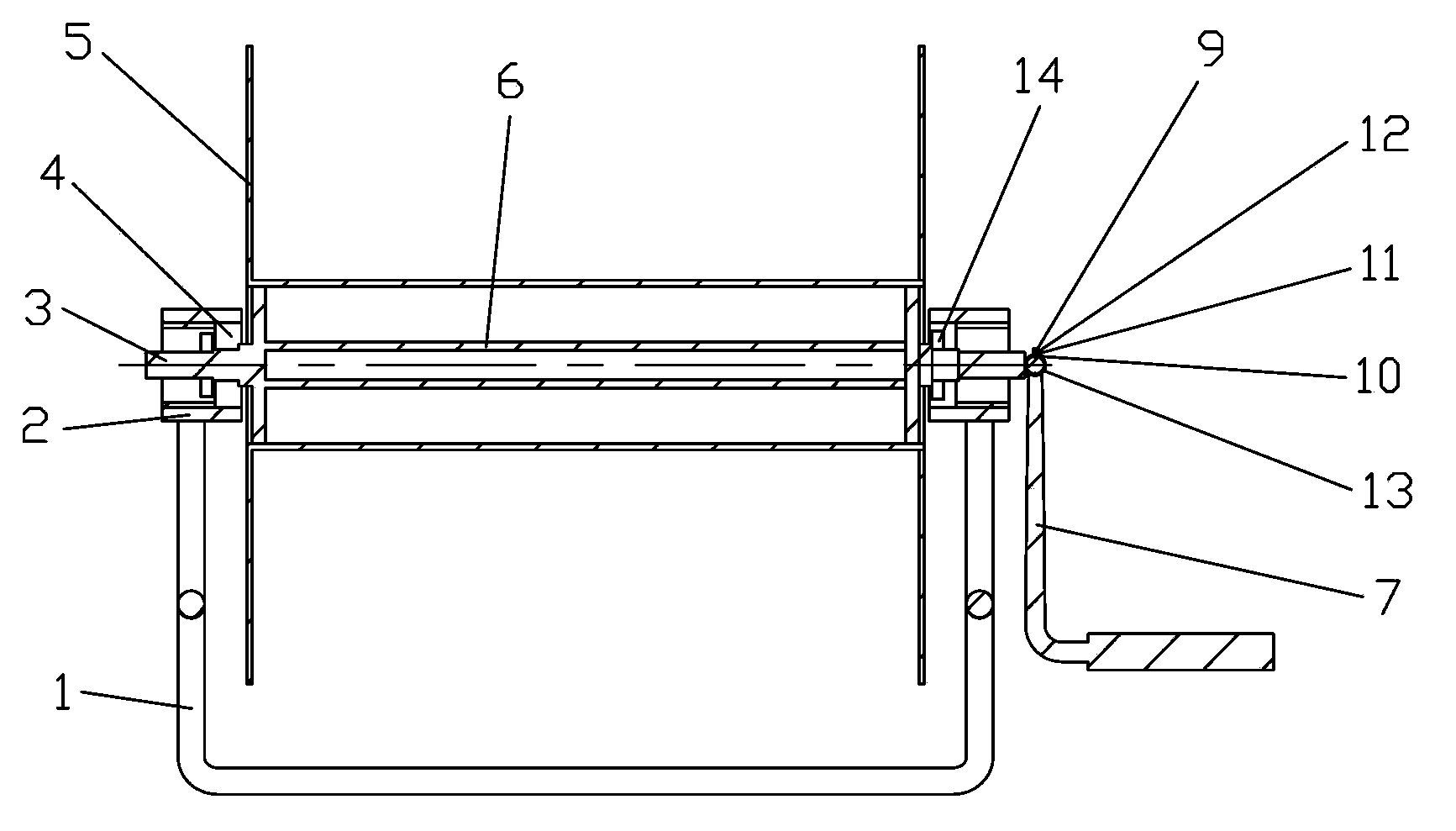

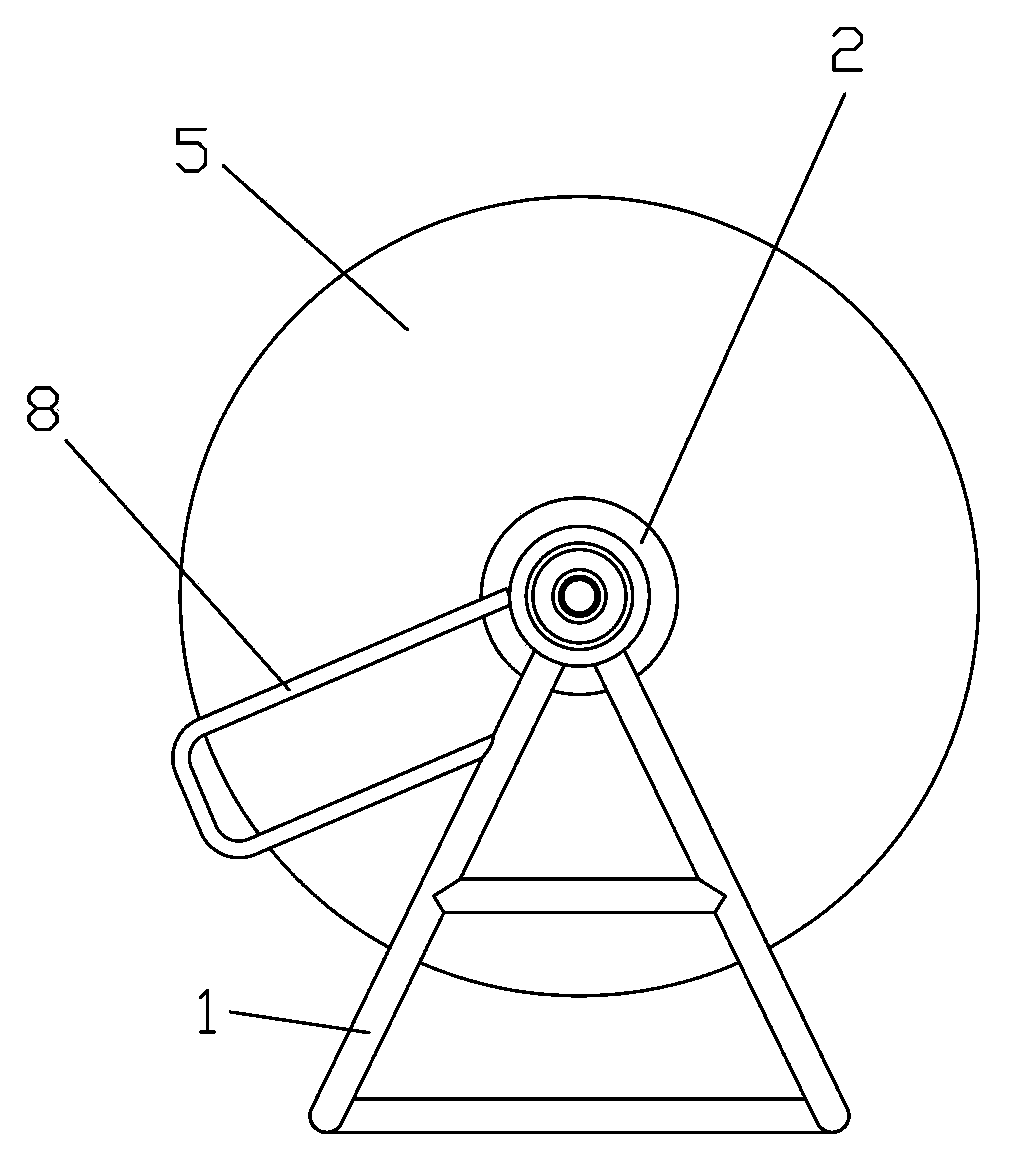

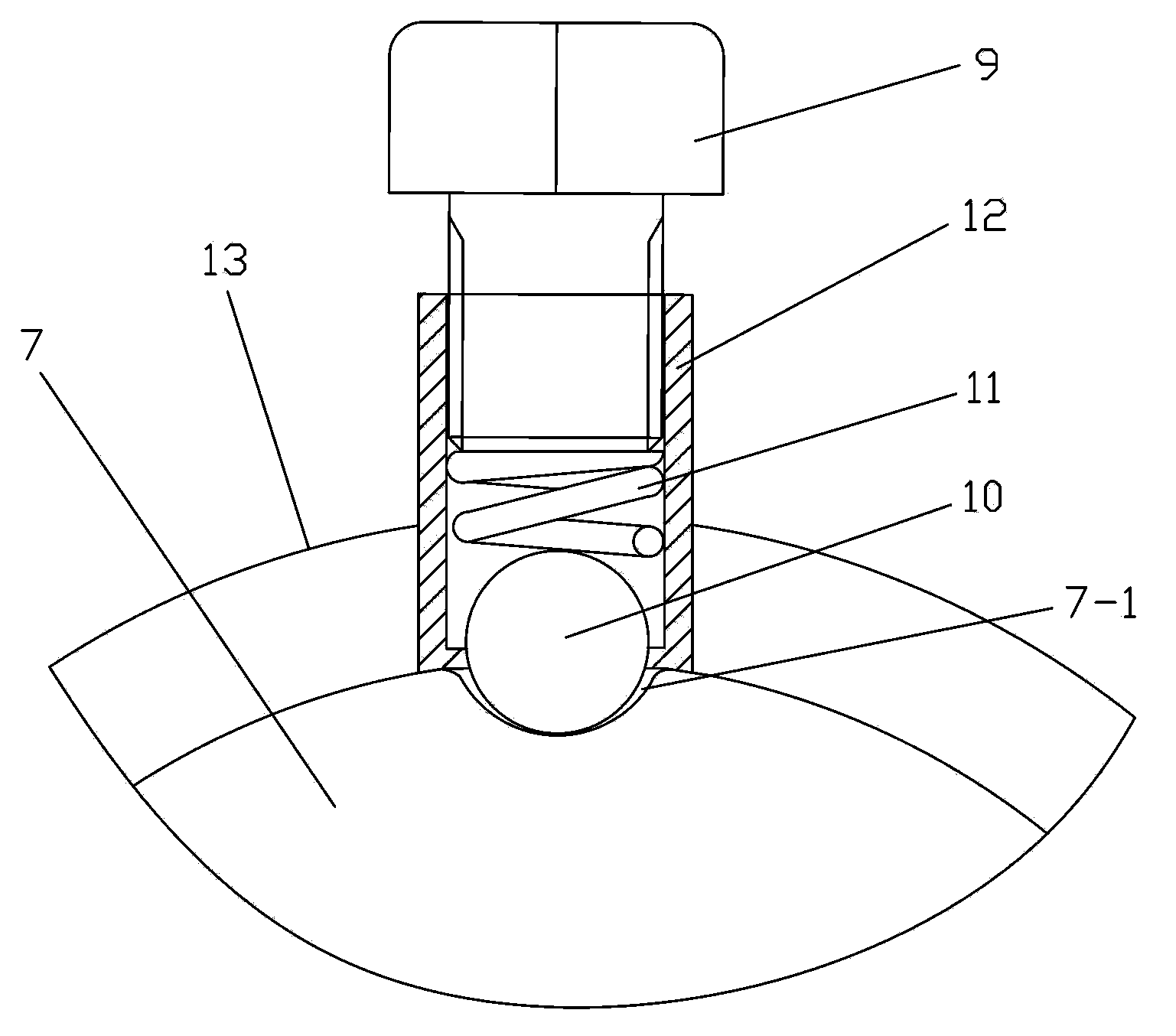

[0022] Such as figure 1 , figure 2 with Figure 4 As shown, the present invention includes a bracket 1, a bearing seat 2, a roller 3, a bearing 4, a winding roller 5, a connecting shaft 6 and a strap hanging ring 8, and is used to drive the roller 3 and the connecting shaft 6 to rotate together to realize the wire release With the handle rotation mechanism for taking up the wire, the support 1 is a triangular steel bar support, the number of the bearing seats 2 is two and the two bearing seats 2 are installed on the upper two ends of the support 1 respectively, and the number of the rollers 3 Two, the number of the bearing 4 is two, the roller 3 is installed on the bearing seat 2 through the bearing 4 and the end is locked by the nut 14, the connecting shaft 6 is a hollow tube, and the connecting shaft 6 The two ends of the two rollers 3 are welded respectively to form an integral rotating shaft. The winding roller 5 is a hollow plastic winding roller with a large plate at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com