Jacquard needle piece of warp knitting machine

A warp knitting machine and needle block technology, used in warp knitting, knitting, textiles and papermaking, etc., can solve the problems of weak insulation protection layer, leakage of piezoelectric ceramic sheets, fatigue failure, etc., to reduce production costs and improve Production efficiency, the effect of ensuring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

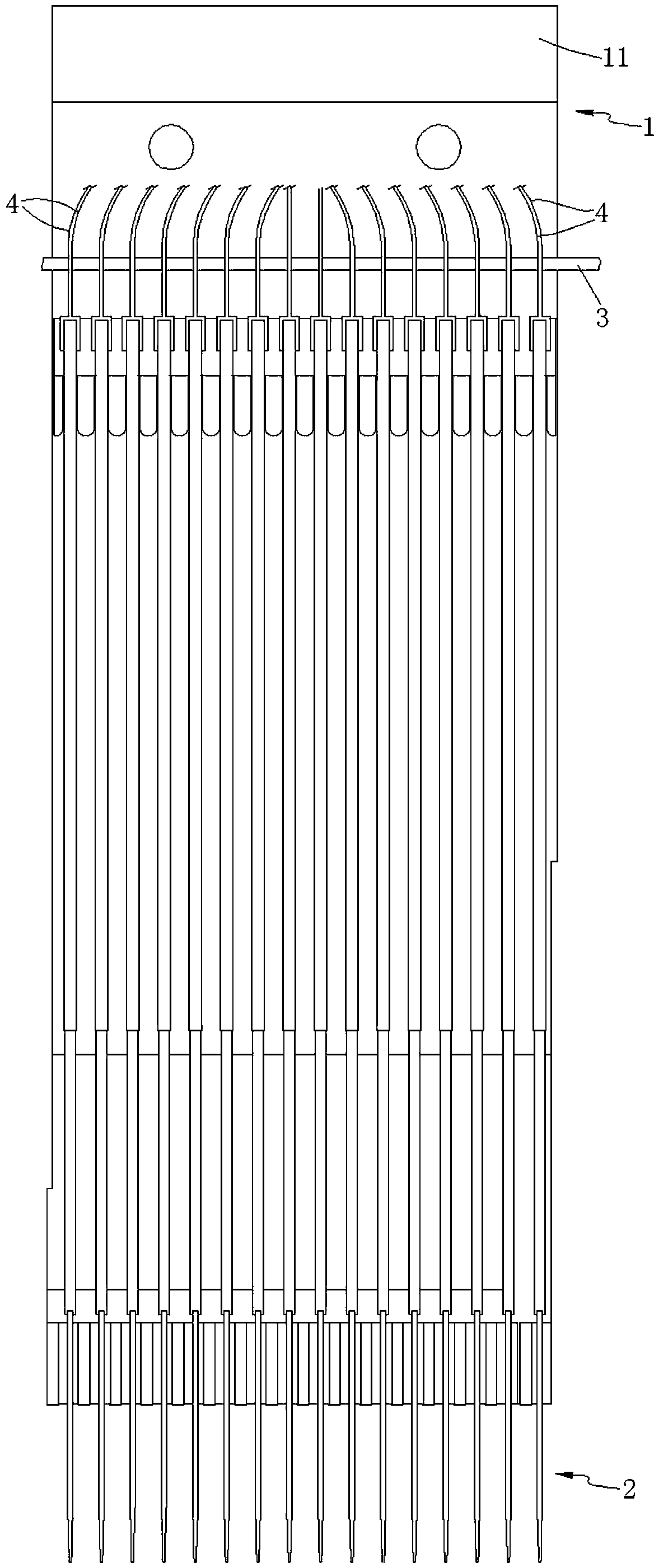

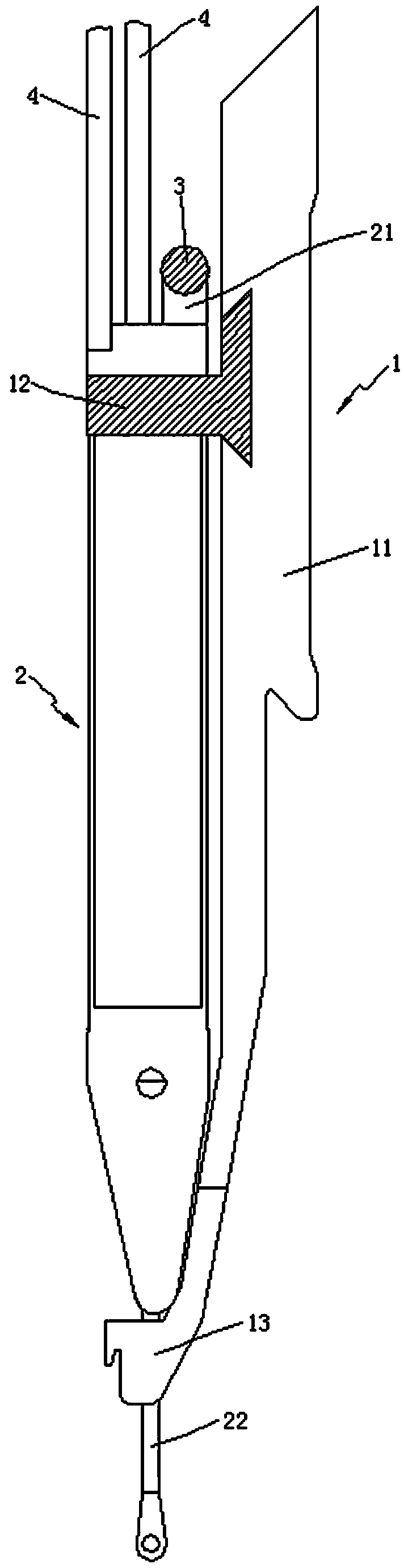

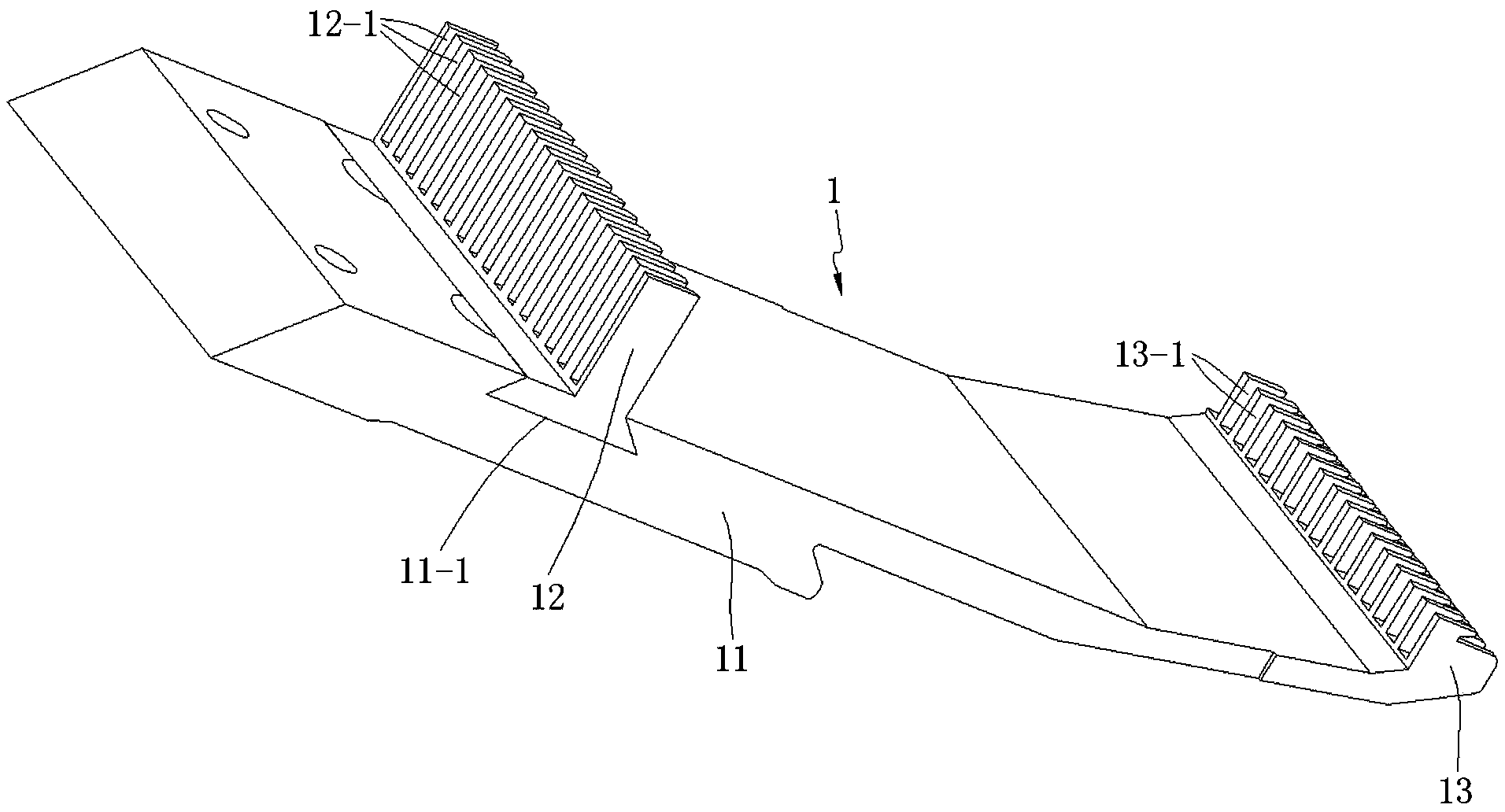

[0029] see Figure 1 to Figure 12 The jacquard needle block of a warp knitting machine shown includes a jacquard needle base 1 and several piezoelectric ceramic selectors 2; the jacquard needle base 1 has a base plate 11, a needle block 12 and a limit block 13 , the needle block 12 is provided with some needle insertion grooves 12-1 arranged in parallel at a certain distance from each other, and the limit block 13 is provided with some limit grooves 13-1 arranged in parallel at a certain distance from each other A piezoceramic selector piece 2 is embedded in each needle slot 12-1 of the needle block 12 and the corresponding limit groove 13-1 on the limit block 13; each piezoelectric ceramic selector Needle piece 2 comprises intermediate substrate 21, guide needle 22 and the piezoelectric ceramic sheet 23 that is arranged on the two sides of described intermediate substrate 21, and described yarn guide needle 22 passes through its upper needle piece and piezoelectric cerami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com