Patents

Literature

36results about How to "Avoid depolarization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

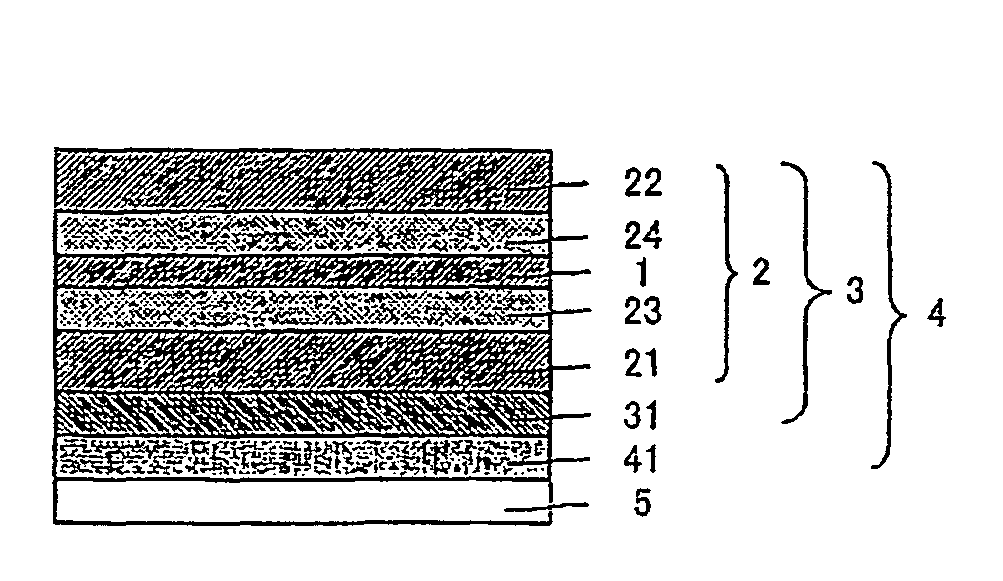

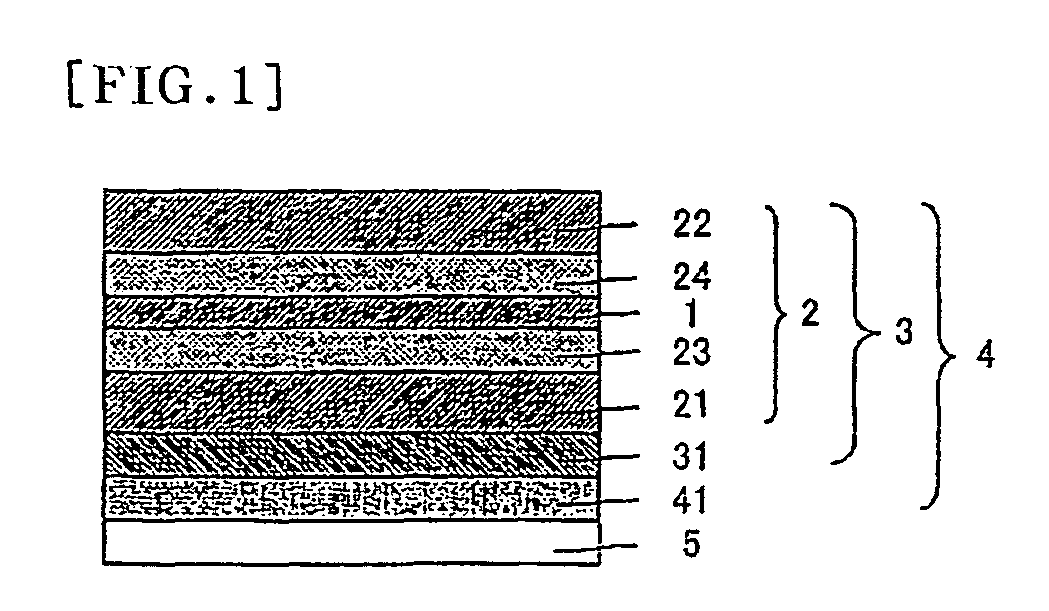

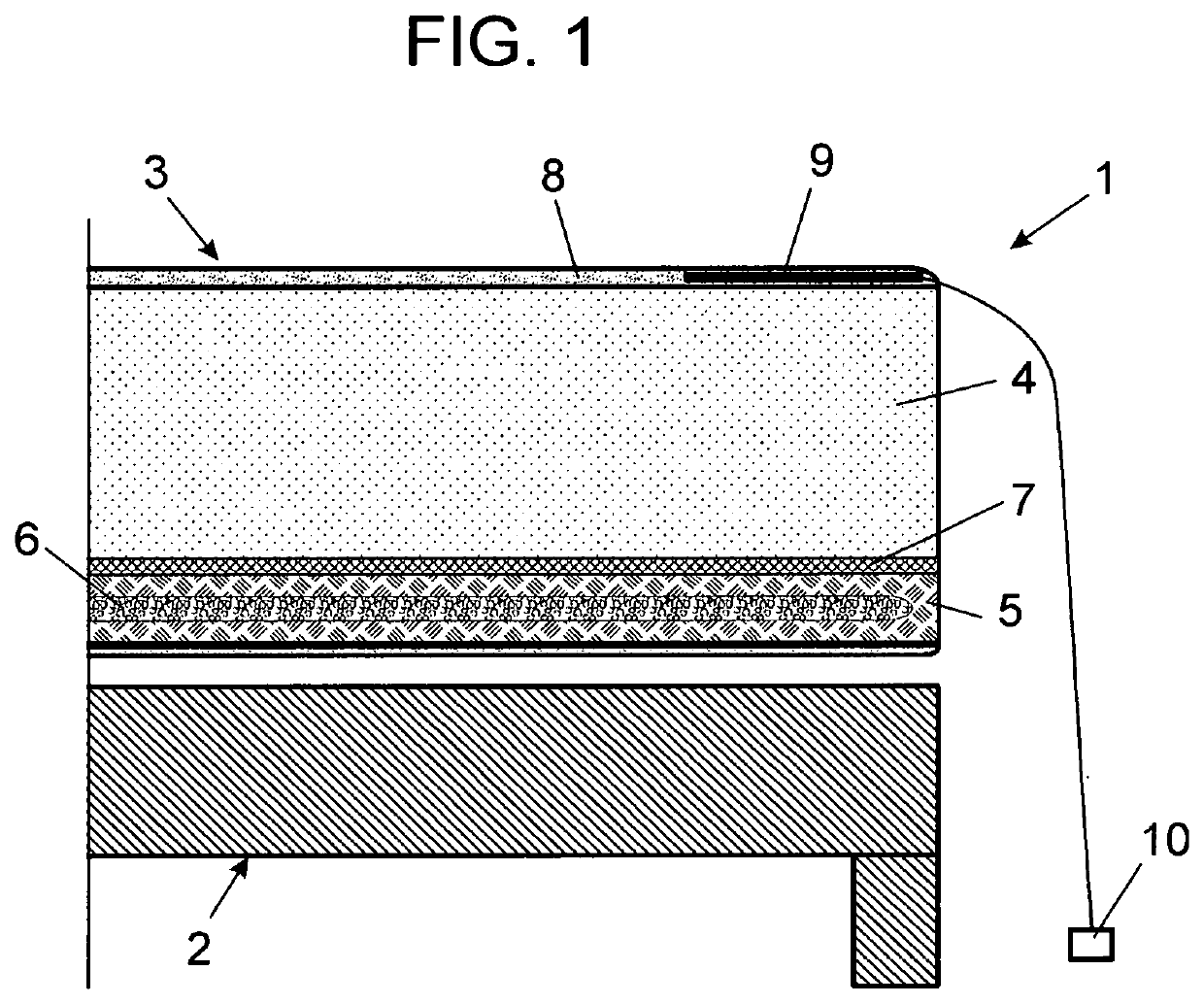

Pressure-sensitive adhesive and retardation layer-attached polarizing plate, method for manufacturing thereof, optical film, and image display

ActiveUS20100039590A1Improve visibilityVisibility can be maintainedLiquid crystal compositionsPolarising elementsTectorial membranePolyvinyl alcohol

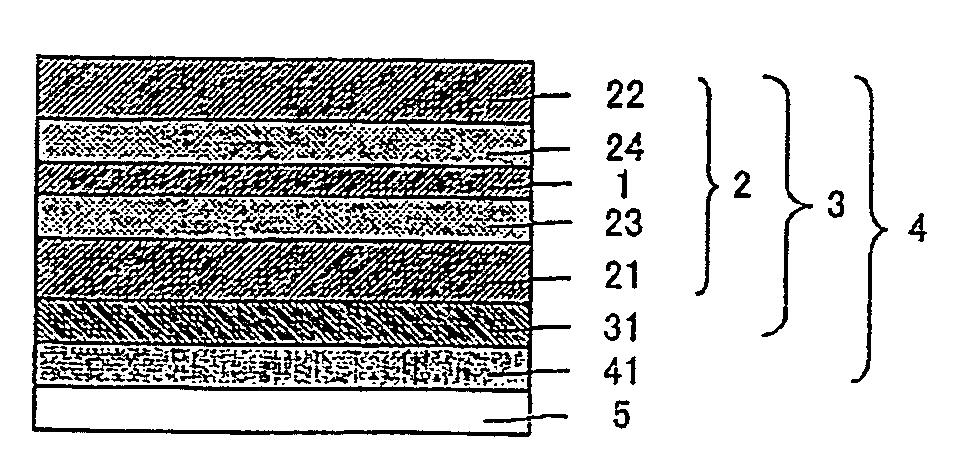

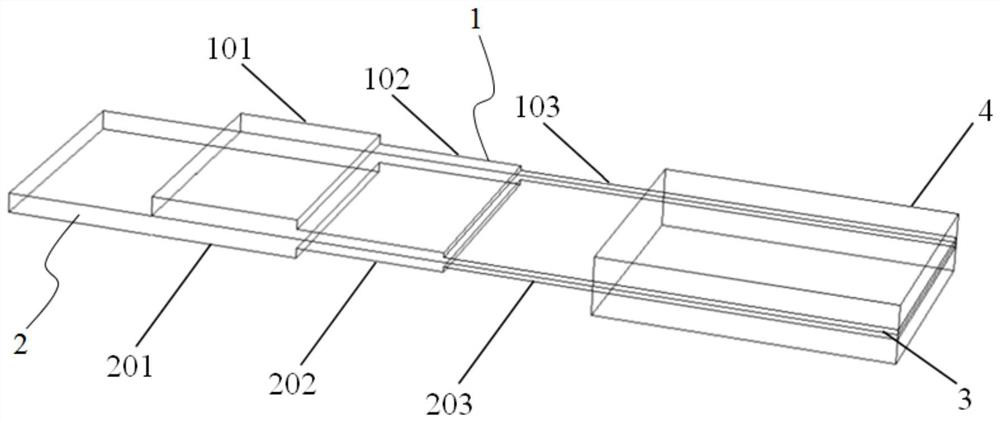

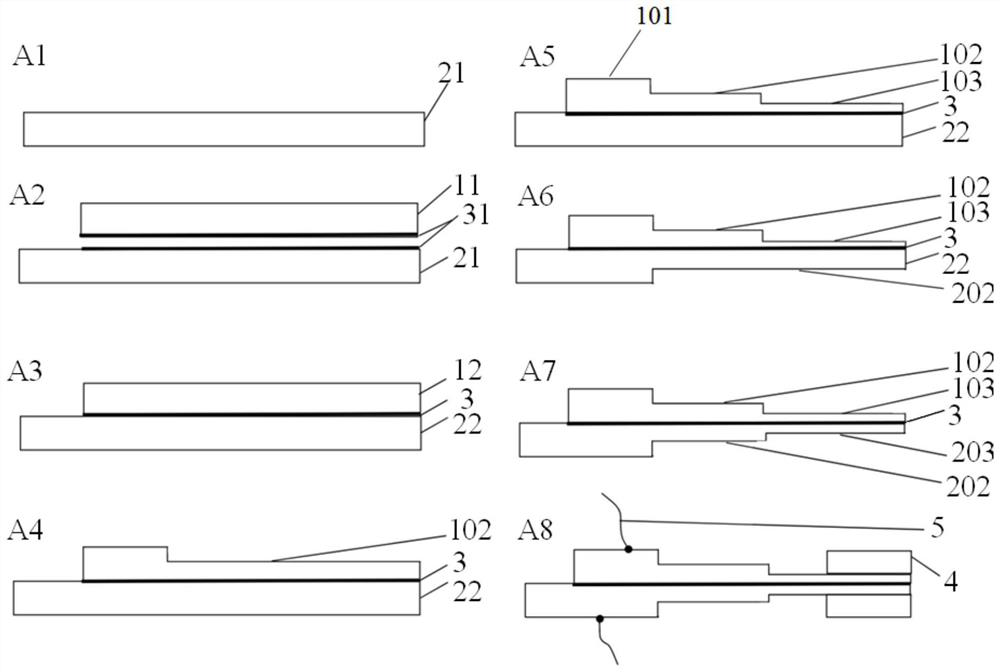

A pressure-sensitive adhesive and retardation layer-attached polarizing plate (4) of the invention comprises a retardation layer-attached polarizing plate (3) comprising a polarizing plate (2) that comprises an iodine-based polarizer (1) and a transparent protective film laminated on both sides of the polarizer (1); and a retardation layer provided on at least one of the transparent protective films; and an acrylic pressure-sensitive adhesive layer laminated on the retardation layer side of the retardation layer-attached polarizing plate (3), wherein the iodine-based polarizer (1) has a ratio (K / I), which is the content (% by weight) of potassium (K) to the content (% by weight) of iodine (I) in the polarizer, of 0.200 to 0.235, the polarizing plate (2) comprises the iodine-based polarizer (1) and the transparent protective film laminated with an adhesive layer formed from a water-soluble adhesive containing an acetoacetyl group-containing polyvinyl alcohol resin and a crosslinking agent, the retardation layer-attached polarizing plate (3) has a measured dimensional shrinkage of 0.5% or less in the direction of its absorption axis after it is allowed to stand at 80° C. for 24 hours, the pressure-sensitive adhesive and retardation layer-attached polarizing plate (4) has a single-piece transmittance of 41.0% to 43.2%. The pressure-sensitive adhesive and retardation layer-attached polarizing plate can resist a change in optical properties and keep visibility high, even under heated or humidified conditions.

Owner:NITTO DENKO CORP

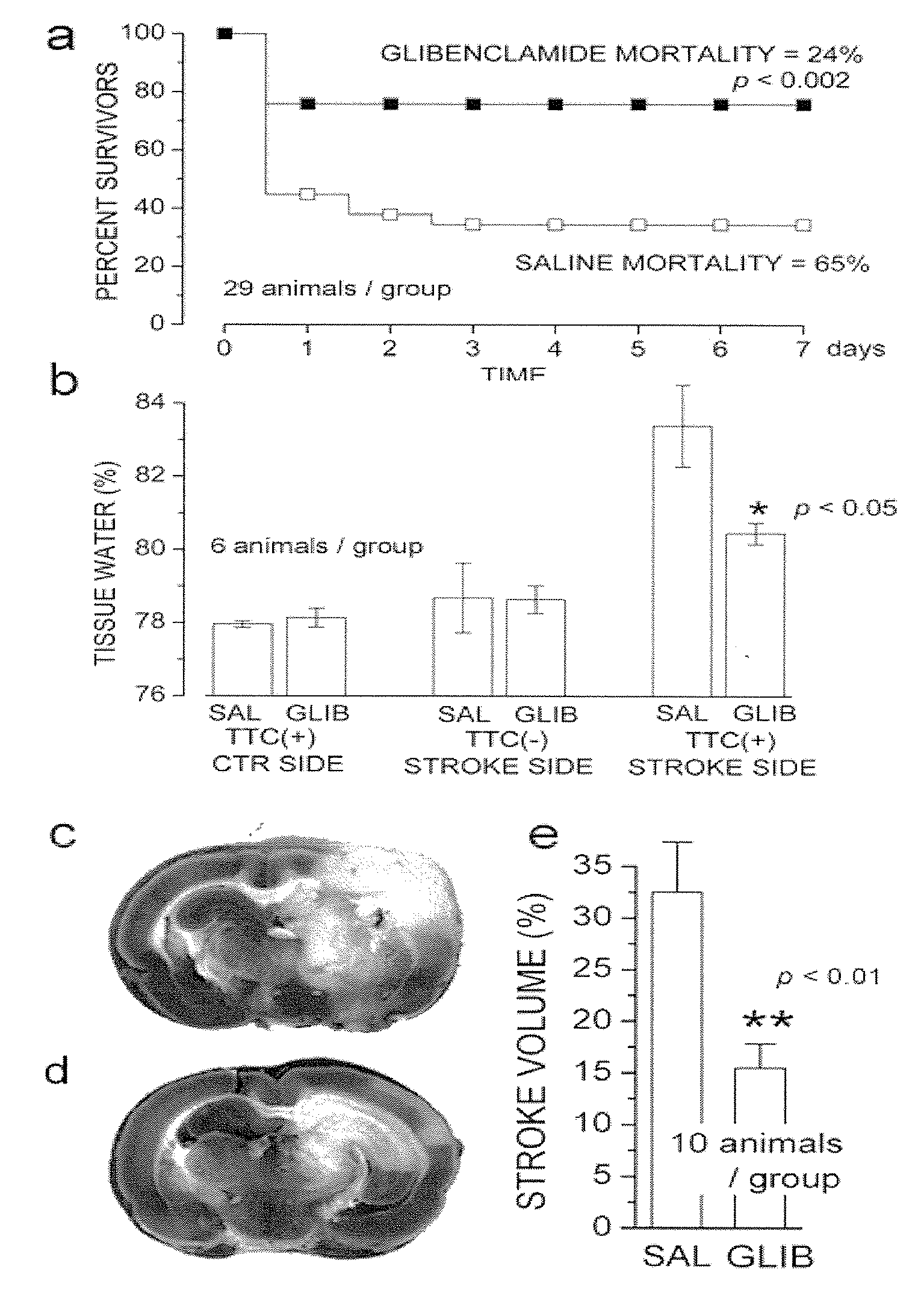

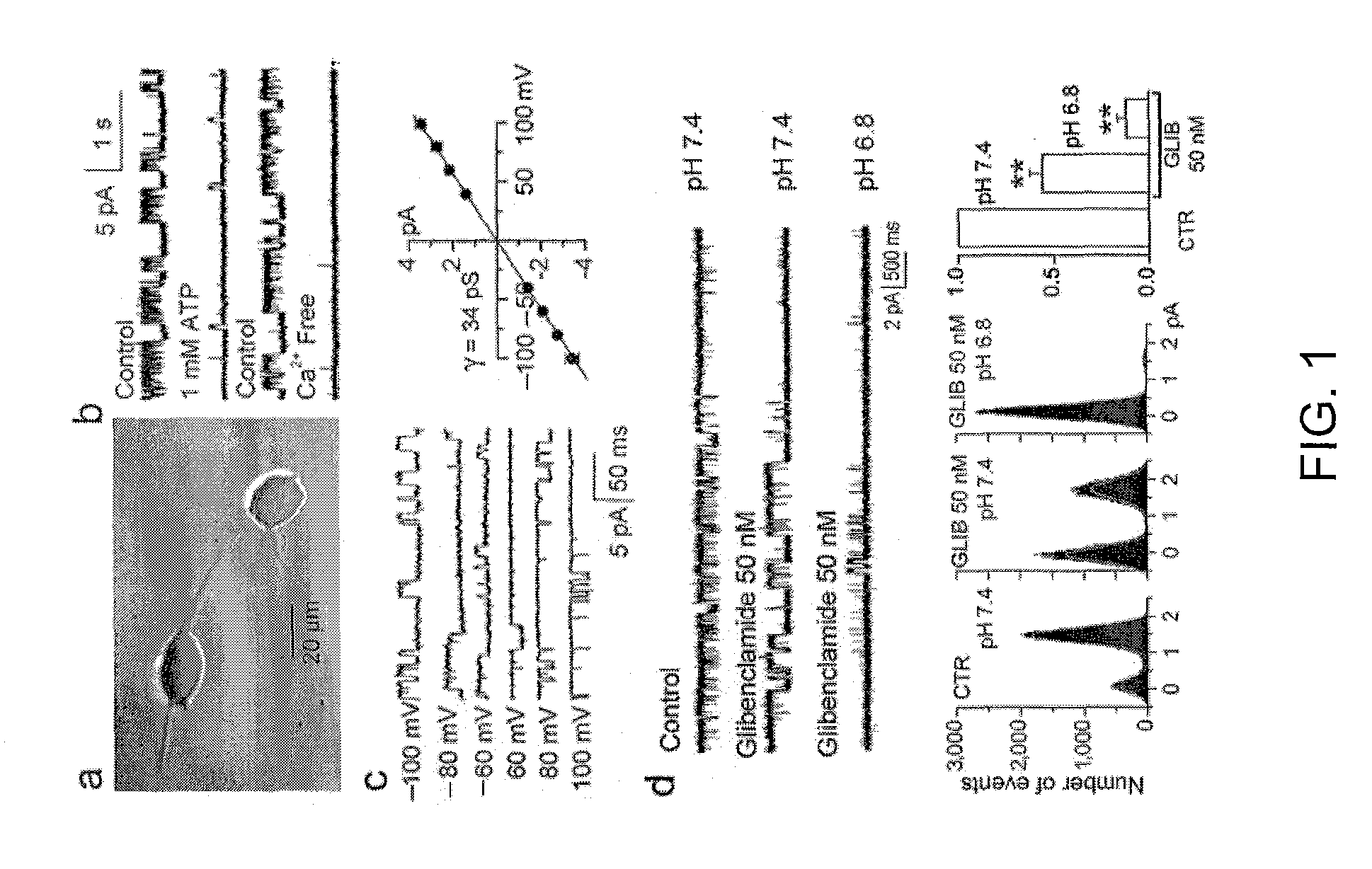

Antagonists of a non-selective cation channel in neural cells

InactiveUS20100092469A1Reduce mortalityReduces stroke sizeBiocideNervous disorderDiseaseNervous system

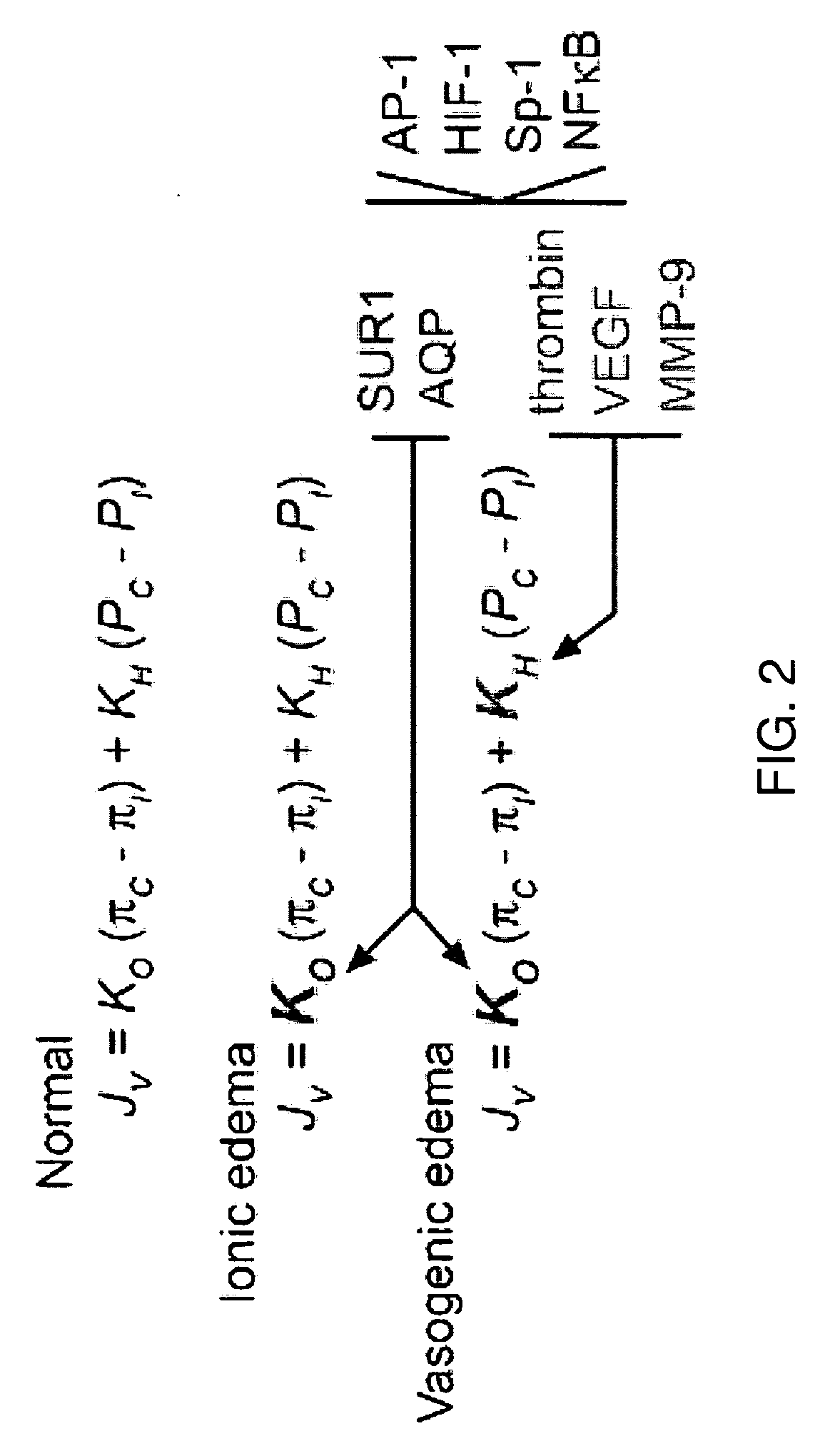

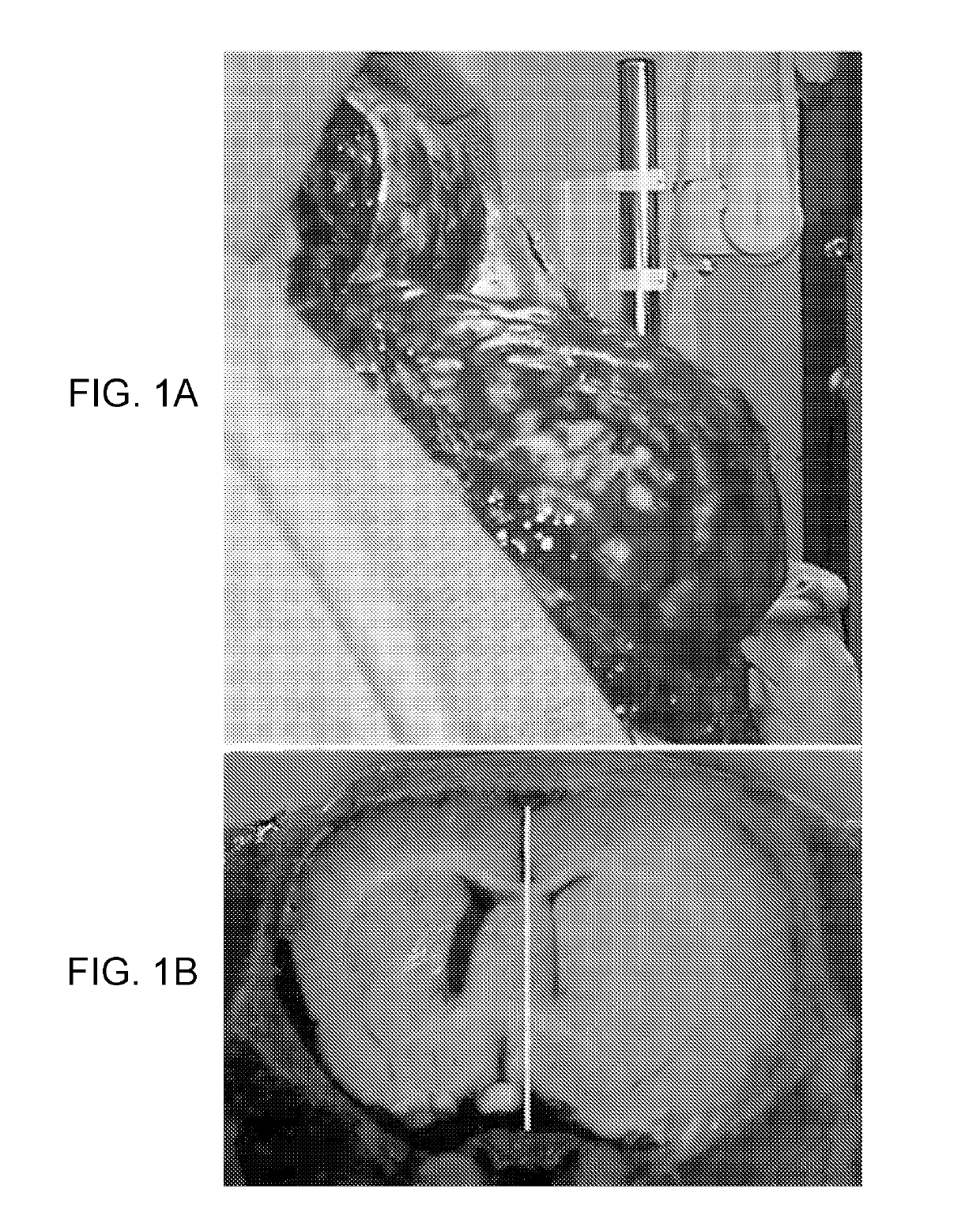

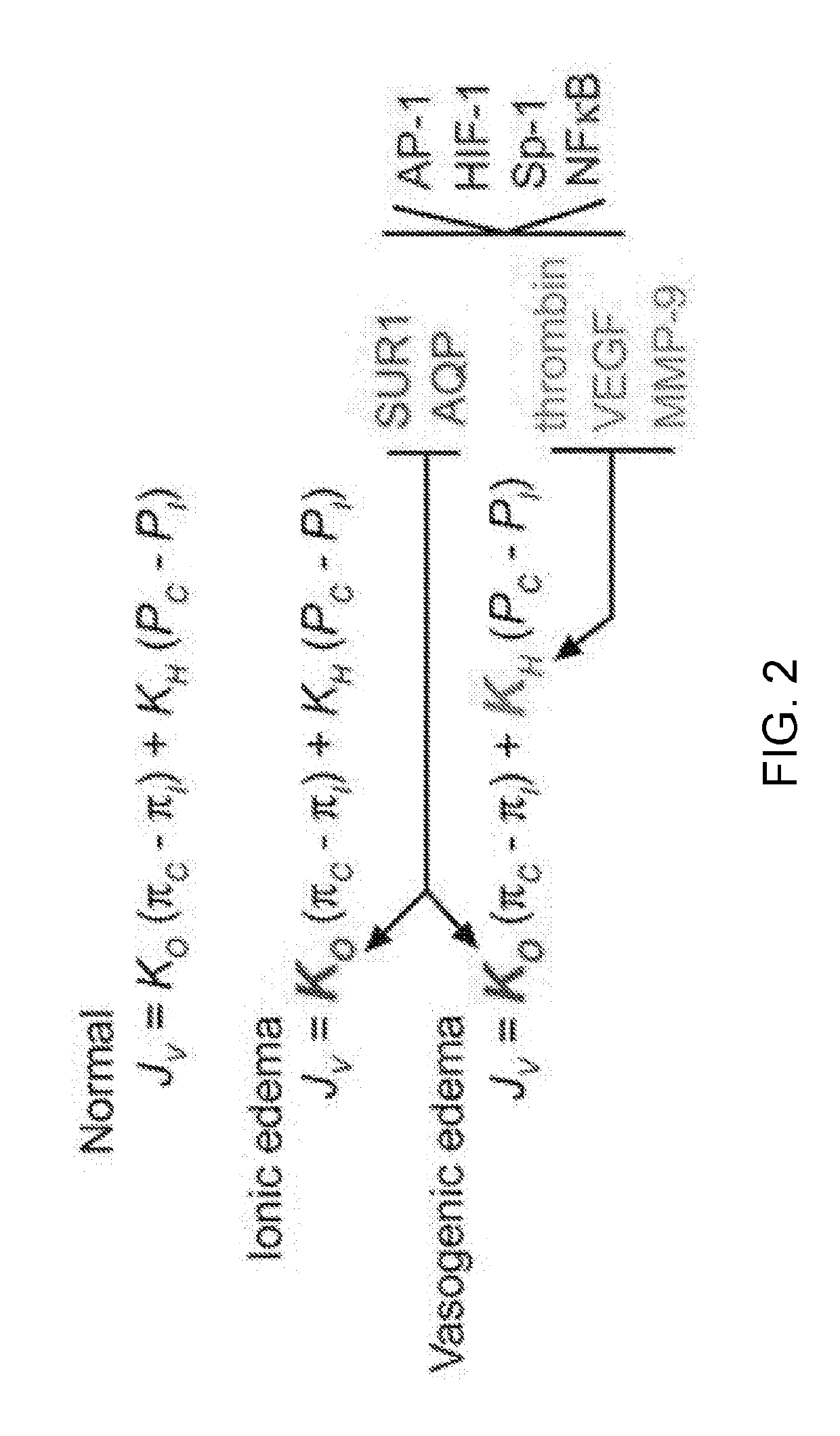

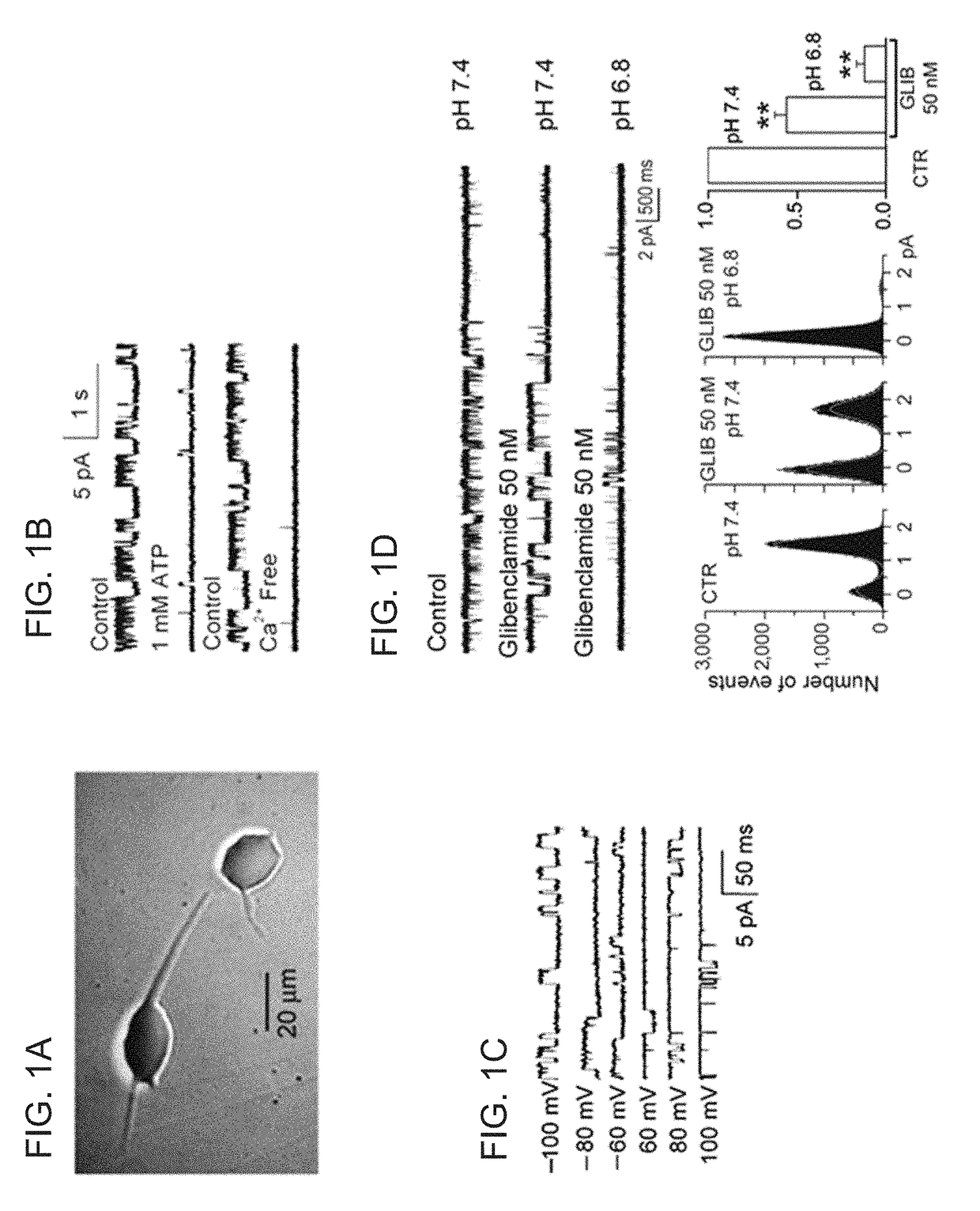

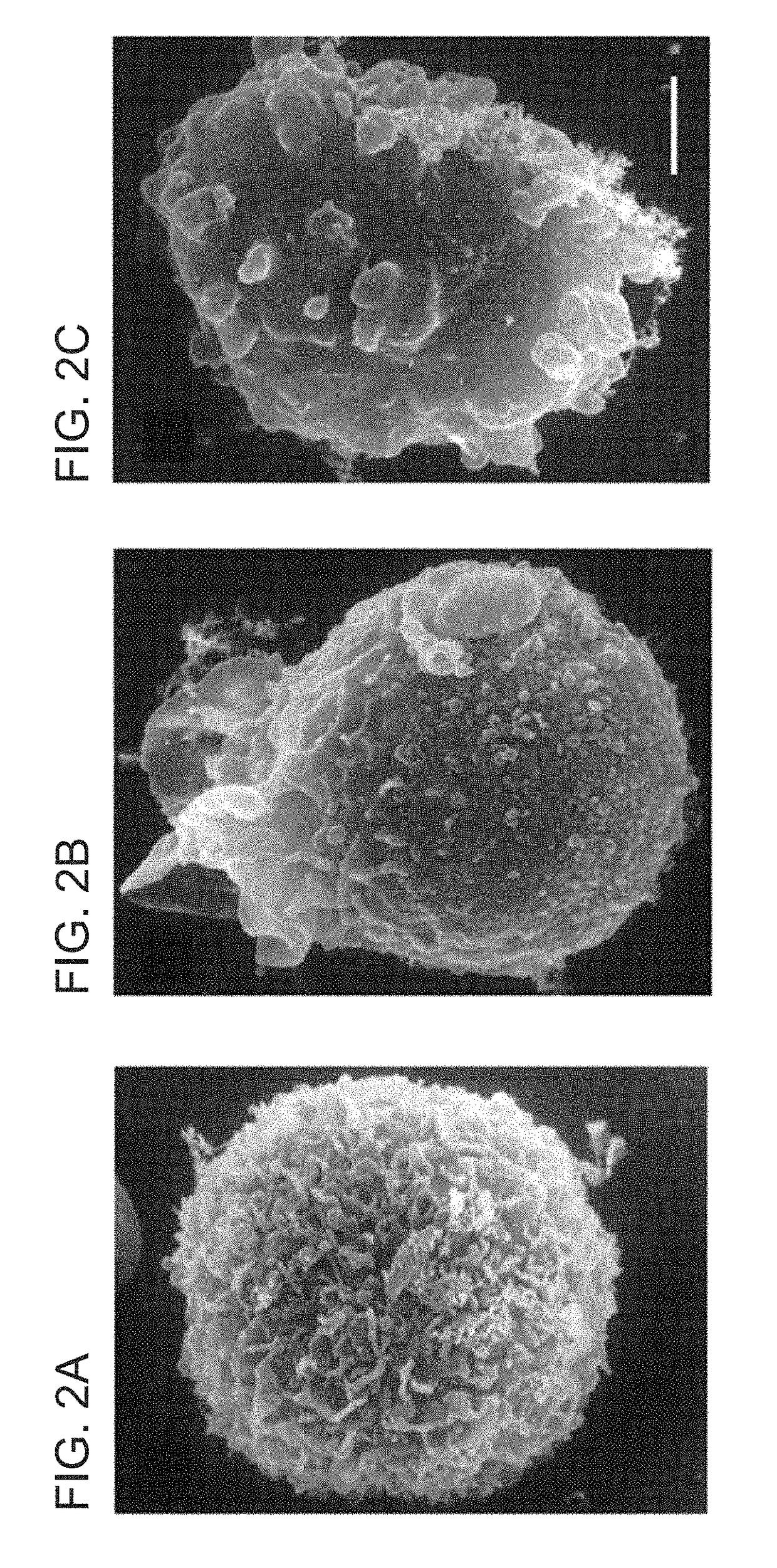

The present invention is directed to a combination of therapeutic compounds and treatment methods and kits using the combination. In particular, one of the combination affects the NCca-ATP channel of neural tissue, including neurons, glia and blood vessels within the nervous system. Exemplary SUR1 and / or TRPM4 antagonists that inhibit the NCca-ATP channel may be employed in the combination. The combination therapy also employs one or more of a non-selective cation channel blocker and / or an antagonist of VEFG, NOS, MMP, or thrombin. Exemplary indications for the combination therapy includes the prevention, diminution, and / or treatment of injured or diseased neural tissue, including astrocytes, neurons and capillary endothelial cells, that is due to ischemia, tissue trauma, brain swelling and increased tissue pressure, or other forms of brain or spinal cord disease or injury, for example. In other embodiments, there are methods and compositions directed to antagonists of TRPM4, including at least for therapeutic treatment of traumatic brain injury, cerebral ischemia, central nervous system (CNS) damage, peripheral nervous system (PNS) damage, cerebral hypoxia, or edema, for example.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE DEPT OF VETERANS AFFAIRS

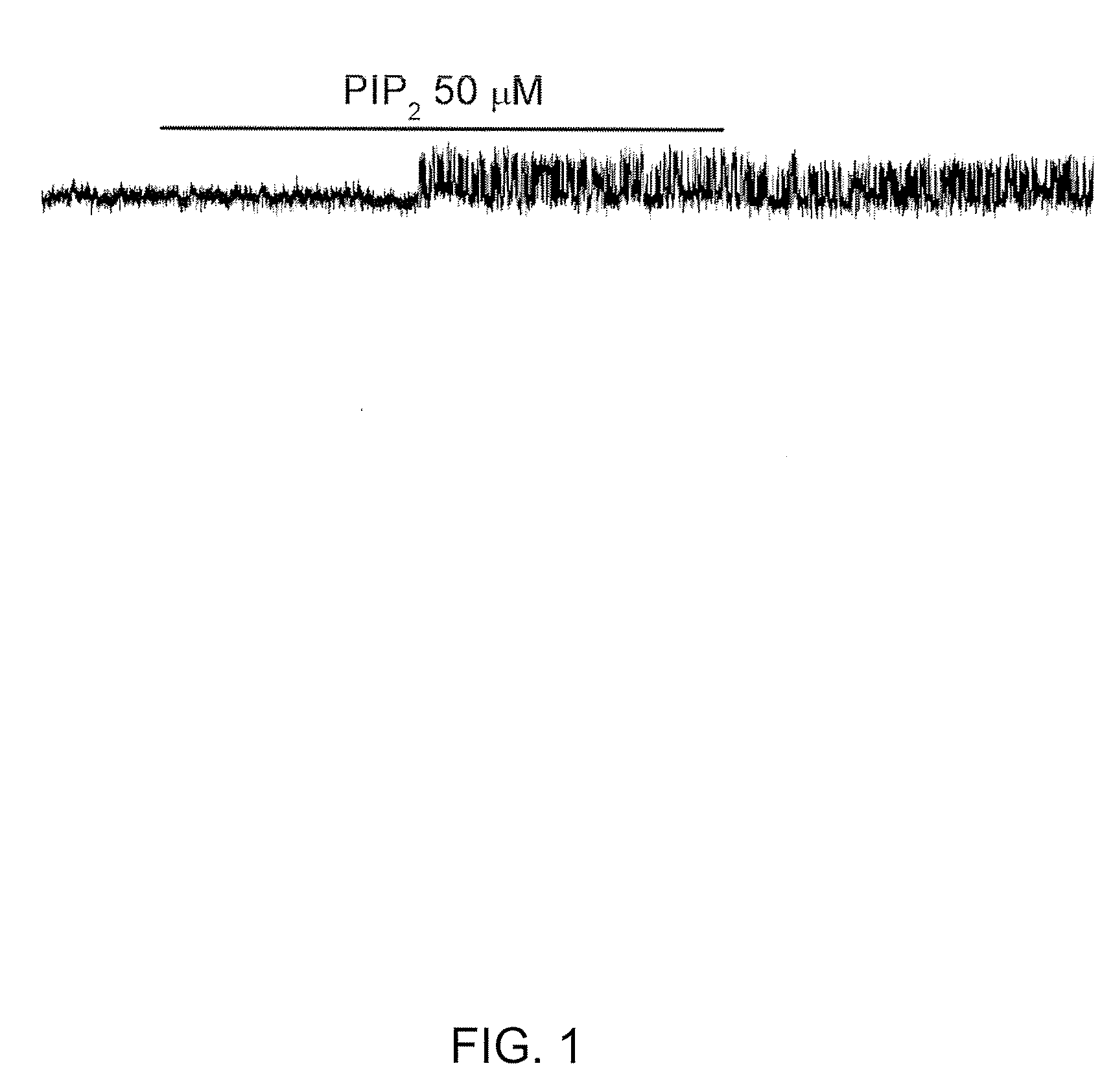

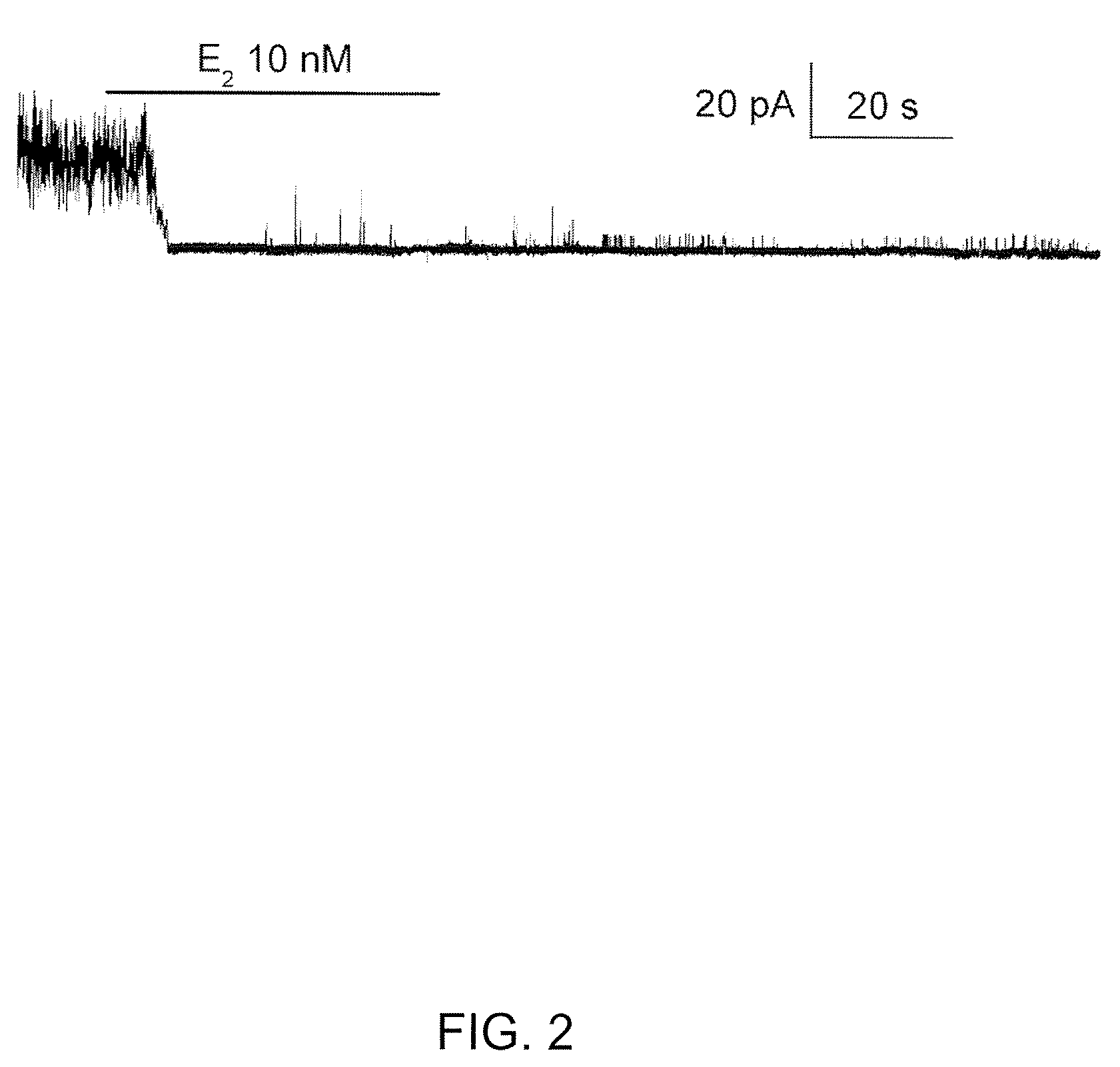

Therapeutic Agents Targeting the NCCA-ATP Channel and Methods of Use Thereof

ActiveUS20090130083A1Expanding Therapeutic WindowAvoid depolarizationBiocideNervous disorderAbnormal tissue growthAntagonist

The present invention is directed to therapeutic compositions targeting the NCCa-ATP channel of an astrocyte, neuron or capillary endothelial cell and methods of using same. More specifically, agonists and antagonists of the NCCa-ATP channel are contemplated. The therapeutic compositions are used to treat cancer, more specifically, a metastatic brain tumor, wherein a tumor-brain barrier is present. Such treatments are contemplated in combination with conventional anti-cancer therapies. Alternatively, the compositions are used to prevent cell death and to treat cerebral edema that result from ischemia, due to interruption of blood flow, to tissue trauma or to increased tissue pressure.

Owner:U S GOVERNMENT REPRESENTED BY THE DEPT OF VETERANS AFFAIRS

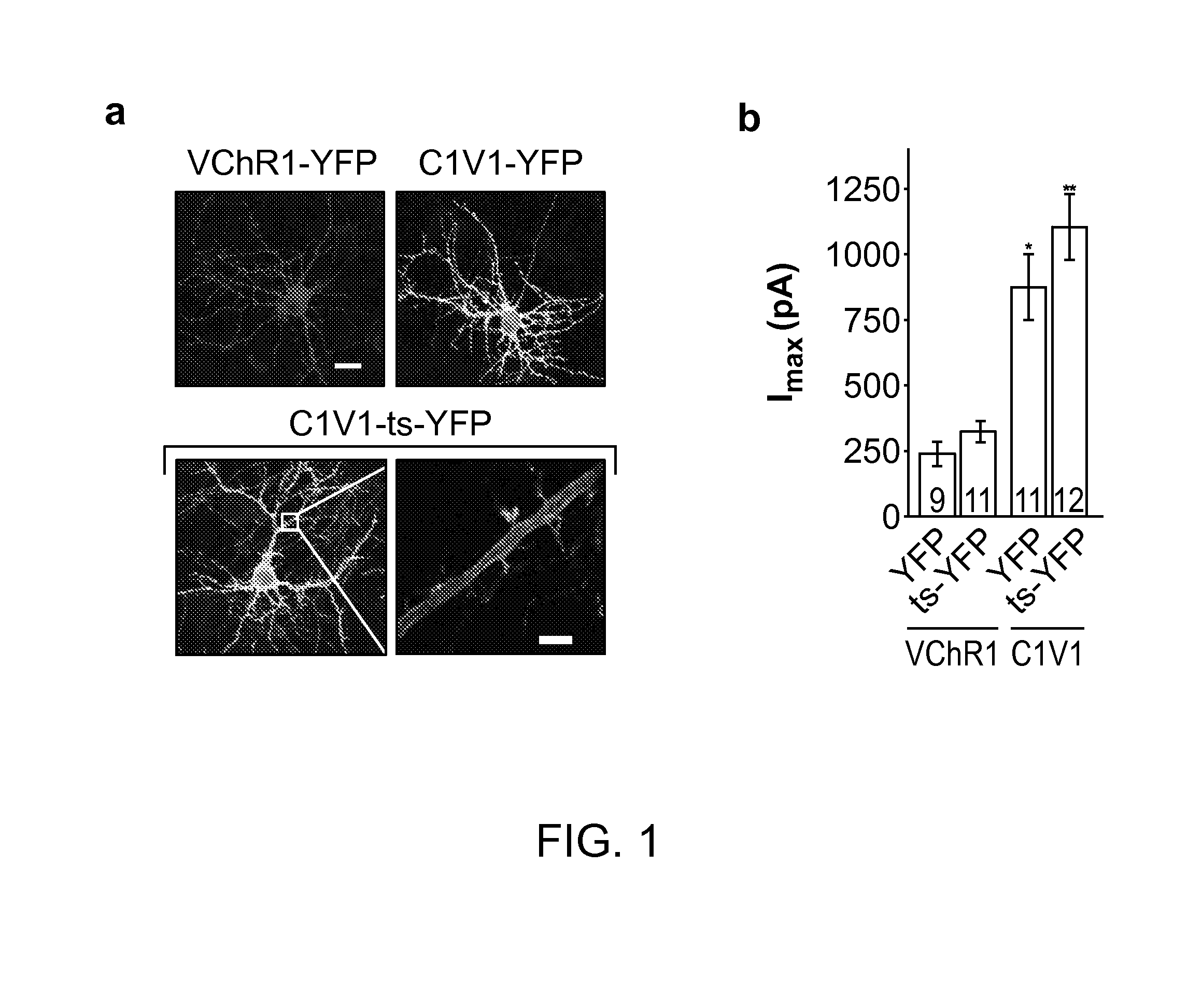

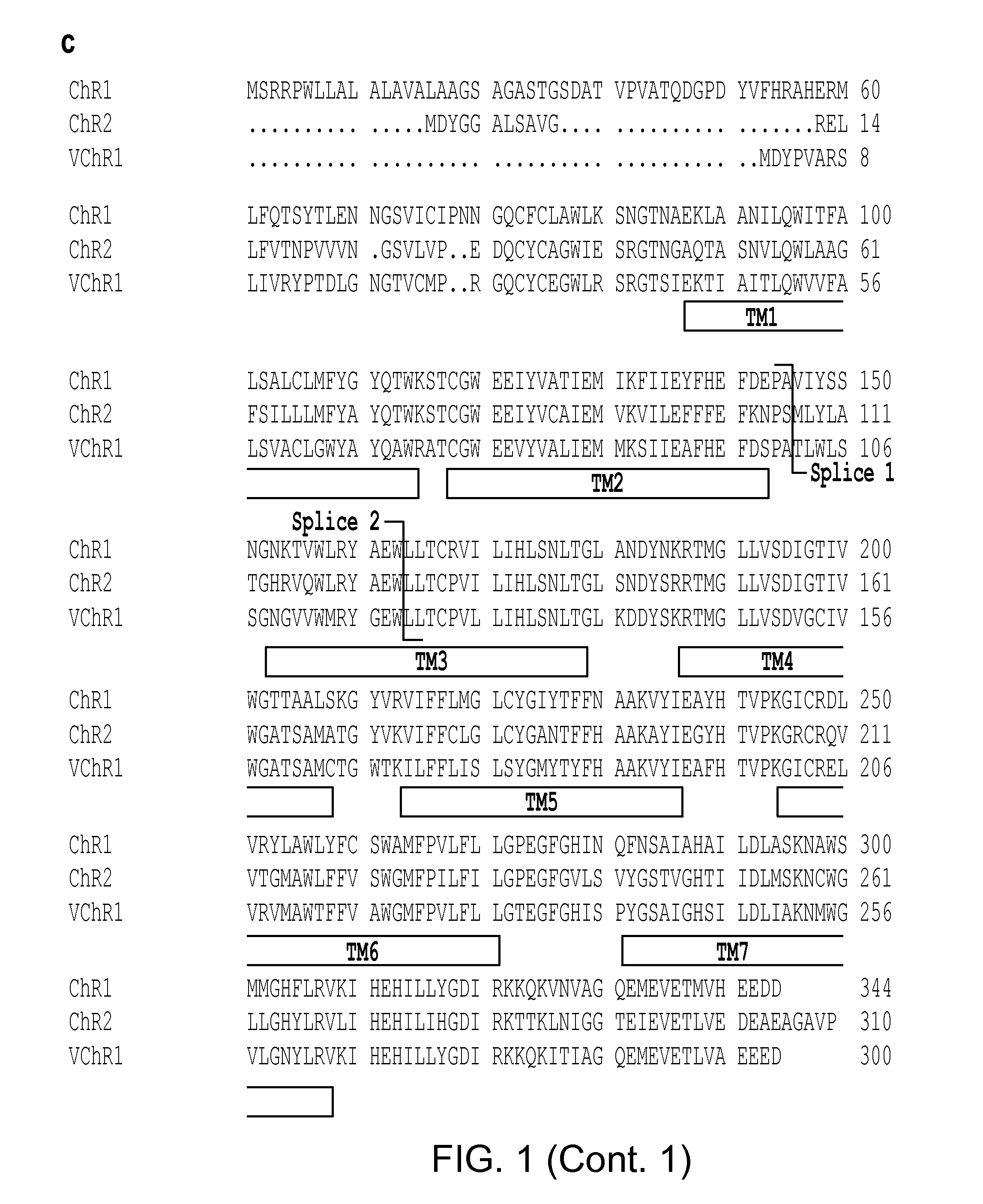

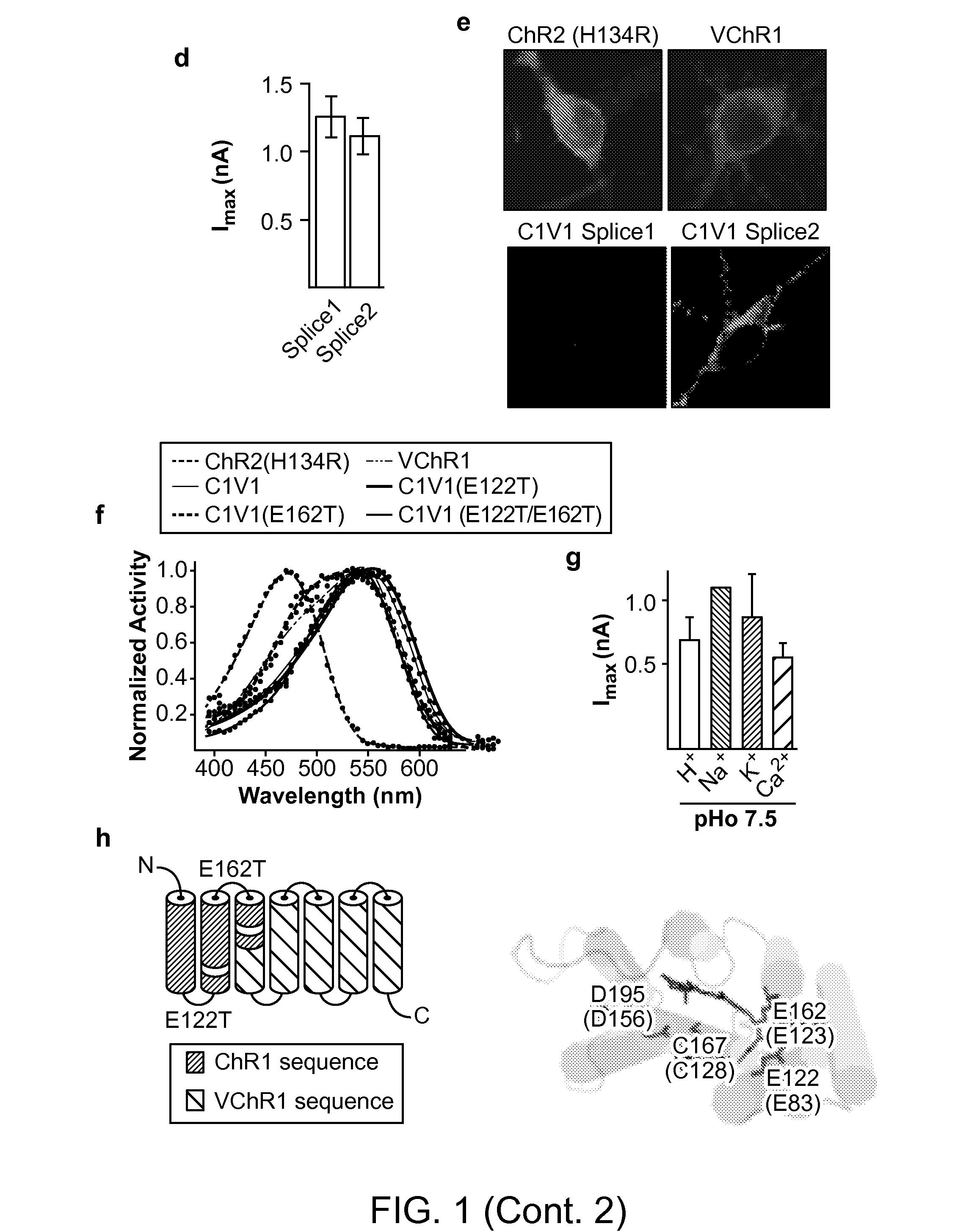

Light-Activated Chimeric Opsins and Methods of Using the Same

ActiveUS20130224821A1Avoid depolarizationCompound screeningNervous disorderLight activatedInhibitory neuron

Provided herein are compositions comprising light-activated chimeric proteins expressed on plasma membranes and methods of using the same to selectively depolarize excitatory or inhibitory neurons.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

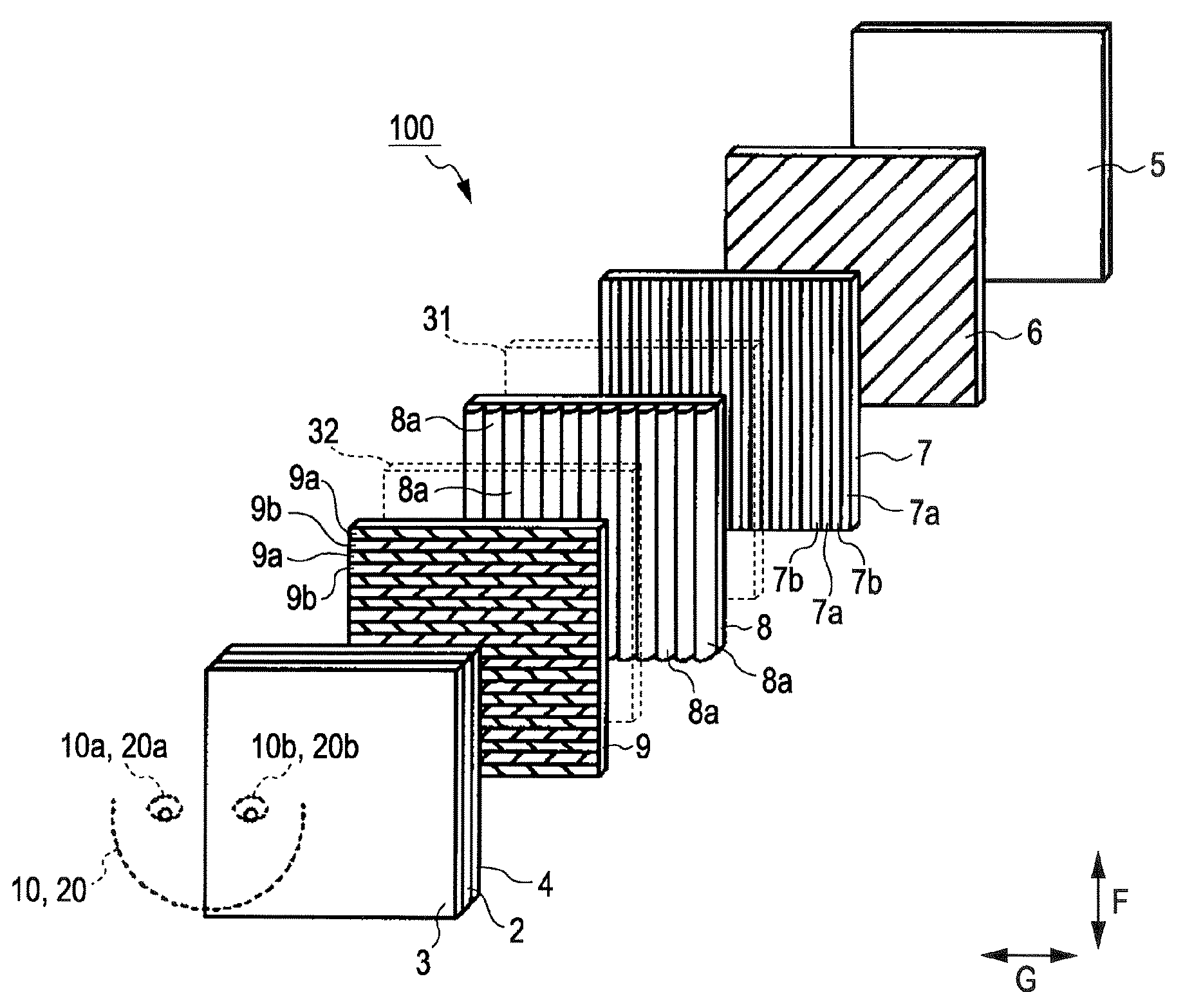

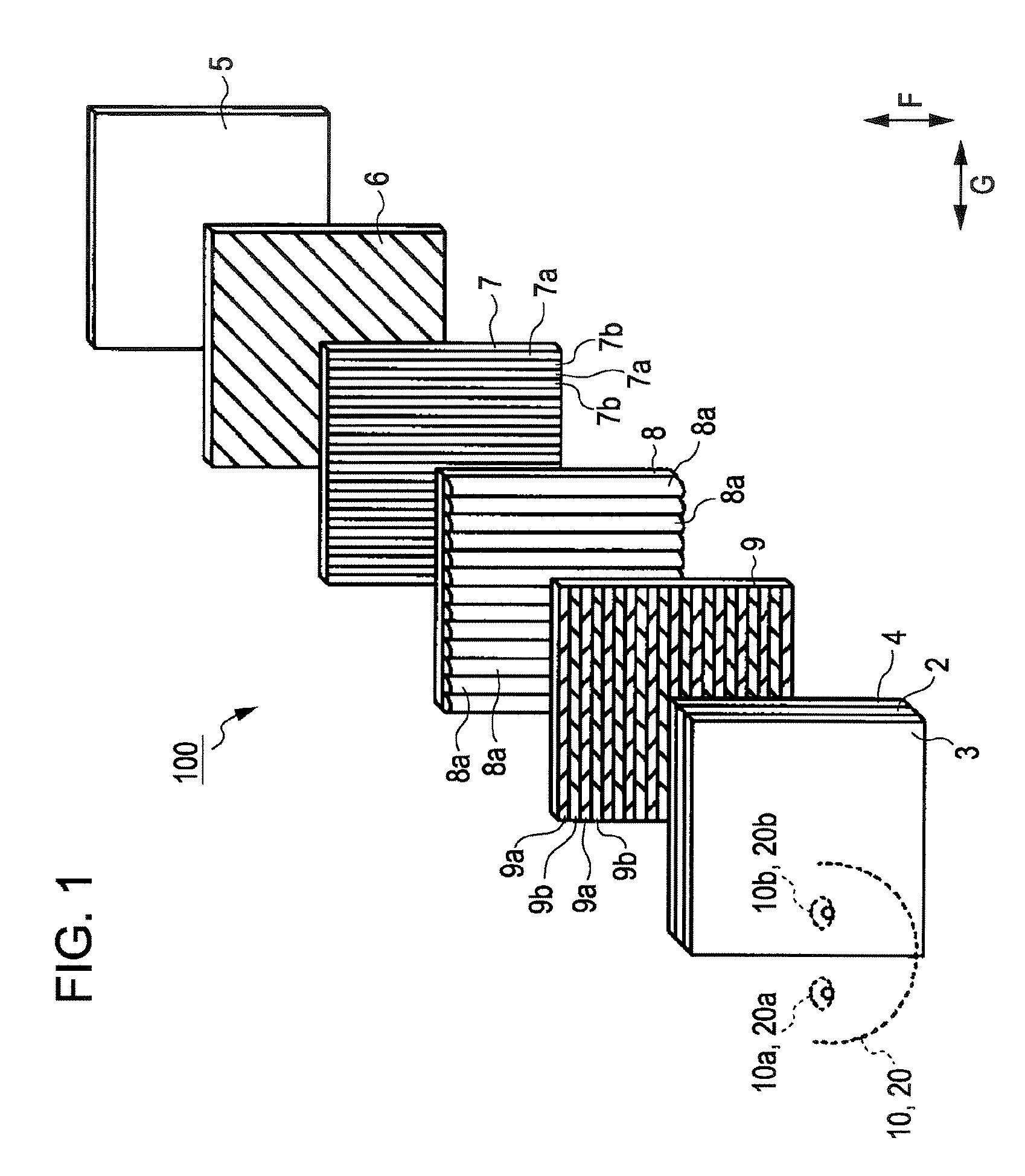

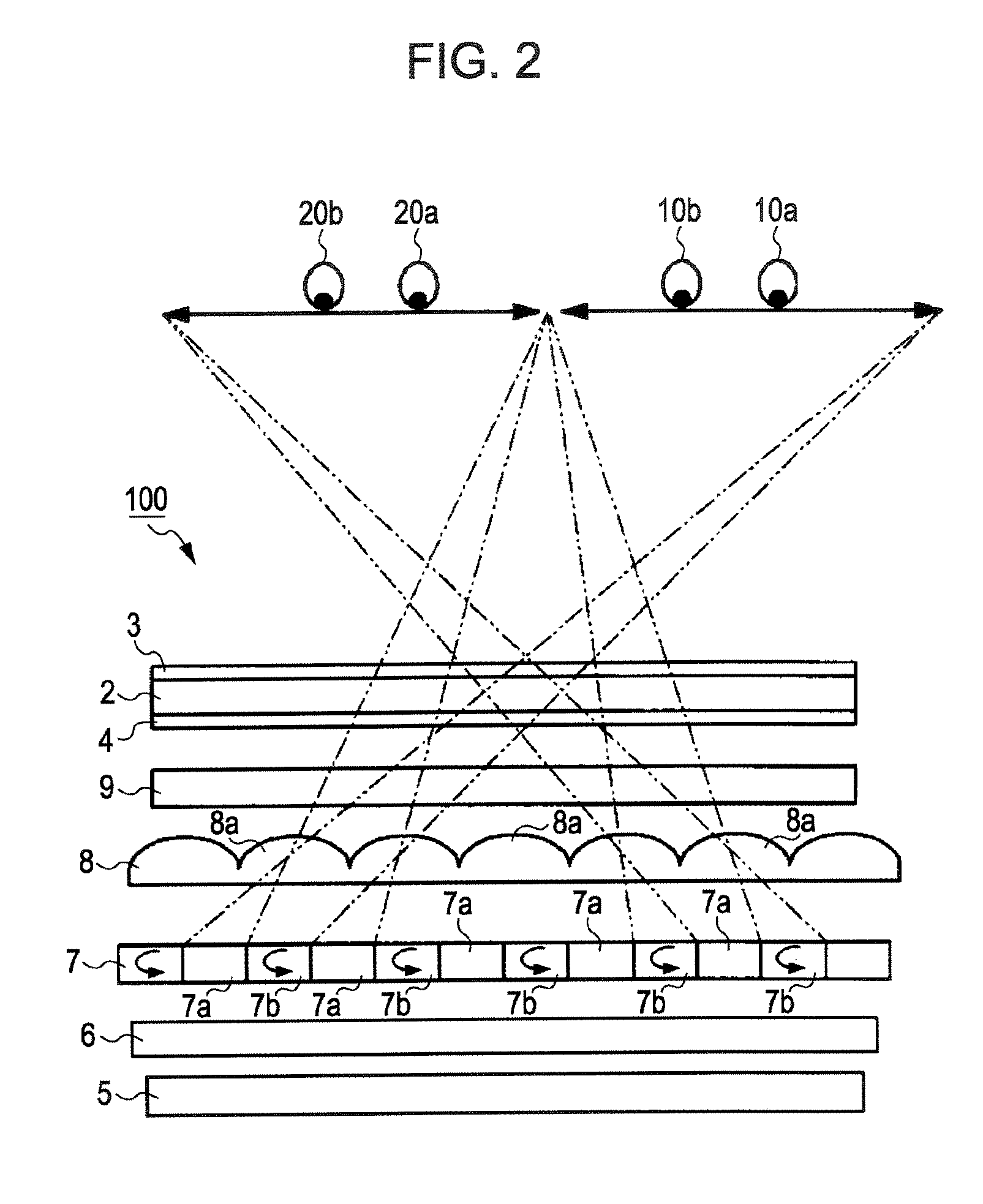

Electrooptic device and electronic device

InactiveUS7697204B2Avoid depolarizationAvoid lightColor television detailsSteroscopic systemsLighting systemControl unit

An electrooptic device includes: a display panel for displaying images; an illumination system for applying light to the display panel; a polarizing-axis control unit disposed between the illuminating system and the display panel, the control unit allowing light having a first polarizing axis of the light emitted from the illuminating system to pass through, and changing part of the light from the illuminating system into light with a second polarizing axis that is substantially orthogonal to the first polarizing axis; a lens disposed between the polarizing-axis control unit and the display panel, the lens including a plurality of linear lens patterns directing the light with the first polarizing axis and the light with the second polarizing axis separated by the polarizing-axis control unit into specified directions; a first polarizing unit disposed between the illumination system and the lens; and a second polarizing unit disposed between the display panel and the lens. Both the polarizing axis of the first polarizing unit and the polarizing axis of the second polarizing unit are substantially parallel to or perpendicular to the extension of the lens patterns.

Owner:EPSON IMAGING DEVICES CORP +1

Pressure-sensitive adhesive and retardation layer-attached polarizing plate, method for manufacturing thereof, optical film, and image display

ActiveUS7976669B2Improve visibilityVisibility can be maintainedLiquid crystal compositionsLaminationAdhesiveDisplay device

A pressure-sensitive adhesive and retardation layer-attached polarizing plate (4) comprises a retardation layer-attached polarizing plate (3) comprising a polarizing plate (2) that comprises an iodine-based polarizer (1) and a transparent protective film laminated on both sides of the polarizer and a method for manufacturing the pressure-sensitive adhesive and retardation layer attached polarizing plate (4).

Owner:NITTO DENKO CORP

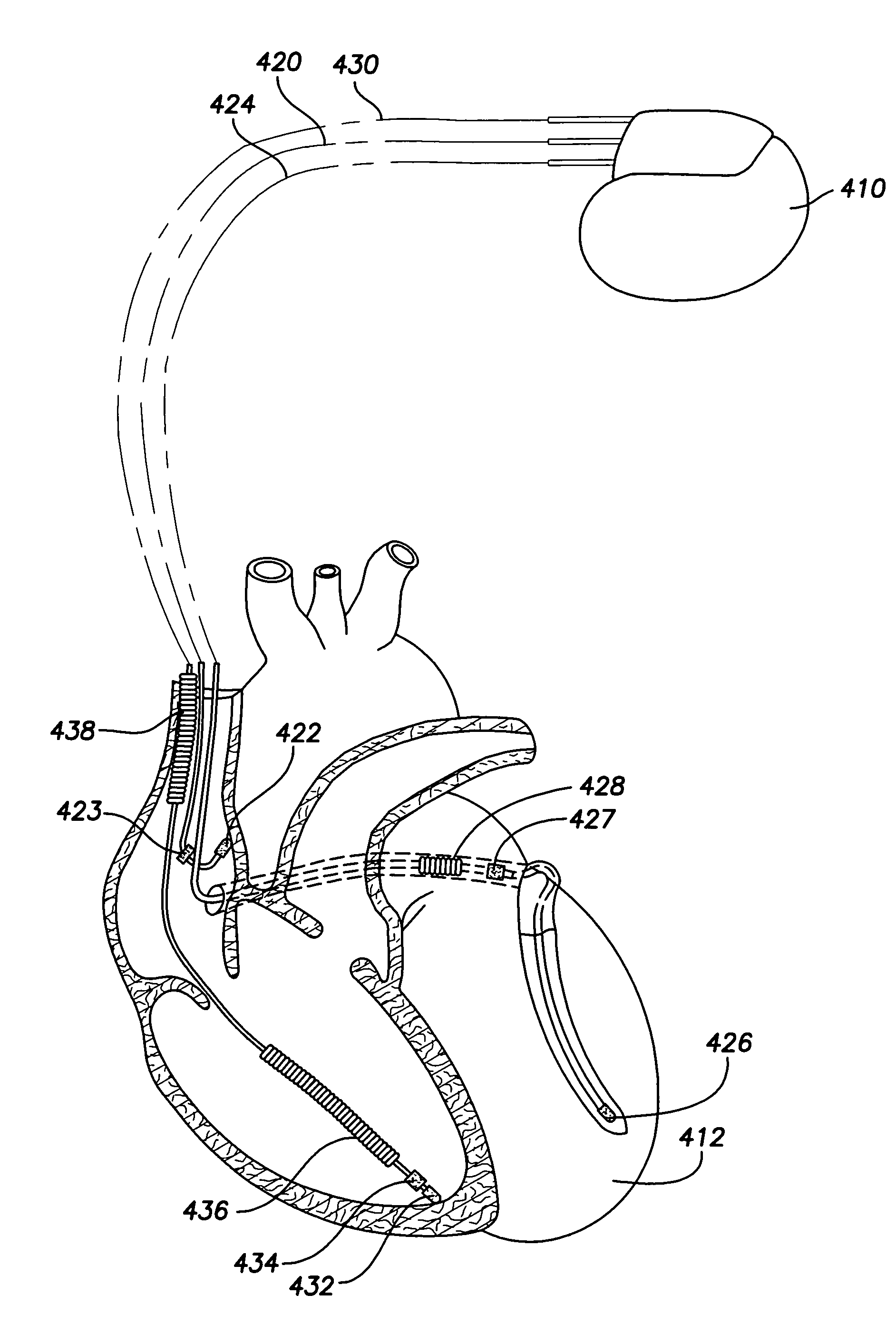

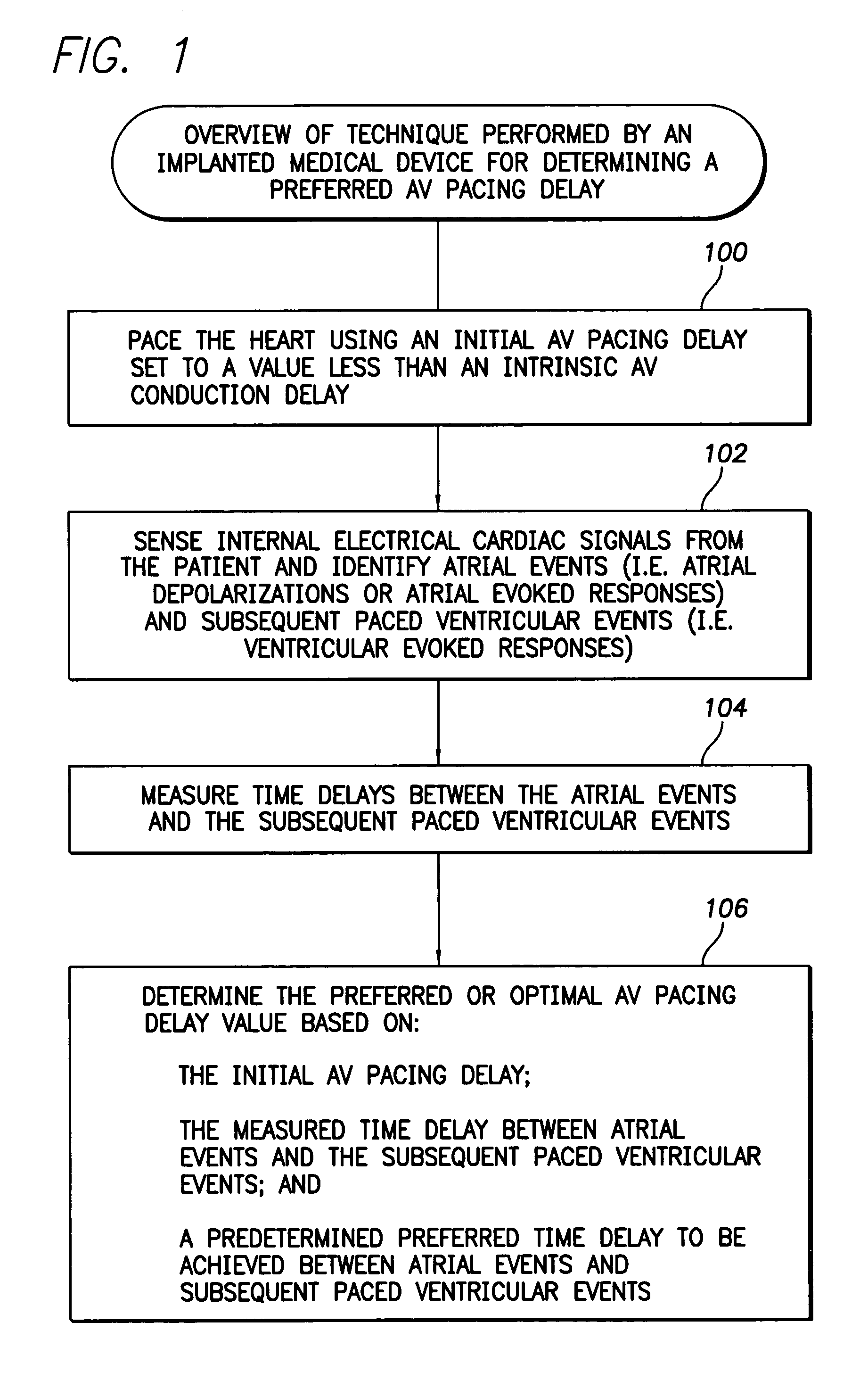

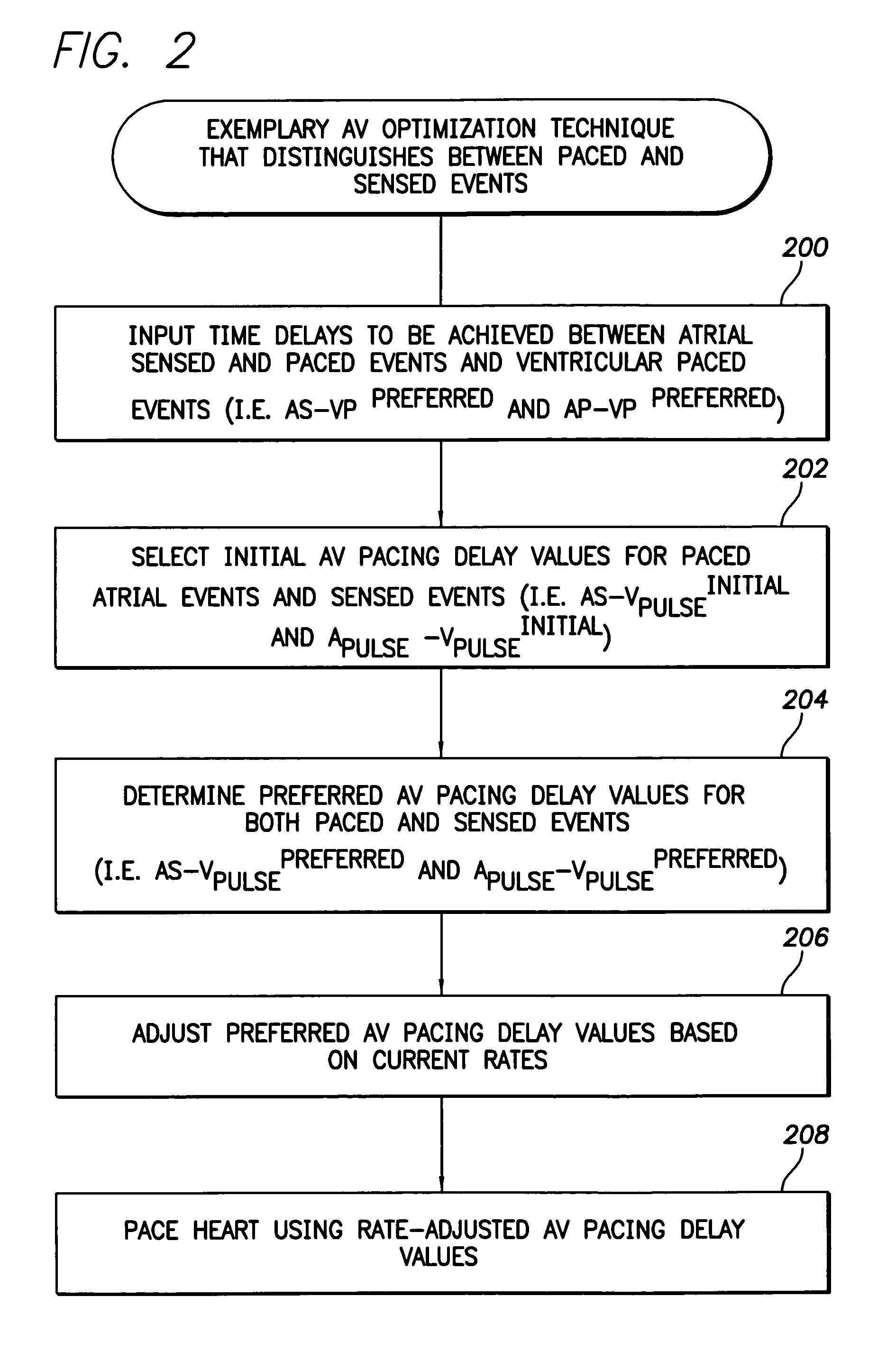

System and method for determining preferred atrioventricular pacing delay values based on intracardiac electrogram signals

InactiveUS7505813B1Intrinsic ventricular depolarization be avoidAvoid depolarizationHeart stimulatorsVentricular pacingCardiac pacing

Techniques are provided for use by an implantable medical device for determining optimal or preferred atrioventricular (AV) pacing delay values for use in pacing the heart. Briefly, the atria and ventricles are paced using an initial AV pacing delay set to a value less than an intrinsic AV conduction delay so that intrinsic ventricular depolarizations are avoided. An internal electrical cardiac signal is sensed and atrial evoked responses and subsequent ventricular evoked responses are identified therein. Time delays between the atrial and ventricular evoked responses are measured and then a preferred or optimal AV pacing delay value is determined based on: the initial AV pacing delay; the measured time delays between the atrial and ventricular evoked responses; and on a predetermined preferred time delay to be achieved between atrial and ventricular evoked responses. Similar procedures are employed in connection with atrial sensed events. A calibration procedure is also described.

Owner:PACESETTER INC

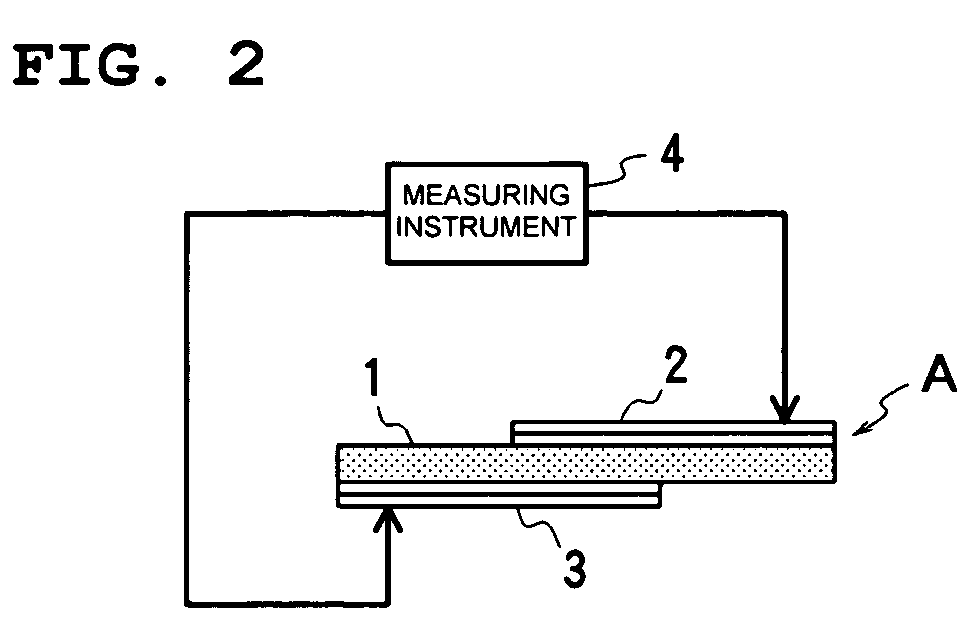

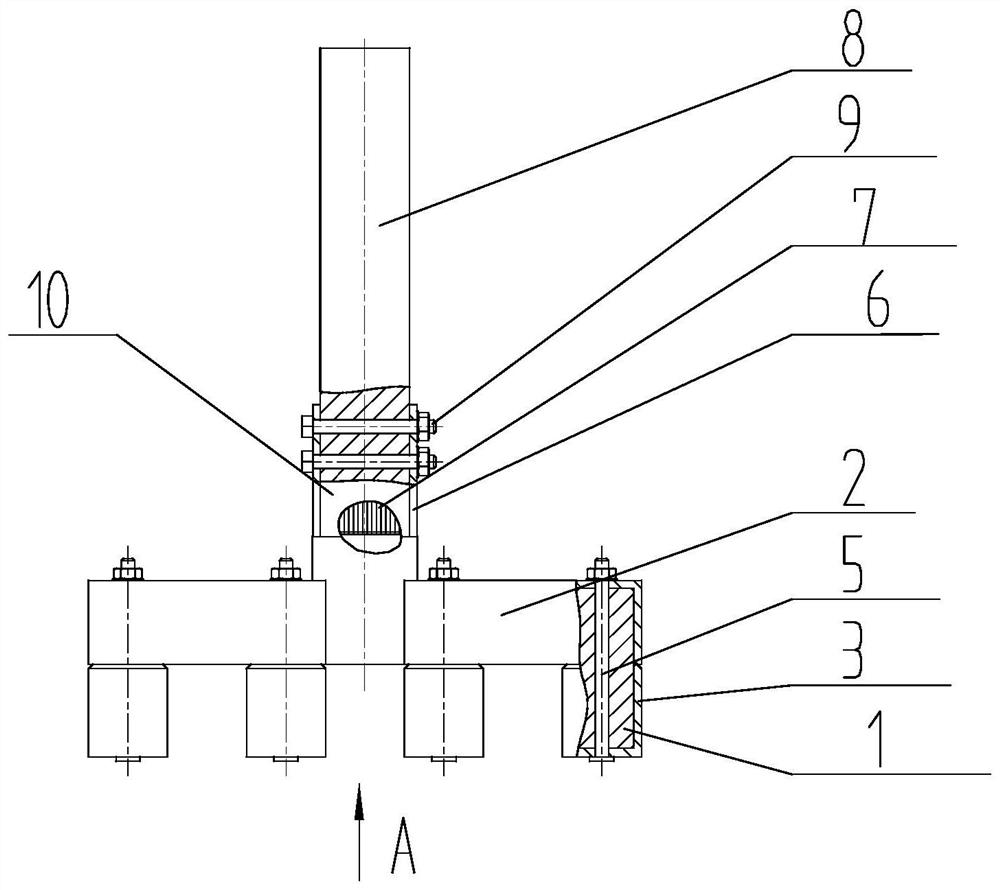

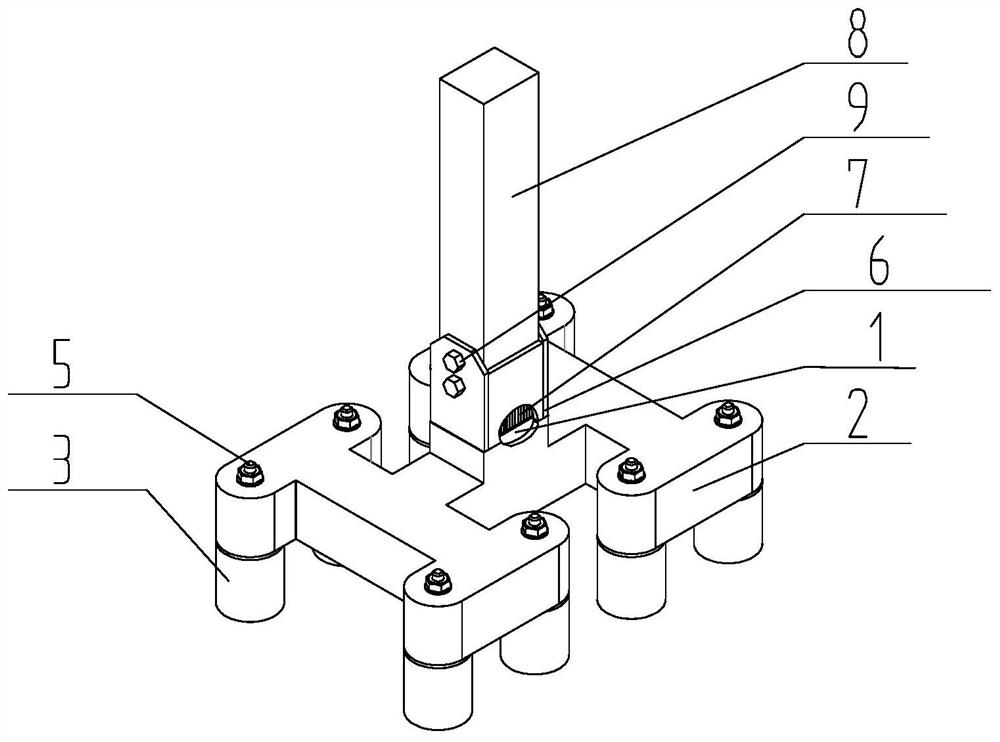

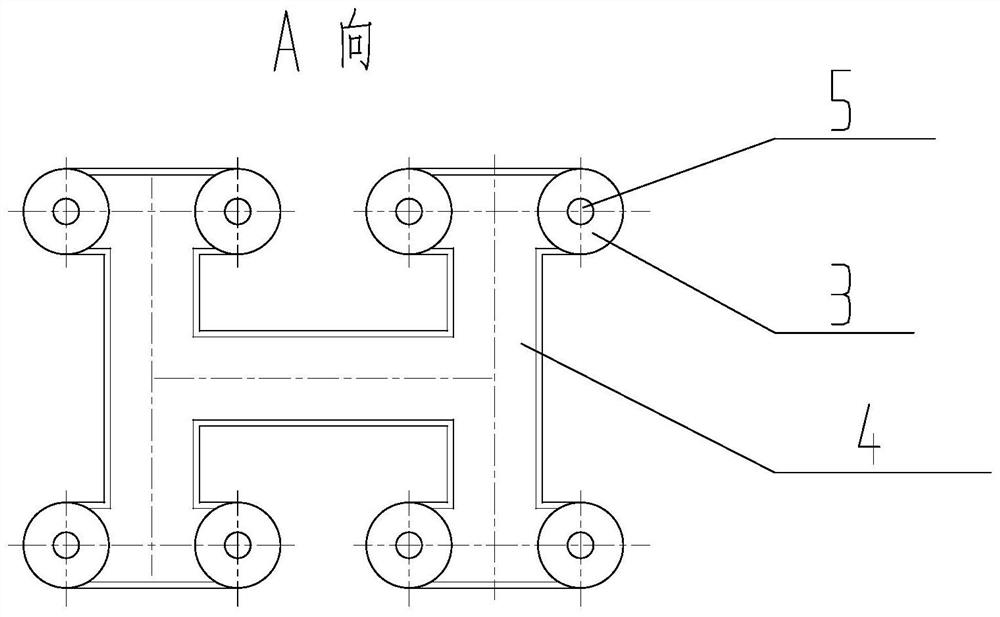

Temperature-varying polarization device and method for piezoelectric element

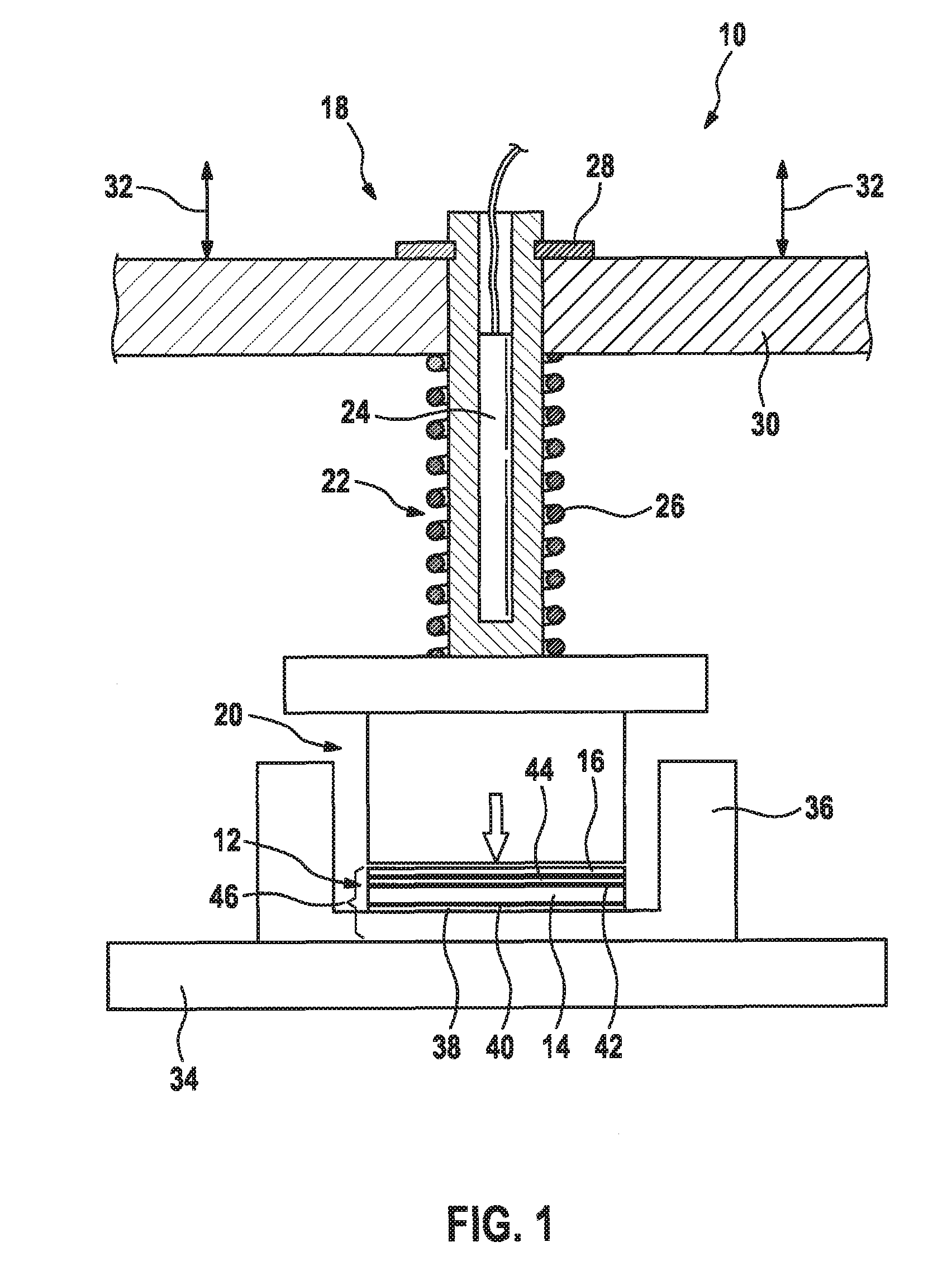

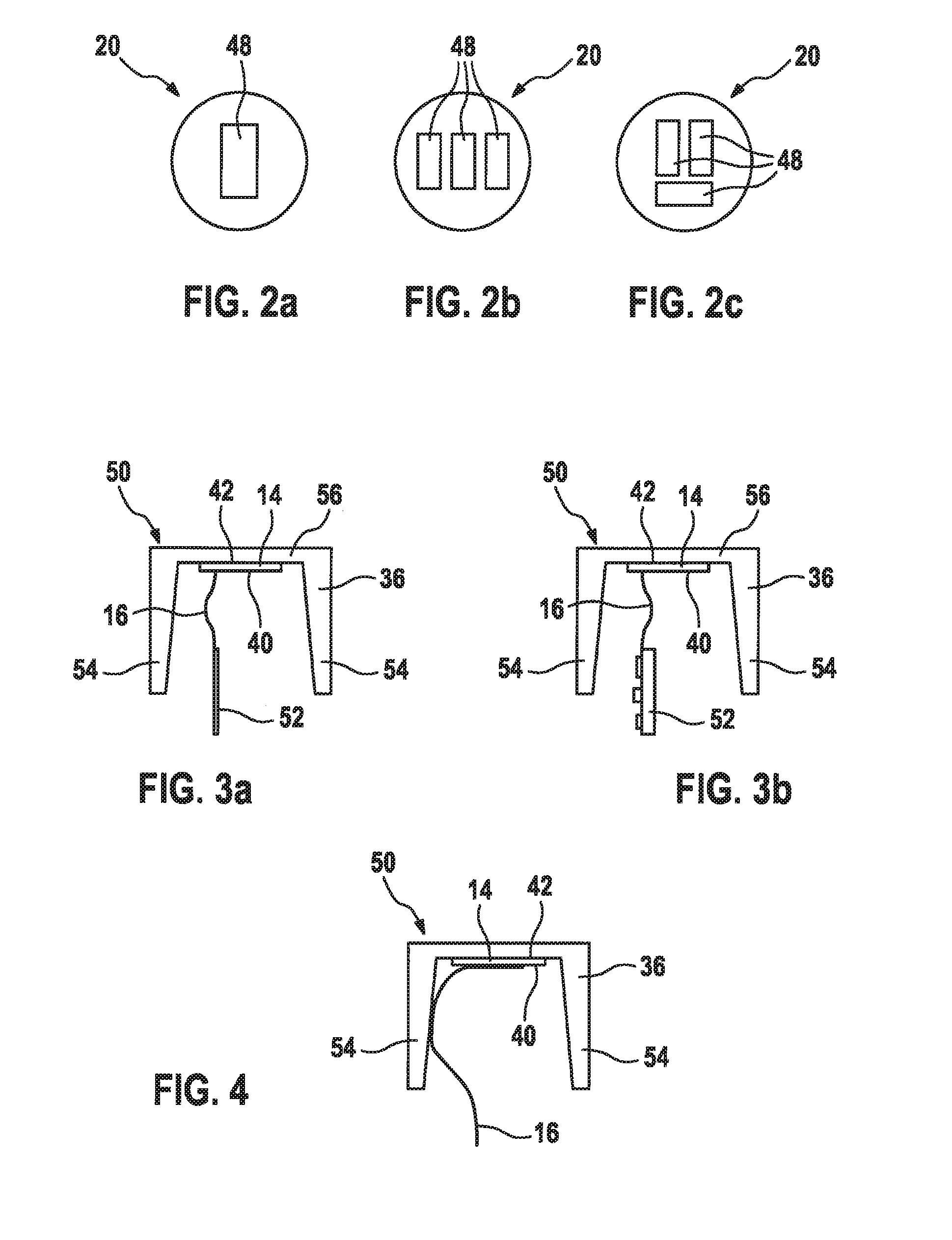

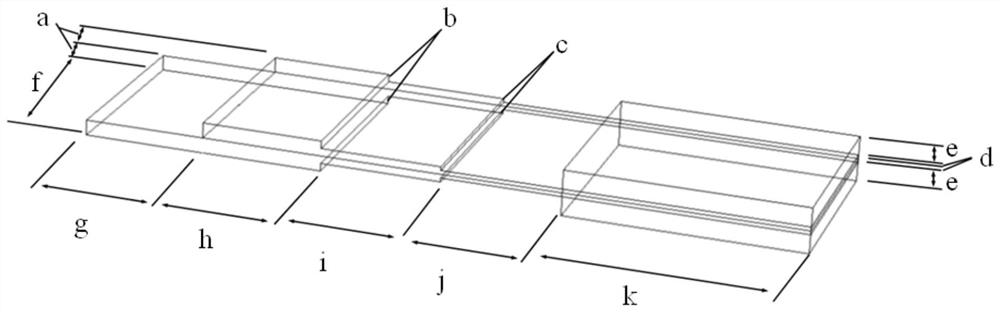

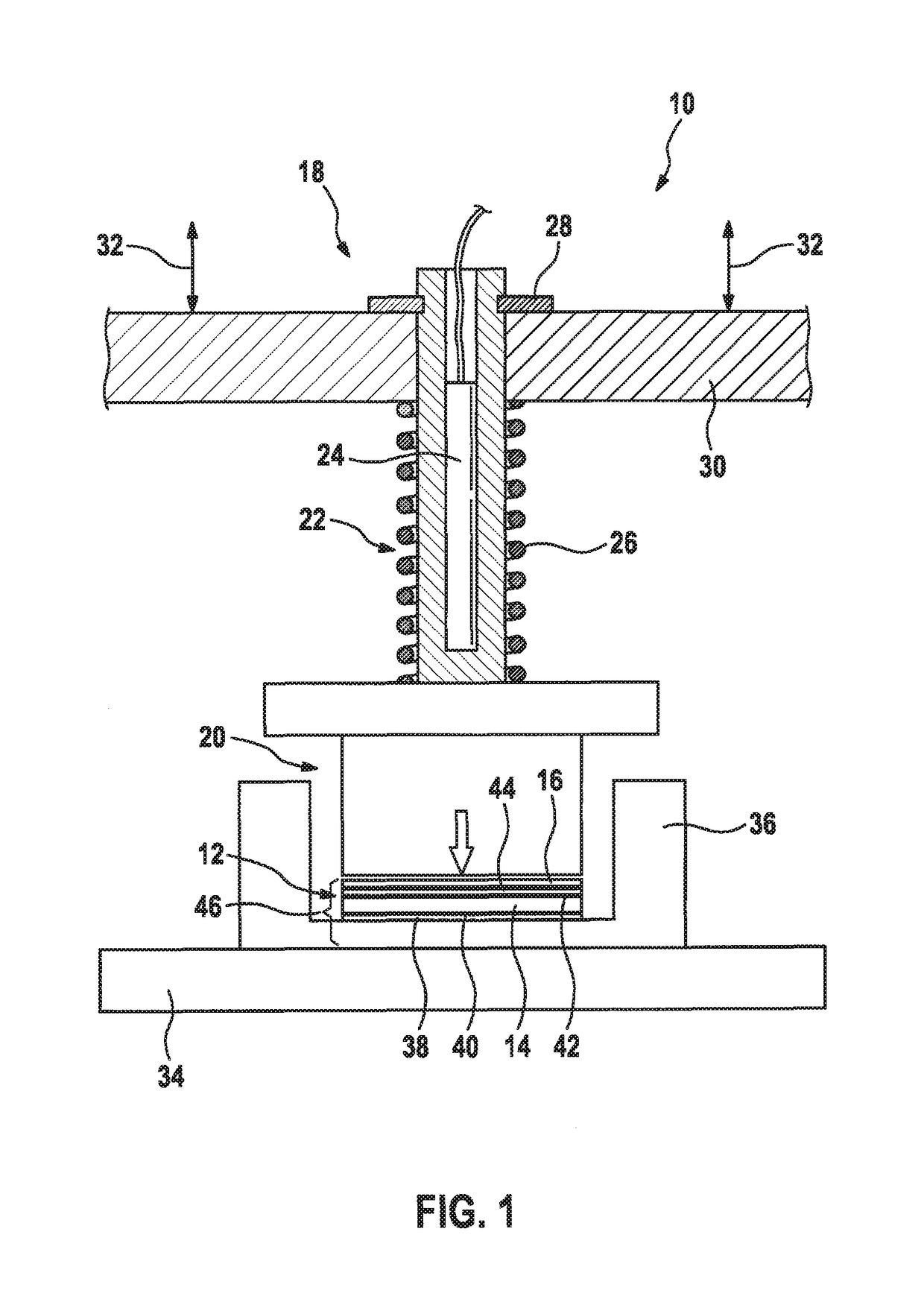

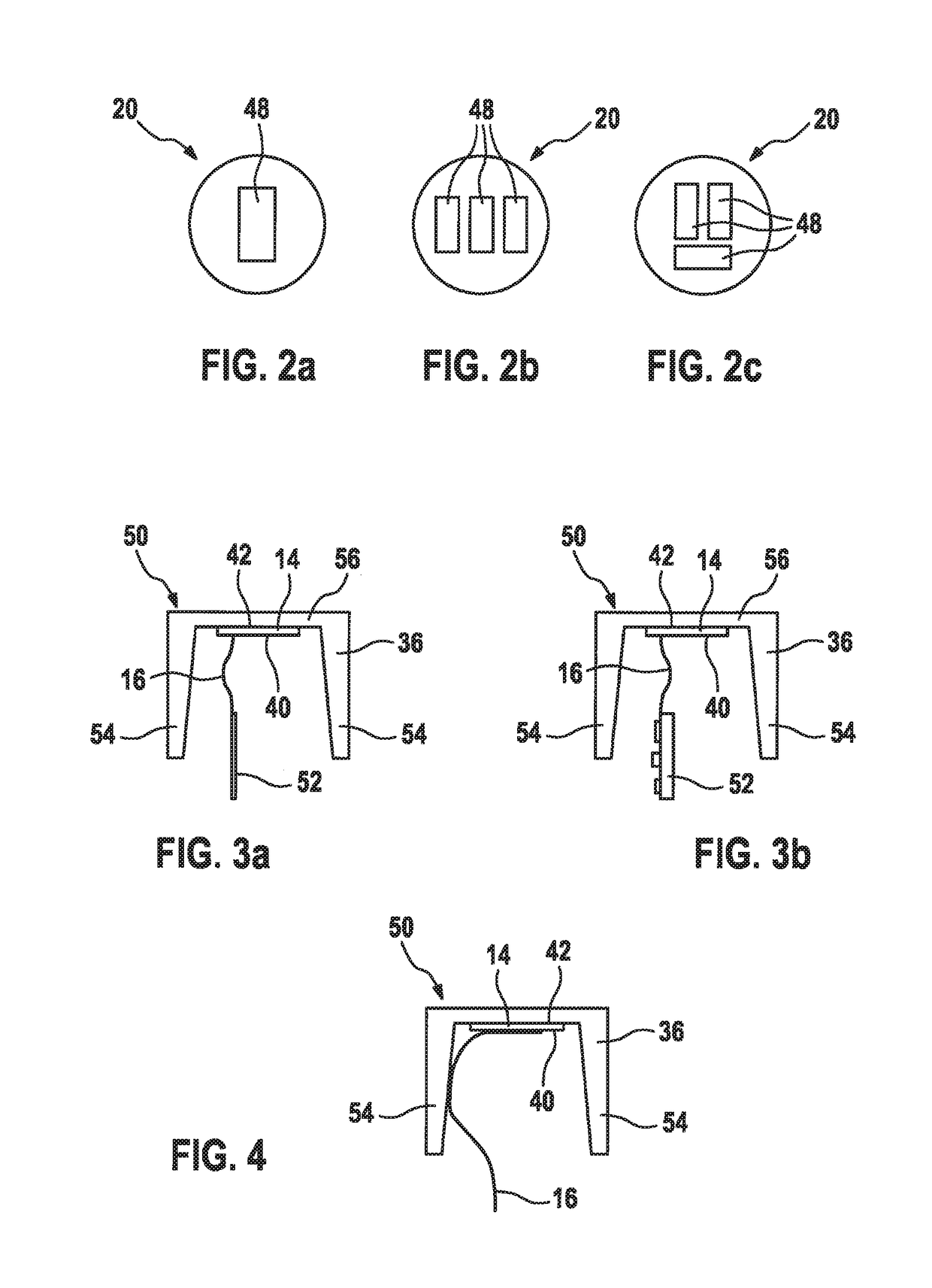

ActiveCN109037432ARapid coolingAvoid depolarizationPiezoelectric/electrostrictive/magnetostrictive devicesEngineeringSilicone oil

The invention discloses a temperature-varying polarization device and method for a piezoelectric element. The temperature-varying polarization device for the piezoelectric element comprises a controlassembly, wherein the control assembly comprises a pressurizing unit and a control unit; a polarization cell for containing silicone oil; and a polarization assembly comprises a fixed seat and a moving assembly connected with the fixed seat. The pressurizing unit is electrically connected with the fixed seat. The moving assembly is electrically connected with the control unit. The moving assemblydrives the fixed seat to move into or out of the silicone oil in the container. The variable temperature polarization device of the piezoelectric element of the present invention is aimed at achievingrapid cooling without reducing piezoelectric performance.

Owner:GOERTEK MICROELECTRONICS CO LTD

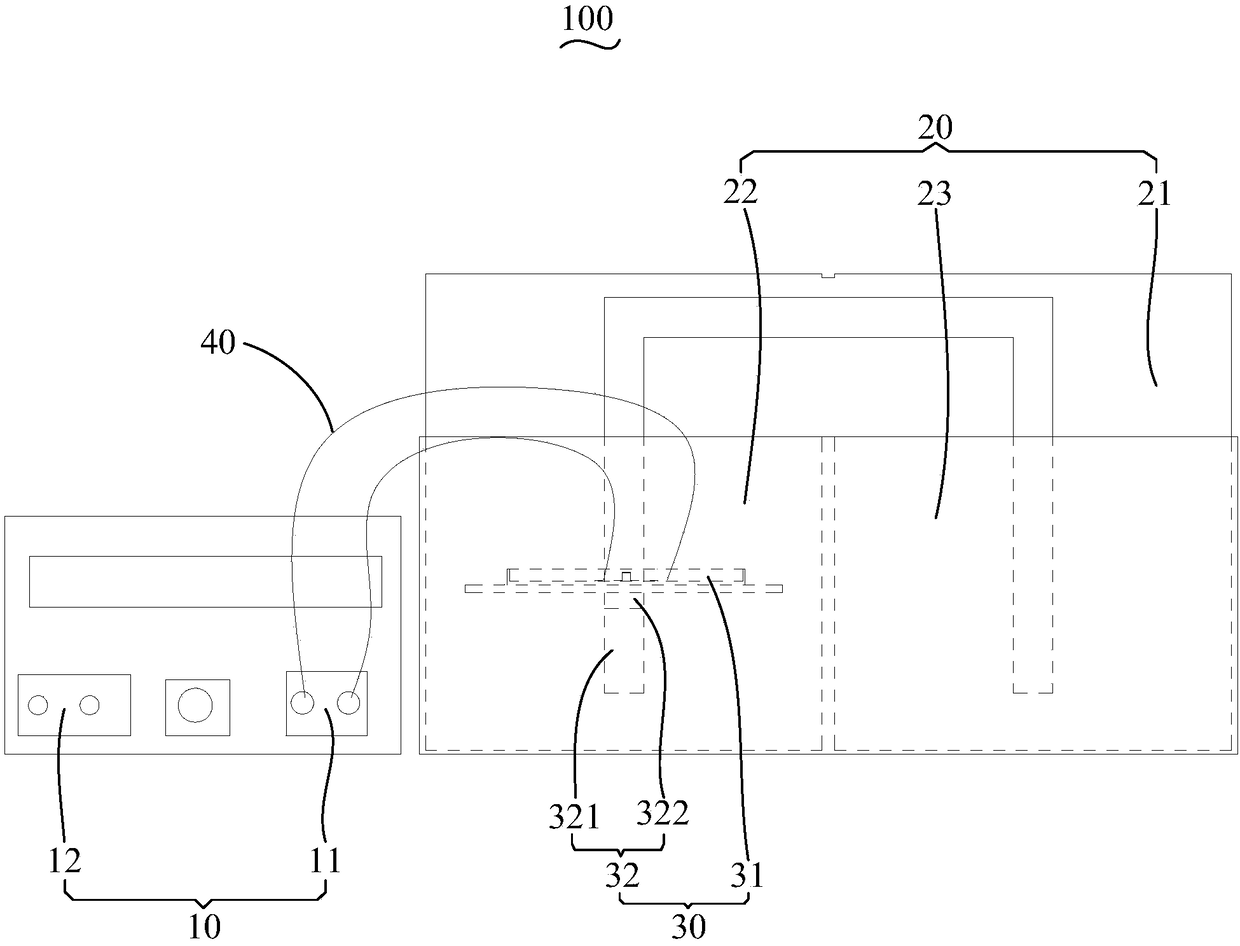

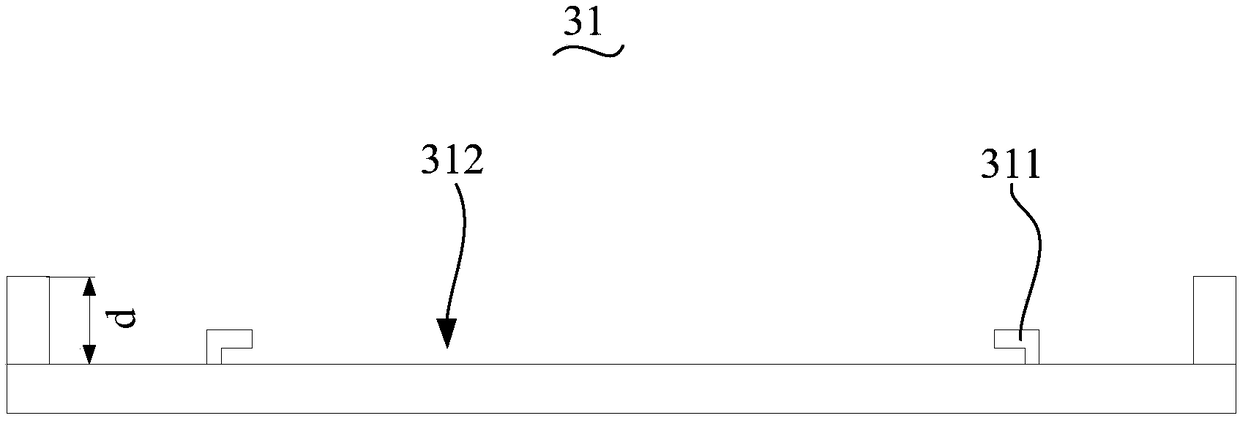

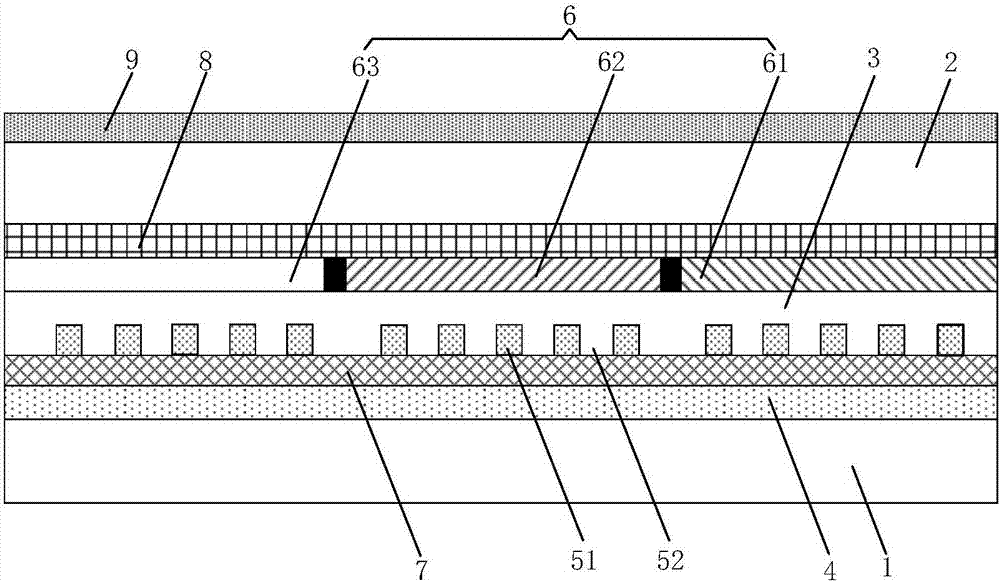

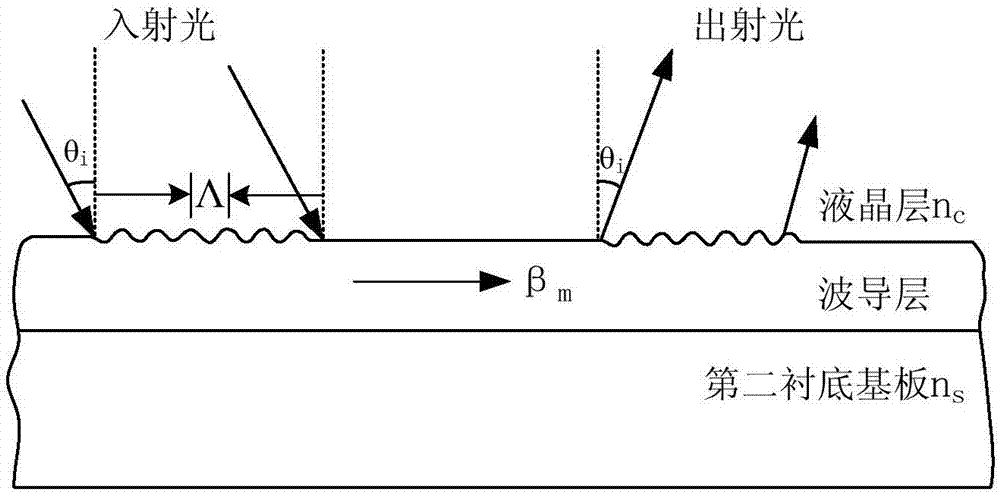

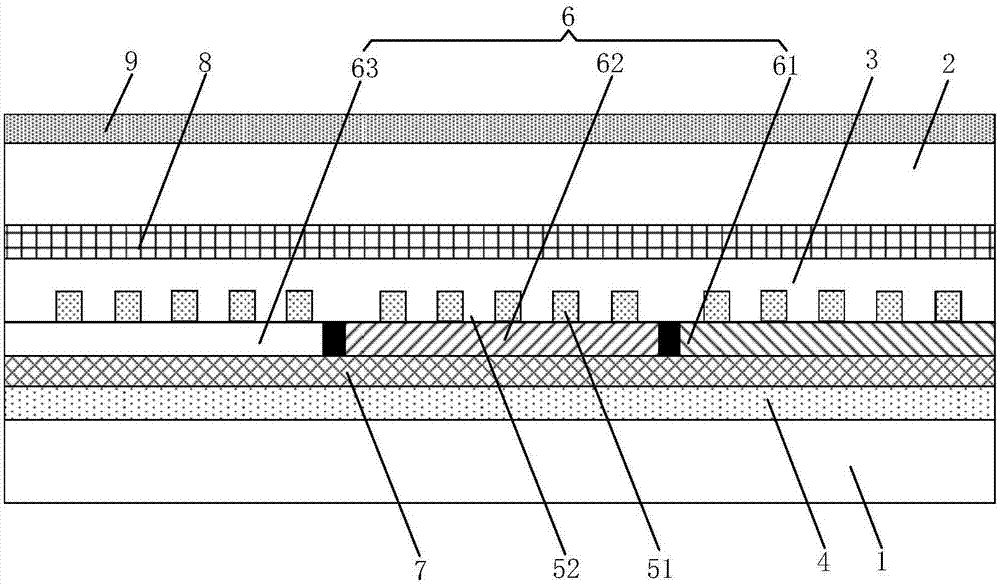

Display panel and display device

ActiveCN106292049BImprove transmittanceAvoid depolarizationStatic indicating devicesPlanar/plate-like light guidesGratingRefractive index

The invention discloses a display panel and a display device. The display panel includes: including: a first base substrate, a liquid crystal layer, a waveguide layer, a grating layer, a quantum dot color filter layer, a first electrode and a second electrode, and the first electrode and the second electrode are used for Adjusting the refractive index of the liquid crystal layer; the grating layer is used to control light coupling out of the waveguide layer, and the coupling efficiency of the waveguide layer for coupling out light depends on the refractive index of the liquid crystal layer and the refractive index of the grating layer The difference is determined. In the present invention, there is no need to set polarizers in the display panel, which avoids the problem of depolarization of quantum dots, so that quantum dot materials can be applied to liquid crystal display devices; the transmittance of the display panel is improved; and the thickness of the liquid crystal box can be set The thinner, which improves the response time of the liquid crystal.

Owner:BOE TECH GRP CO LTD

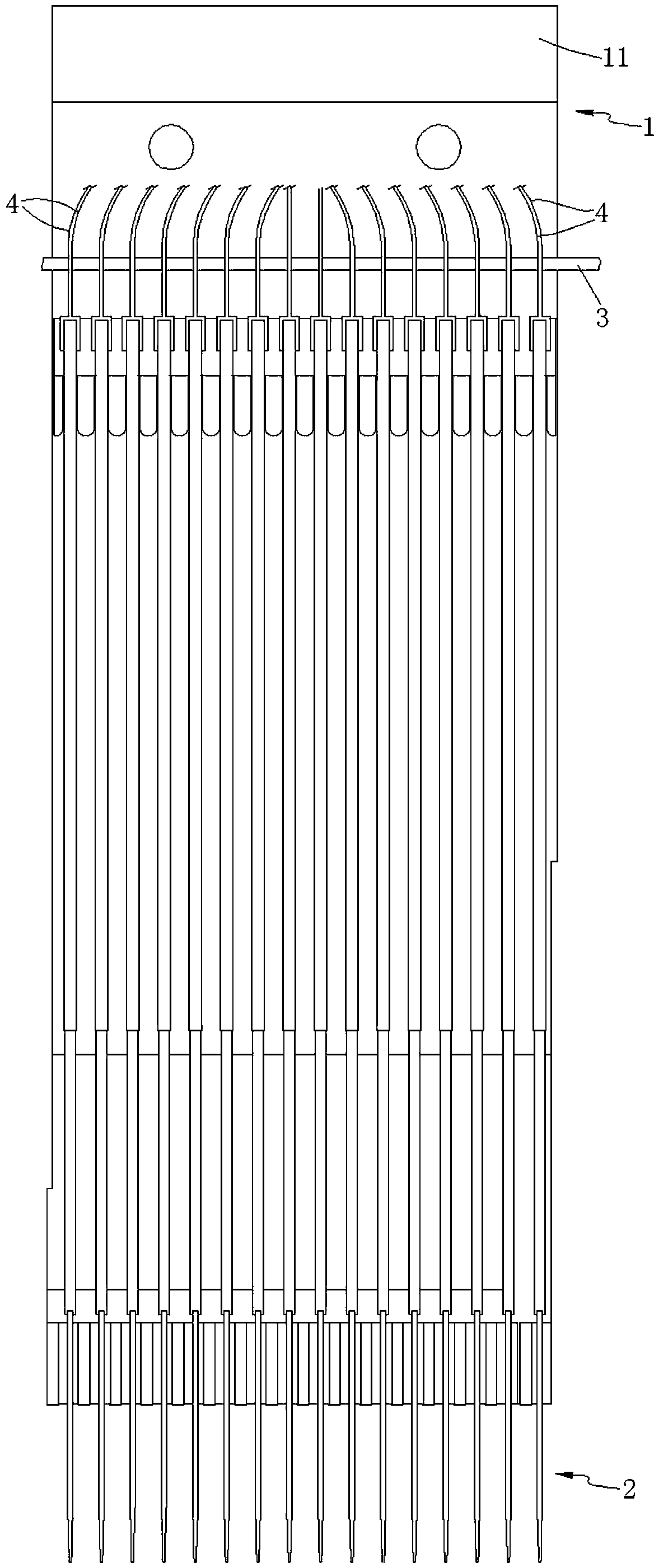

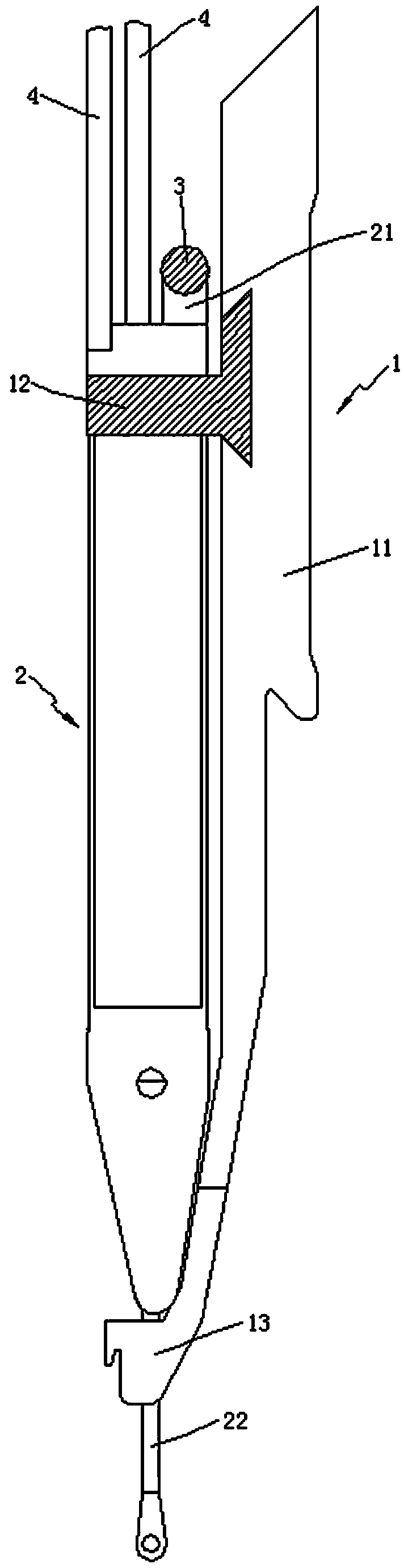

Jacquard needle piece of warp knitting machine

The invention discloses a jacquard needle piece of a warp knitting machine. The jacquard needle piece of the warp knitting machine comprises a jacquard needle bed and a plurality of piezoelectric ceramic needle selecting pieces. The jacquard needle bed comprises a base plate, a needle embedding block and a limiting block, and one piezoelectric ceramic needle selecting piece is embedded in each needle embedding groove in the needle embedding block and one corresponding limiting groove in the limiting block. Each piezoelectric ceramic needle selecting piece comprises a middle substrate, a yarn guide needle and piezoelectric ceramic pieces arranged on the two sides of the middle substrate, each middle substrate is a carbon fiber substrate made of conductive carbon fiber materials, the middle substrate of each piezoelectric ceramic needle selecting piece is electrically connected with the electrodes in the piezoelectric ceramic pieces arranged on the two sides of the middle substrate, the middle substrates of all the piezoelectric ceramic needle selecting pieces are integrally connected through first guide wires to be electrically connected with the negative electrode of a driving power source of the warp knitting machine, and the outer electrodes of the piezoelectric ceramic pieces on the two sides of each middle substrate are respectively and electrically connected with the positive electrode of the driving power of the warp knitting machine through second guide wires. The jacquard needle piece of the warp knitting machine is low in manufacturing cost, high in production efficiency, long in service life, and capable of avoiding the accidents of depoissonization, leakage current and short circuit of the piezoelectric ceramic pieces.

Owner:常州市斯威芙特制针科技有限公司

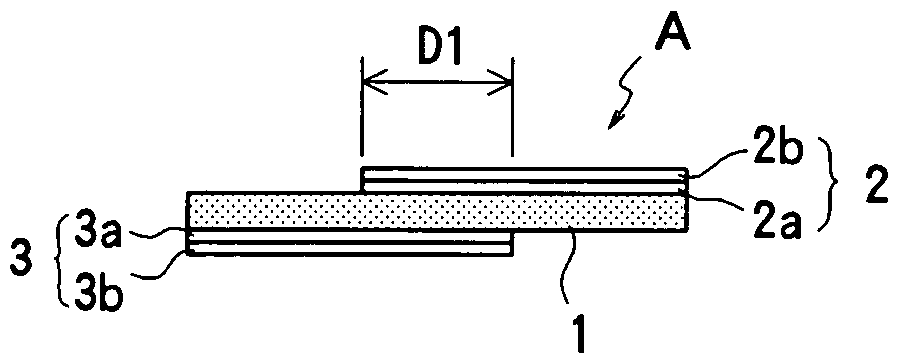

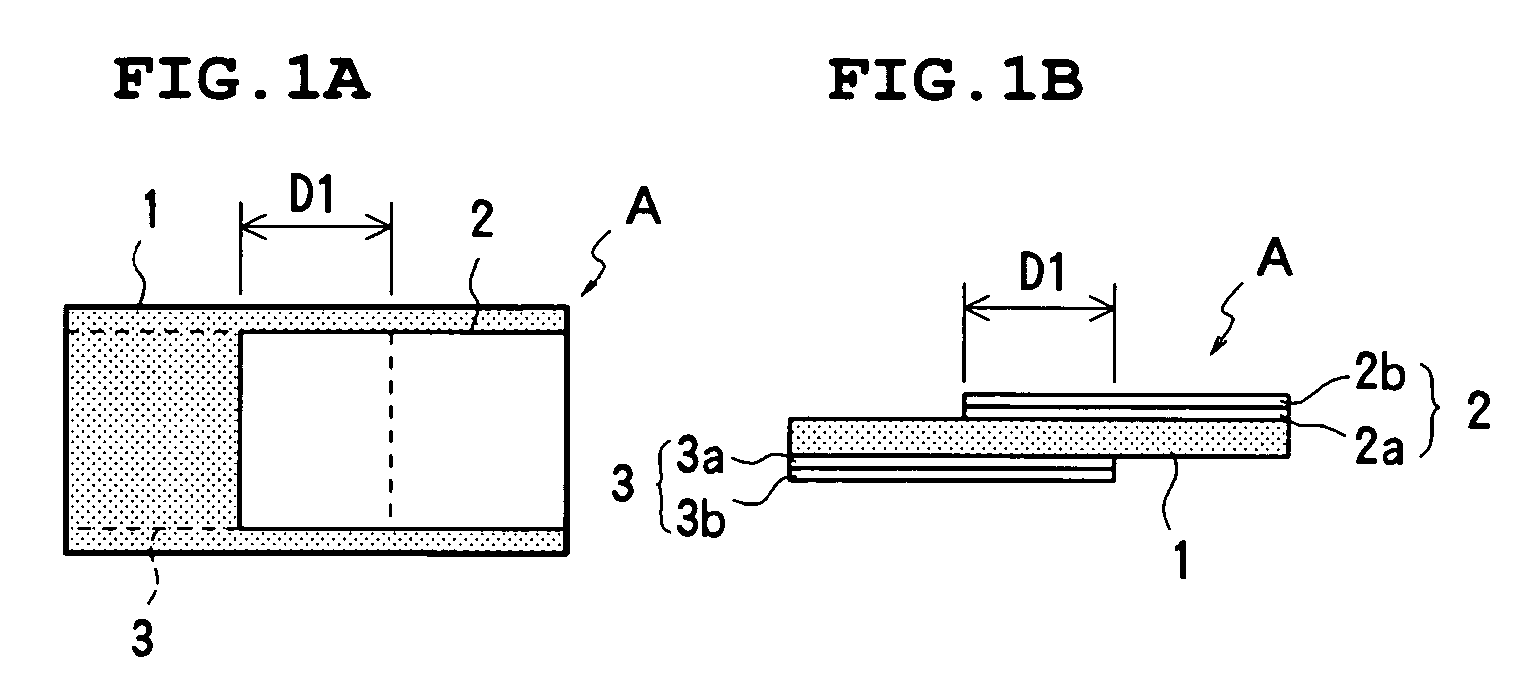

Method for manufacturing piezoelectric resonator

ActiveUS20060048358A1Easy to adjustImprove frequency measurement accuracyPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyVibrating electrodePiezoelectric resonators

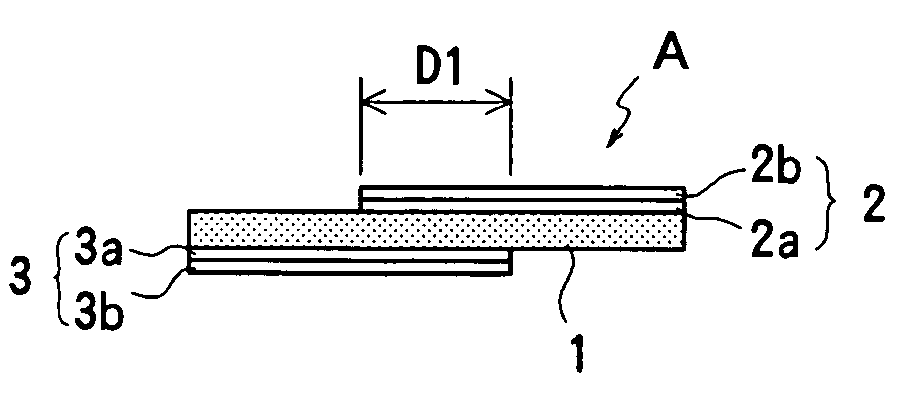

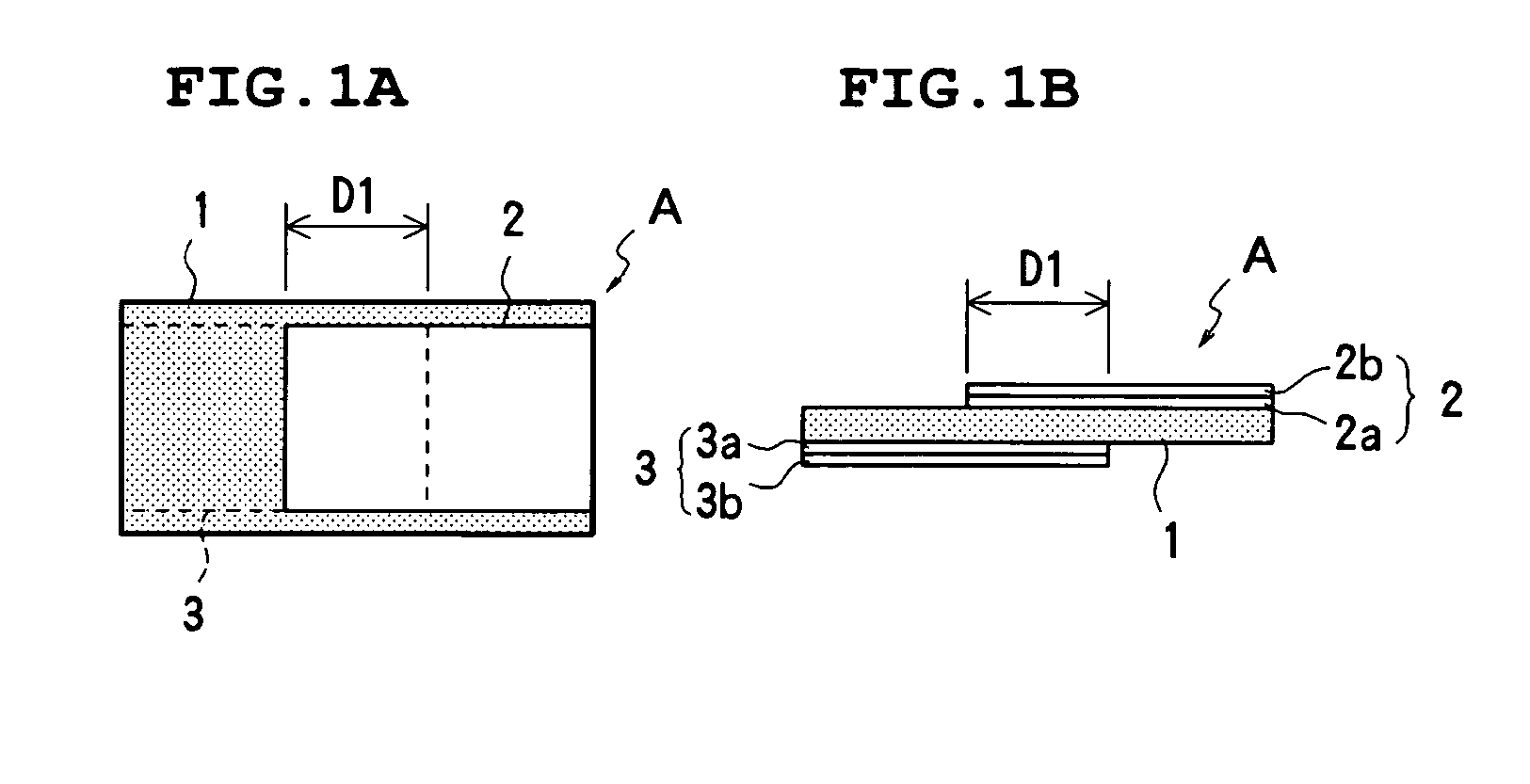

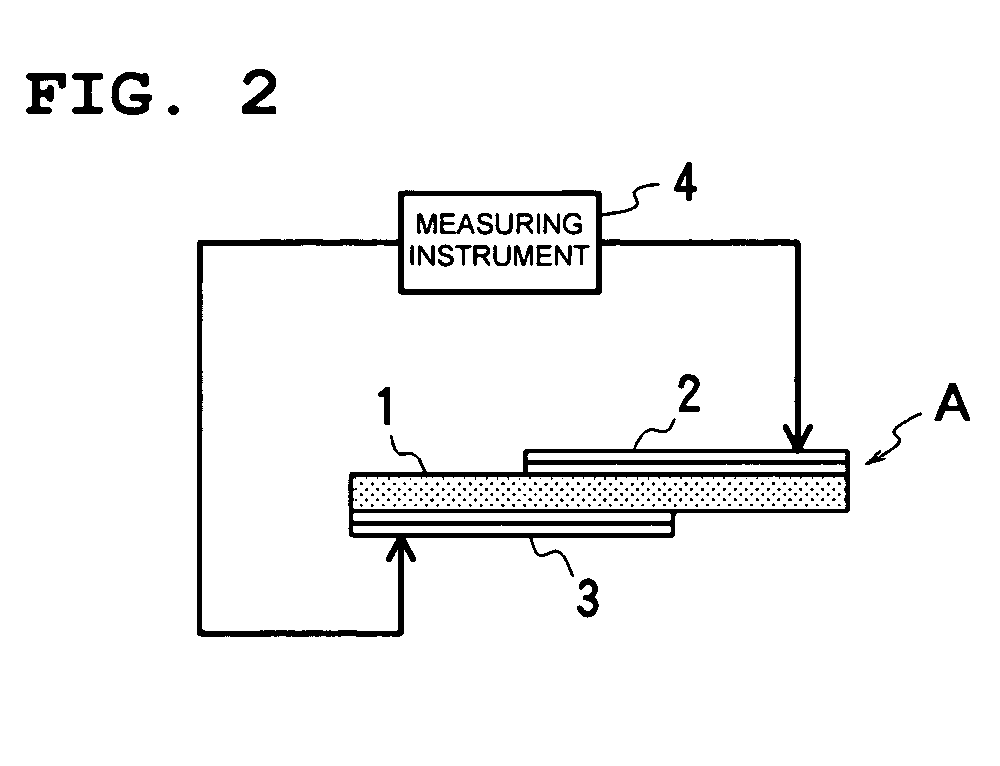

A method of manufacturing a piezoelectric resonator includes forming first electrodes larger than vibrating electrodes in an area D1 including the vibrating electrodes on obverse and reverse surfaces of a piezoelectric substrate, and measuring the resonant frequency fr1 of a resonator including the first electrodes. The thickness of a metallic thin film required for frequency adjustment is determined based on the measured resonant frequency. Then, second electrodes formed of the metallic thin film having the determined thickness are formed in an area D2 including at least the vibrating electrodes of the piezoelectric substrate. By removing unnecessary portions of the first and second electrodes, a pattern of the resulting vibrating electrodes is formed. Thus, high-accuracy frequency adjustment can be achieved without the need for complicated positioning.

Owner:MURATA MFG CO LTD

Self-injection structure for realizing isotropic medium output linearly polarized single-frequency laser

The invention provides a self-injection structure for realizing isotropic medium output linearly polarized single-frequency laser and relates to the self-injection structure of a laser, in particular to a Tm<3+>:YAG (yttrium aluminum garnet) laser which performs end-pumped single-frequency self-injection. 785nm light enters a crystal from an end surface; end pumping is performed; a single longitudinal mode is selected by combining an F-P etalon with a volume grating, wherein the volume grating serves as an output cavity lens; after the light enters a light splitter, the generated laser enters a 1 / 2 wave plate and a Glan prism to form linearly polarized light; and a small part of light is reflected by a full-reflecting lens through a partial through lens, so that the linearly polarized light is re-injected into the crystal to be continuously oscillated to form a structure of a self-injection linearly polarized single-frequency laser. Due to the design of the whole machine, linearly polarized output in an isotropic crystal is realized by a self-injection method, and the linearly polarized and stable single-frequency laser with high power is obtained. The method is complete and accurate, and is applied to injection frequency locking technology study of a single Tm-doped isotropic medium including Tm<3+>:YAG. The application field includes the fields of optoelectronic countermeasure, laser radar, laser medicine and the like.

Owner:CHANGCHUN UNIV OF SCI & TECH

Method for manufacturing piezoelectric resonator

ActiveUS7594307B2Easy to adjustImprove frequency measurement accuracyPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyVibrating electrodeMetal thin film

A method of manufacturing a piezoelectric resonator includes forming first electrodes larger than vibrating electrodes in an area D1 including the vibrating electrodes on obverse and reverse surfaces of a piezoelectric substrate, and measuring the resonant frequency fr1 of a resonator including the first electrodes. The thickness of a metallic thin film required for frequency adjustment is determined based on the measured resonant frequency. Then, second electrodes formed of the metallic thin film having the determined thickness are formed in an area D2 including at least the vibrating electrodes of the piezoelectric substrate. By removing unnecessary portions of the first and second electrodes, a pattern of the resulting vibrating electrodes is formed. Thus, high-accuracy frequency adjustment can be achieved without the need for complicated positioning.

Owner:MURATA MFG CO LTD

Method for electrically contacting a piezoelectric ceramic

ActiveUS20160141488A1Stable and rugged contactingProlong lifePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesTransducerCeramic

A method for electrically contacting a piezoelectric ceramic includes: providing the piezoelectric ceramic having electrodes for electrically contacting the piezoelectric ceramic and having a flexible, electrically conductive film; producing a composite by applying the flexible, electrically conductive film at least partially to an electrode of the piezoelectric ceramic; forming a durable, electrically conductive connection between the flexible, electrically conductive film and the electrode of the piezoelectric ceramic. Also a sound transducer, as well as a sound transducer array produced using the method for electrically contacting a piezoelectric ceramic.

Owner:ROBERT BOSCH GMBH

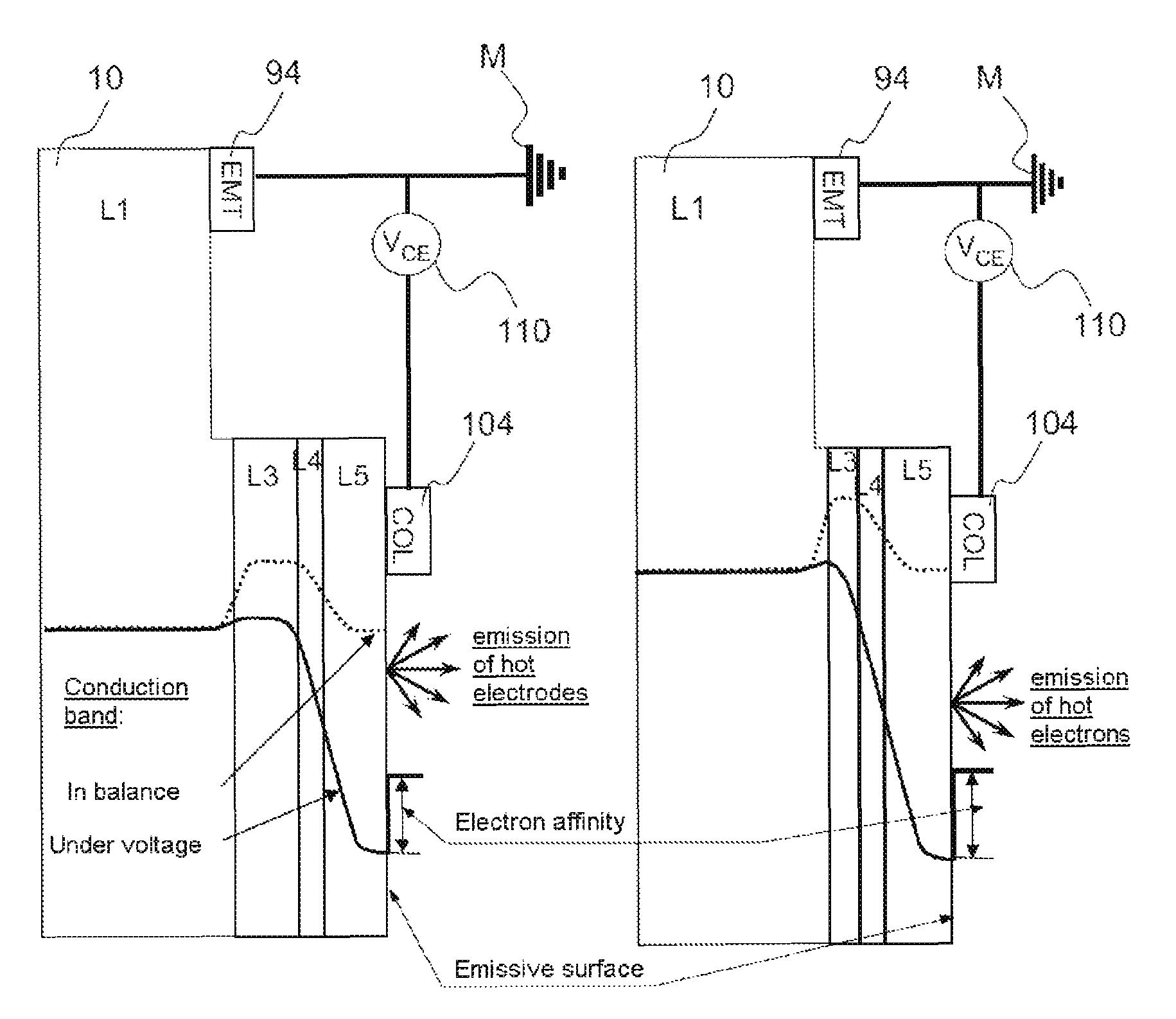

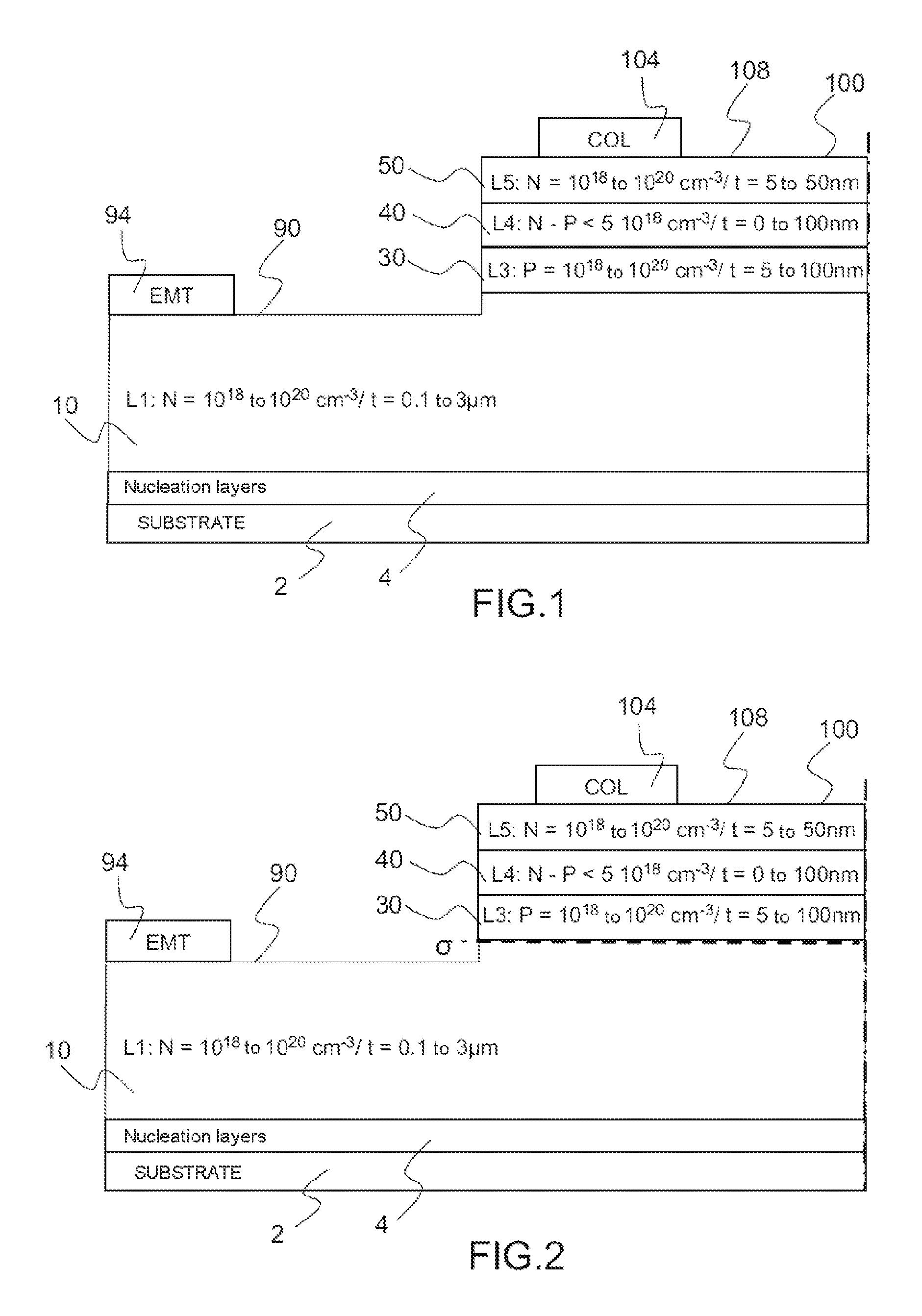

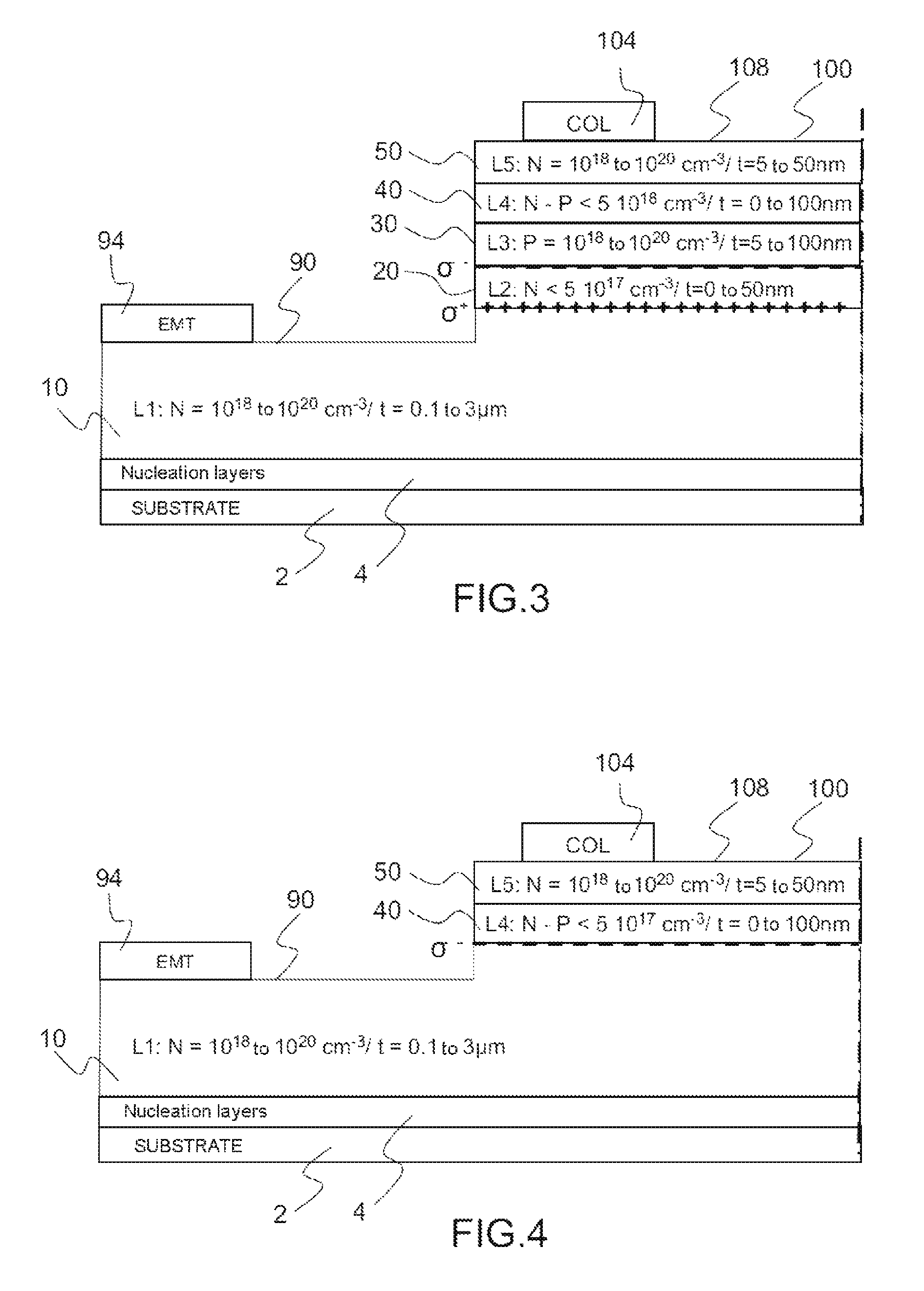

Semiconductor device for electron emission in a vacuum

ActiveUS9305734B2Reduce volumeExtend your lifeTransit-tube cathodesDischarge tube/lamp detailsSemiconductor materialsHigh energy

A semiconductor device for electron emission in a vacuum comprises a stack of two or more semi-conductor layers of N and P type according to sequence N / (P) / N forming a juxtaposition of two head-to-tail NP junctions, in materials belonging to the III-N family, two adjacent layers forming an interface. The semiconductor materials of the layers of the stack close to the vacuum, where the electrons reach a high energy, have a band gap Eg>c / 2, where c is the electron affinity of the semiconductor material, the P-type semiconductor layer being obtained partially or completely, by doping impurities of acceptor type or by piezoelectric effect to exhibit a negative fixed charge in any interface between the layers, a positive bias potential applied to the stack supplying, to a fraction of electrons circulating in the stack, the energy needed for emission in the vacuum by an emissive zone of an output layer.

Owner:THALES SA

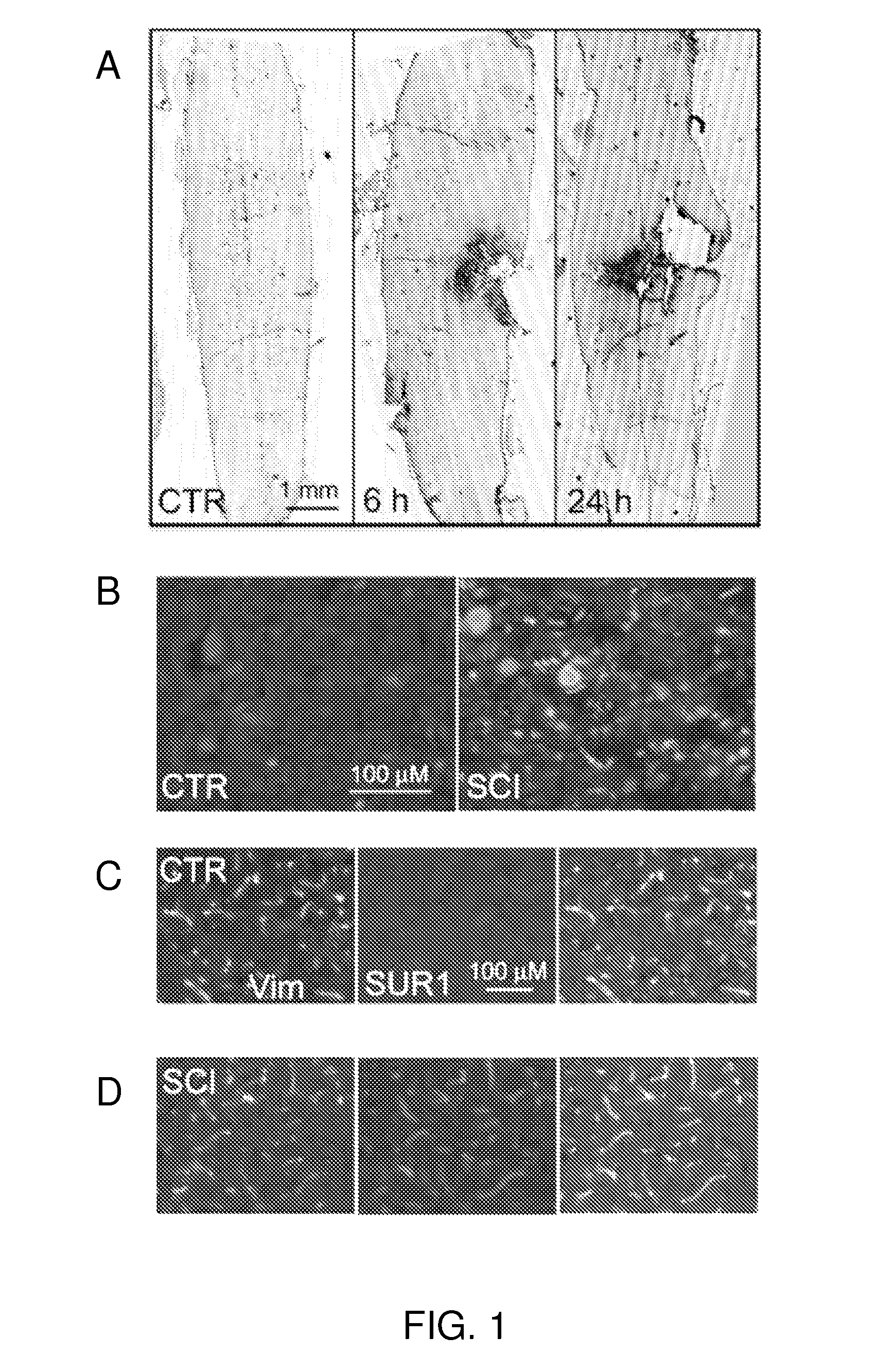

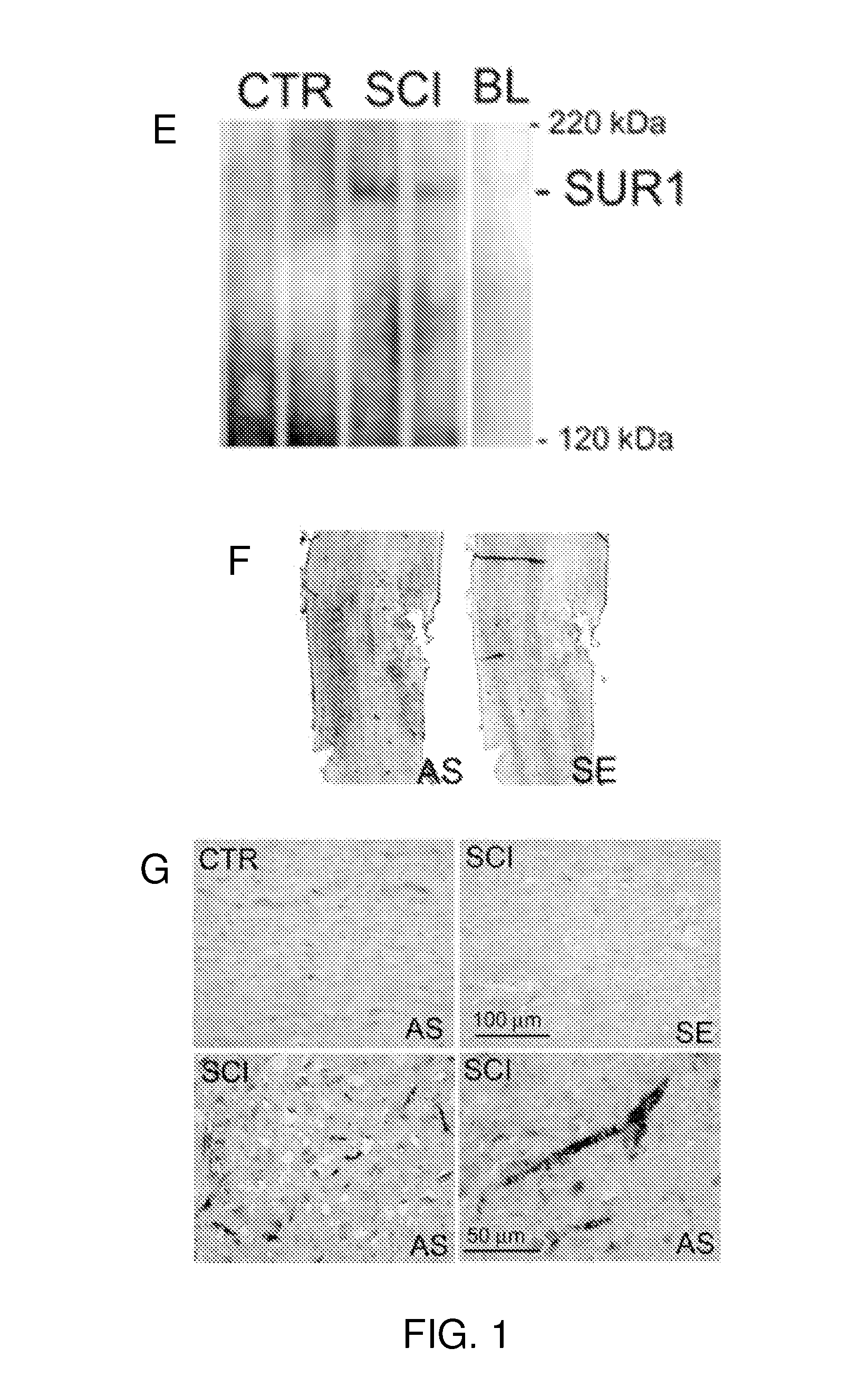

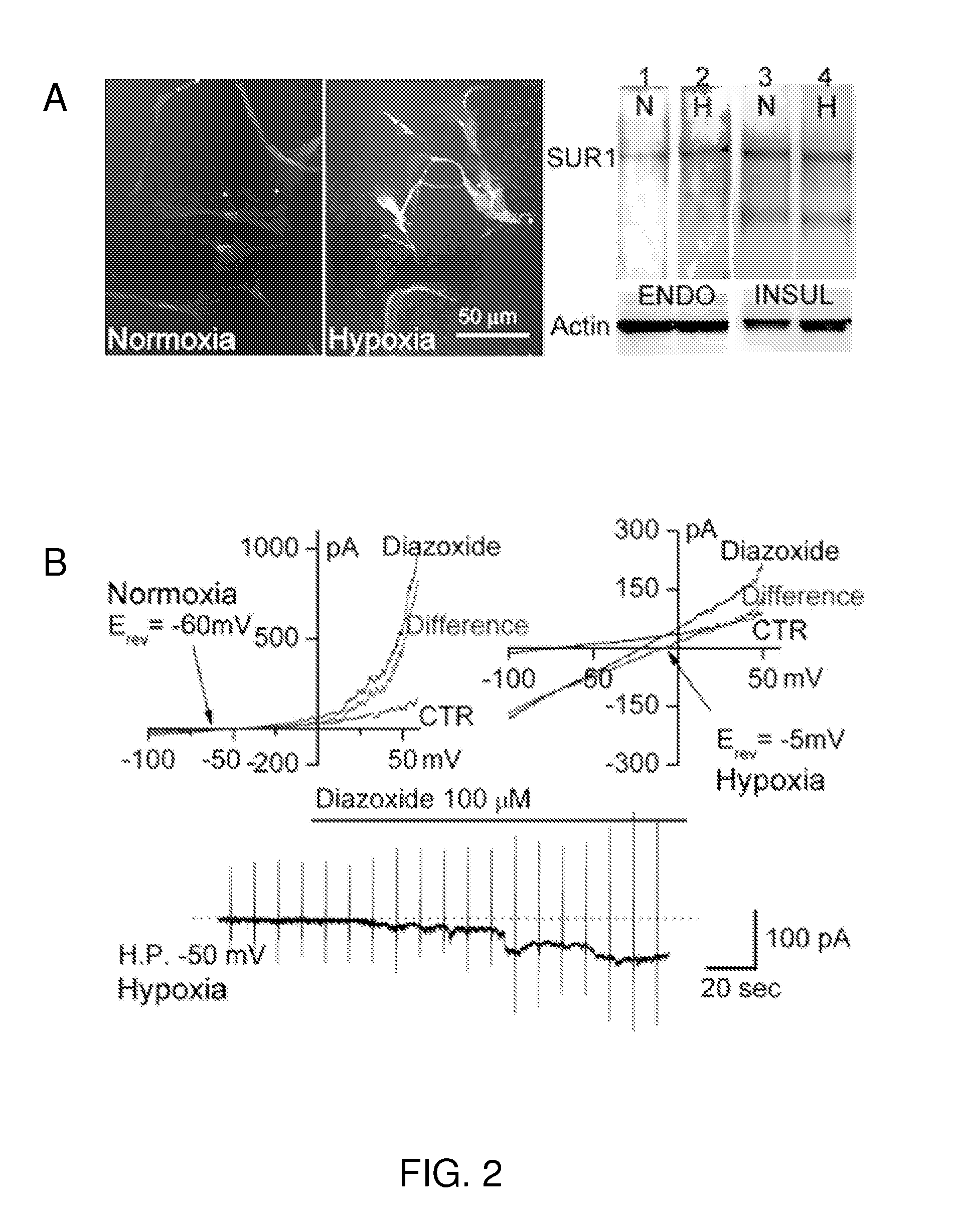

Inhibitors of NCCa-ATP channels for therapy

ActiveUS8557867B2Avoid cell deathPrevent and reduce and depolarizationBiocideNervous disorderHemorrhagic necrosisBrain Cell

Methods and compositions are provided that are utilized for treatment and / or prevention of intraventricular hemorrhage or progressive hemorrhagic necrosis (PHN), particularly following spinal cord injury. In particular, the methods and compositions are inhibitors of a particular NCca-ATP channel and include, for example, inhibitors of SUR1 and / or inhibitors of TRPM4. Kits for treatment and / or prevention of intraventricular hemorrhage or progressive hemorrhagic necrosis (PHN), particularly following spinal cord injury, are also provided. The present invention also concerns treatment and / or prevention of intraventricular hemorrhage in infants, including premature infants utilizing one or more inhibitors of the channel is provided to the infant, for example to brain cells of the infant.

Owner:U S GOVERNMENT REPRESENTED BY THE DEPT OF VETERANS AFFAIRS

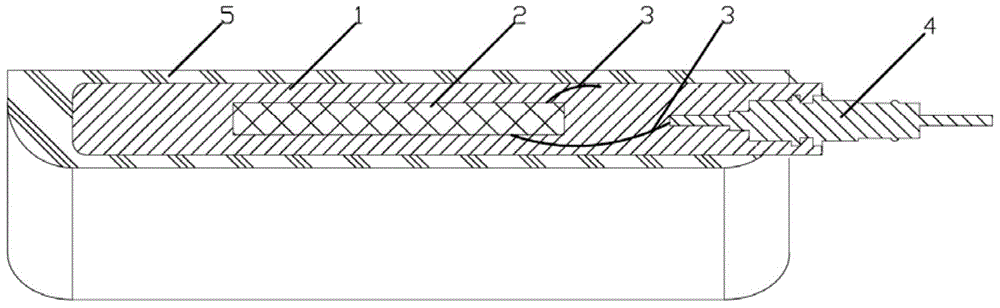

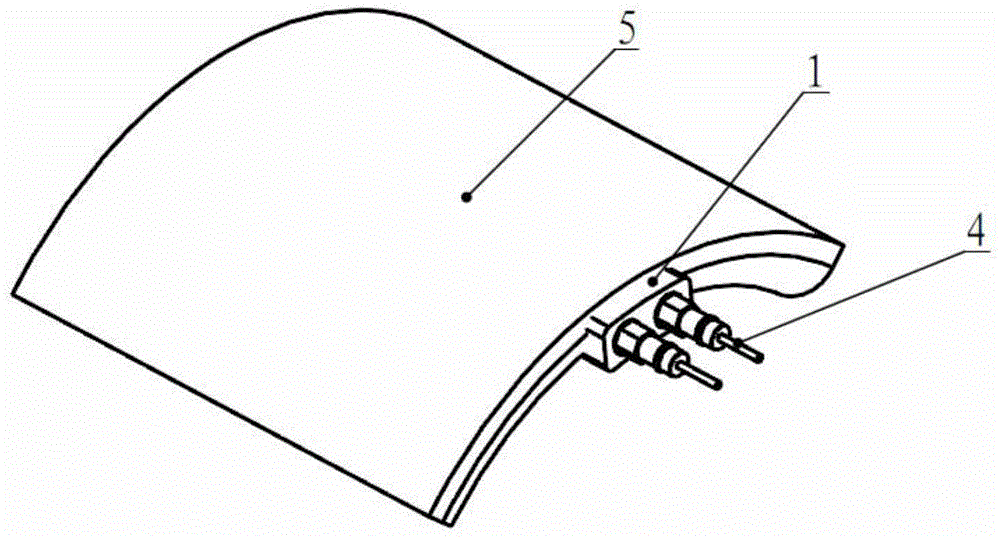

Packaging method for while-drilling acoustic wave transducer

Provided is a packaging method for a while-drilling acoustic wave transducer. The while-drilling acoustic wave transducer comprises a rubber layer, an outer shell, a piezoelectric ceramic crystal and an electric connector, wherein the piezoelectric ceramic crystal and the electric connector are packaged in the outer shell. The packaging method comprises the following steps that (1), an electrode of the piezoelectric ceramic crystal and the electric connector are connected with each other through a lead and placed in a mold; (2), packaging materials are prepared, and the packaging materials are identical with the piezoelectric ceramic crystal in thermal expansion coefficient; (3), the mold is filled with the packaging materials which are heated to the melting point, the outer shell is formed after the packaging materials are cooled and solidified, and the packaging materials, the piezoelectric ceramic crystal and the electric connector are made to be packaged into a whole; and (4), the rubber layer is laid on the outer side of the outer shell. By means of the packaging method, it is guaranteed that the piezoelectric ceramic crystal in the transducer cannot be damaged in the packaging process, the rubber layer is laid on the outer side of the outer shell of the while-drilling acoustic wave transducer so as to resist vibration, and installation of the transducer is facilitated.

Owner:CHINA NAT OFFSHORE OIL CORP +1

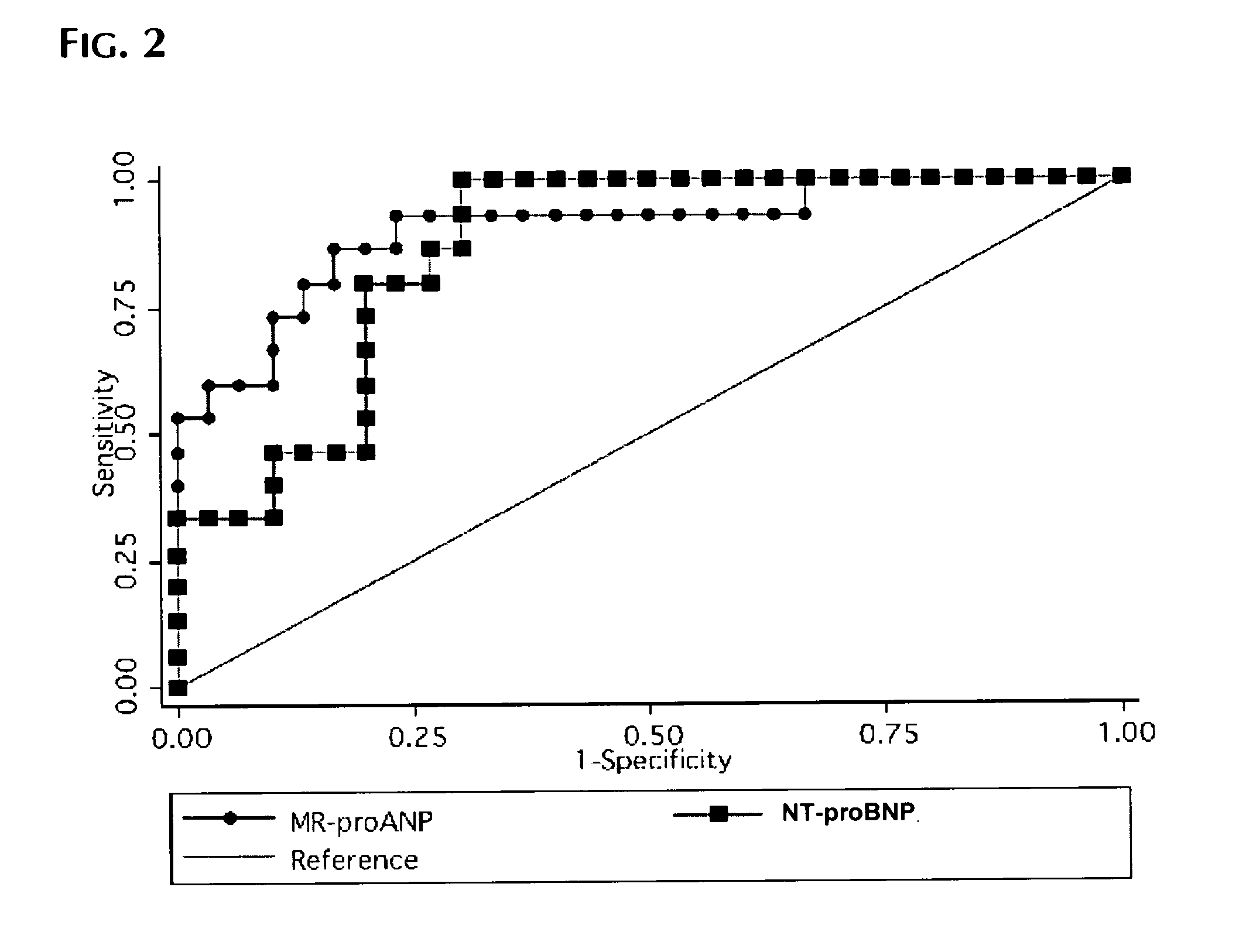

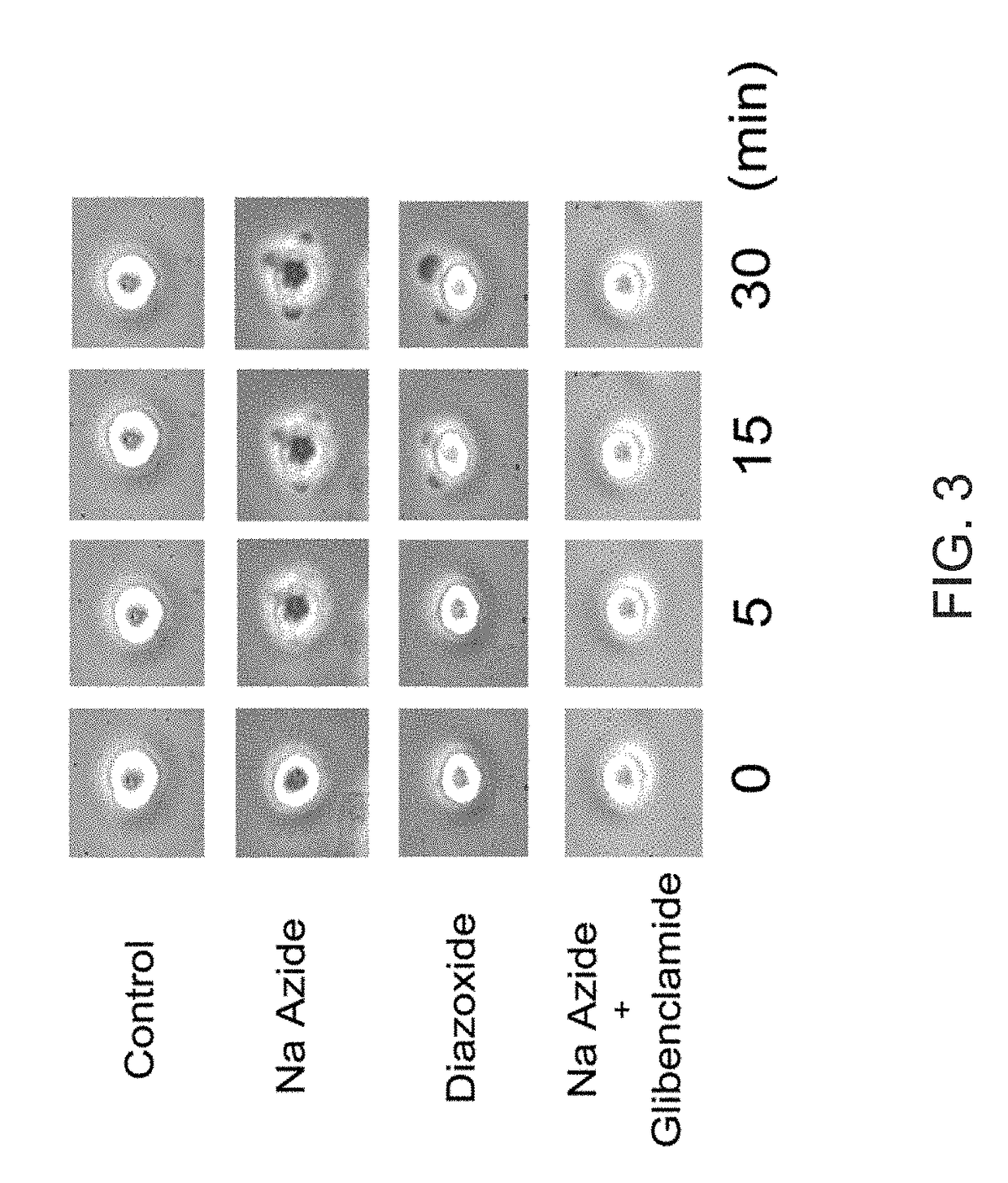

Targeting NCCA-ATP channel for organ protection following ischemic episode

ActiveUS9511075B2Avoid damageAvoid depolarizationBiocidePeptide/protein ingredientsReperfusion injuryAngina

The present invention concerns protection of an organ or tissue following an ischemic episode In particular aspects, the invention concerns organ preservation for transplantation, angina pectoris, kidney reperfusion injury, and so forth In specific embodiments, the organ is subjected to an inhibitor of an NCCa-ATP channel that is regulated by SUR1 Exemplary inhibitors include sulfonylurea compounds, such as glibenclamide, for example.

Owner:U S GOVERNMENT REPRESENTED BY THE DEPT OF VETERANS AFFAIRS

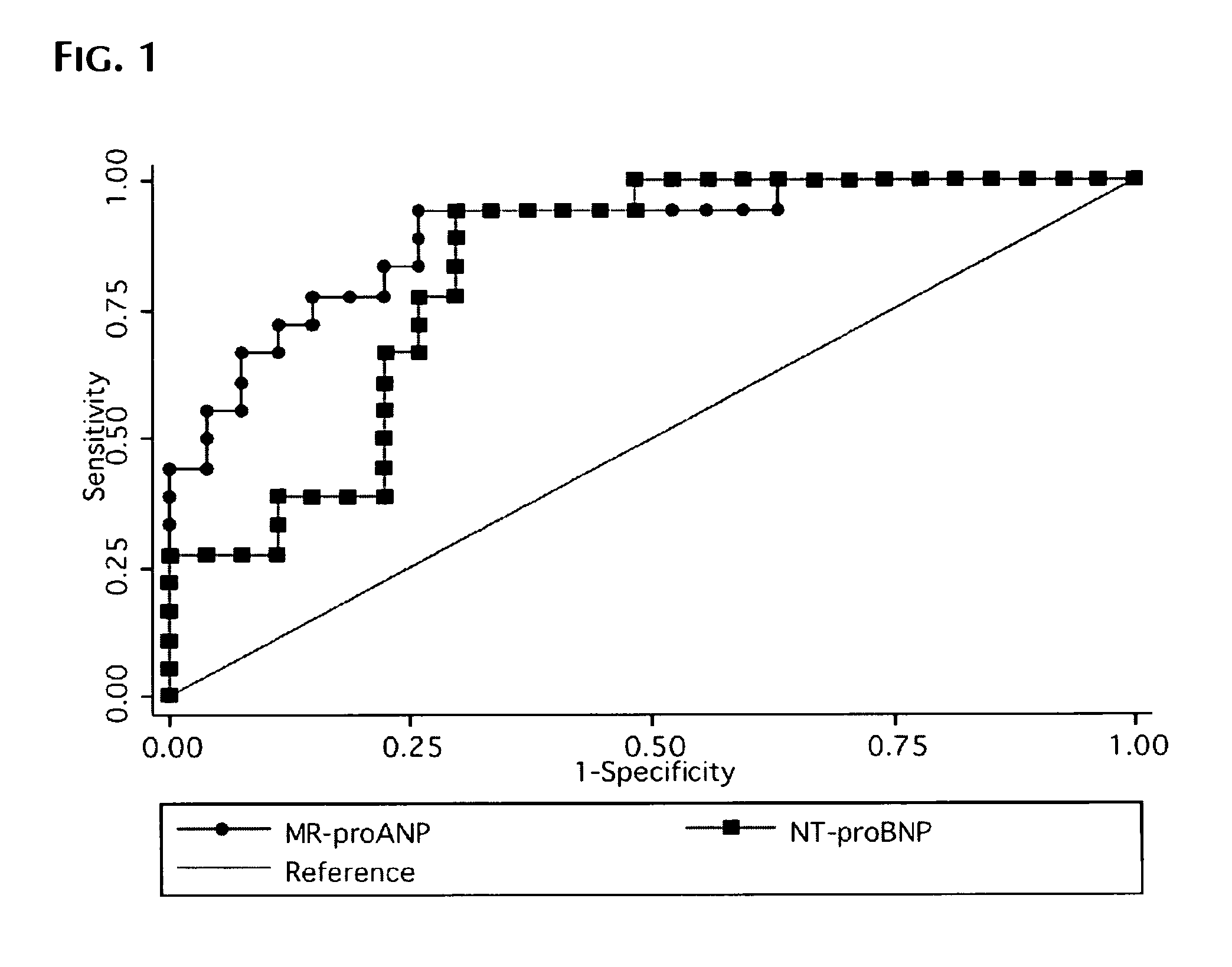

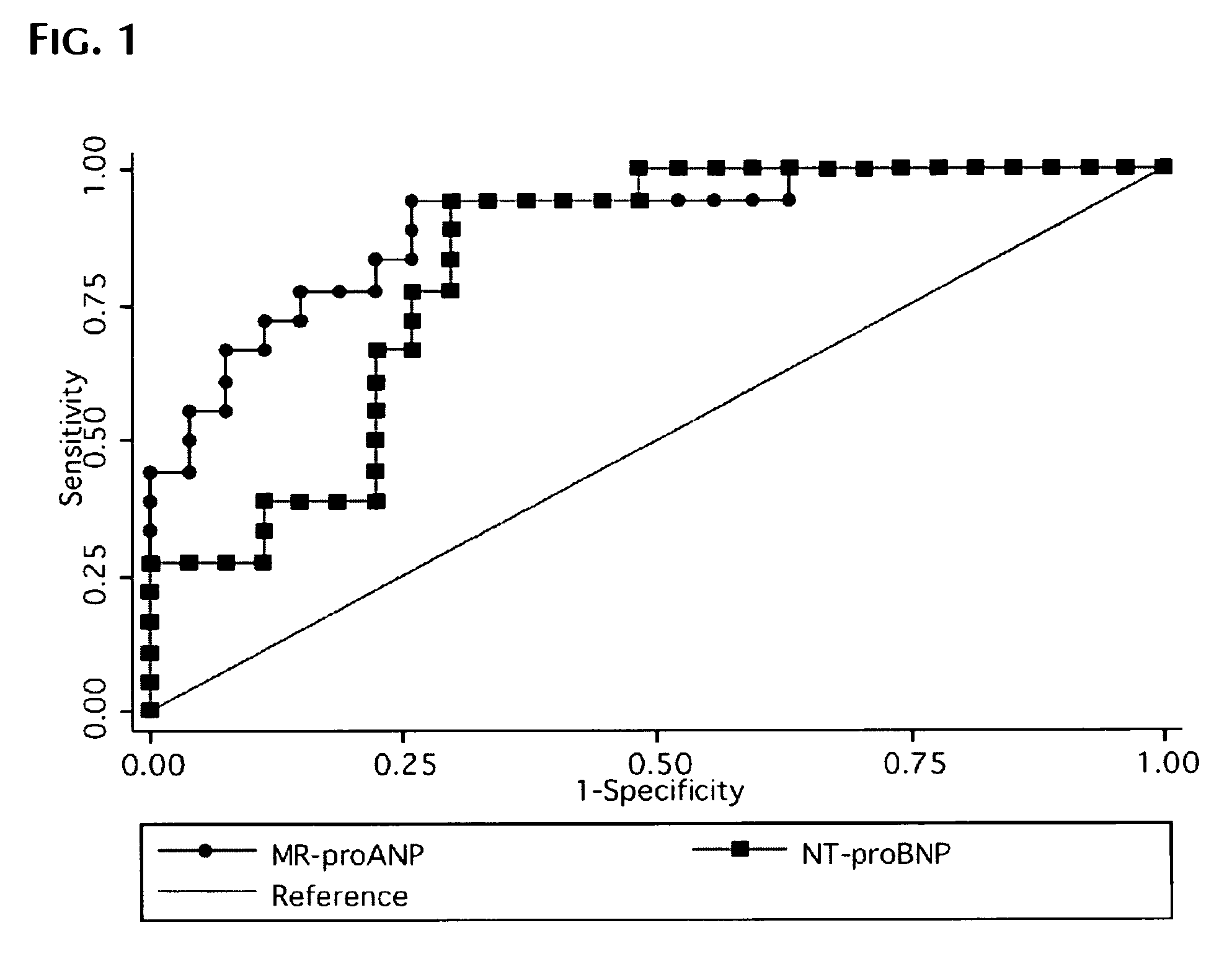

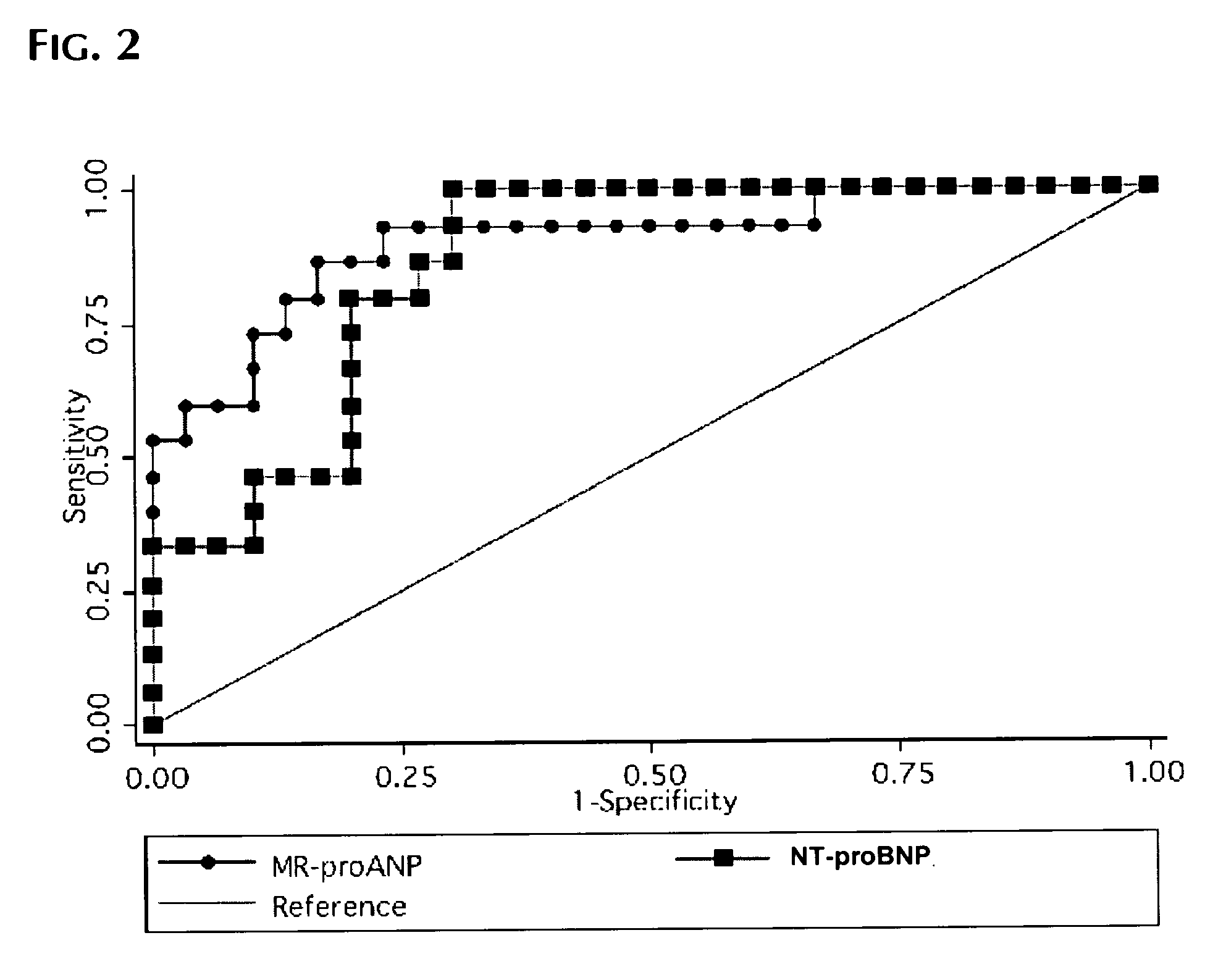

Mid-regional pro-atrial natriuretic peptide (pro-anp) for the identification of patients with atrial fibrillation with an onset of less than 48 hours ago

ActiveUS20140170771A1Increase opportunitiesSlows phase depolarizationDisease diagnosisBiological testingANP - Atrial natriuretic peptideAtrial natriuretic peptide

The invention relates to a method for the determination of the time from onset of atrial fibrillation to presentation in a patient comprising the steps of: providing a sample of a bodily fluid of said patient, determining the level of proANP (SEQ ID NO: 1) or fragments thereof in said sample, correlating the level of proANP or fragments thereof to the time from the onset of atrial fibrillation to presentation of said patient, wherein said fragments have a length of at least 6 amino acid residues.

Owner:BRAHMS GMBH +2

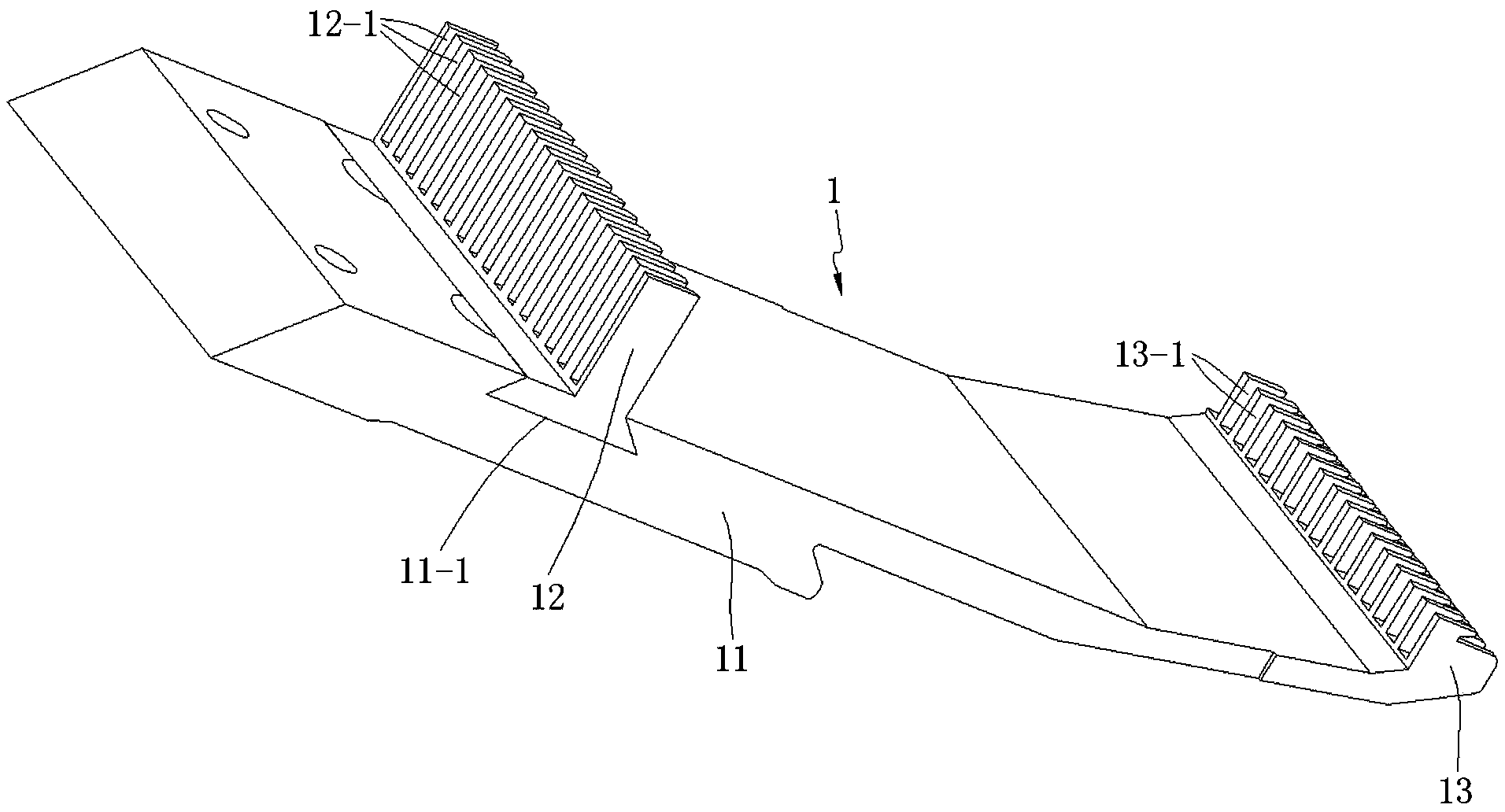

Stepped piezoelectric energy collector based on laser surface thinning and preparation method

InactiveCN113315415AIncrease energy densityAvoid depolarizationPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamHigh energy

The invention relates to a stepped piezoelectric energy collector based on laser surface thinning and a preparation method, the stepped piezoelectric energy collector comprises a cantilever beam, and a fixing device and a mass block which are arranged at two ends of the cantilever beam, the cantilever beam comprises a piezoelectric layer, a bonding layer and a metal substrate layer which are sequentially arranged from top to bottom, and the thicknesses of the piezoelectric layer and the metal substrate layer are gradually reduced in a stepped manner along the length direction of the cantilever beam pointing to the mass block. Compared with the prior art, the stepped thinning process is carried out through laser equipment, stress is released on a traditional rectangular cantilever beam, the low-frequency, high-output and high-energy-density stepped piezoelectric energy collection device is obtained, and the piezoelectric energy collection device has the advantages of being simple in preparation method, high in controllability, good in compatibility and the like; and the prepared stepped cantilever beam has the advantages of high energy density, low resonant frequency, high output electric energy and the like, and has a relatively wide application prospect.

Owner:SHANGHAI INST OF TECH

Methods for antagonists of a non-selective cation channel in neural cells

InactiveUS20190111137A1Avoid depolarizationReduce and preventOrganic active ingredientsNervous disorderDiseaseNervous system

The present invention is directed to a combination of therapeutic compounds and treatment methods and kits using the combination. In particular, one of the combination affects the NCCa-ATP channel of neural tissue, including neurons, glia and blood vessels within the nervous system. Exemplary SUR1 and / or TRPM4 antagonists that inhibit the NCCa-ATP channel may be employed in the combination. The combination therapy also employs one or more of a non-selective cation channel blocker and / or an antagonist of VEFG, NOS, MMP, or thrombin. Exemplary indications for the combination therapy includes the prevention, diminution, and / or treatment of injured or diseased neural tissue, including astrocytes, neurons and capillary endothelial cells, that is due to ischemia, tissue trauma, brain swelling and increased tissue pressure, or other forms of brain or spinal cord disease or injury, for example. In other embodiments, there are methods and compositions directed to antagonists of TRPM4, including at least for therapeutic treatment of traumatic brain injury, cerebral ischemia, central nervous system (CNS) damage, peripheral nervous system (PNS) damage, cerebral hypoxia, or edema, for example.

Owner:U S GOVERNMENT REPRESENTED BY THE DEPT OF VETERANS AFFAIRS

Targeting ncca-atp channel for organ protection following ischemic episode

ActiveUS20170296555A1Avoid damageAvoid depolarizationOrganic active ingredientsPeptide/protein ingredientsNervous systemReperfusion injury

The present invention concerns protection of an organ or tissue outside of the central nervous system following an ischemic episode. In particular aspects, the invention concerns organ preservation for transplantation, angina pectoris, kidney reperfusion injury, and so forth. In specific embodiments, the organ is subjected to an inhibitor of an NCCa-ATP channel that is regulated by SUR1. Exemplary inhibitors include sulfonylurea compounds, such as glibenclamide, for example.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE DEPT OF VETERANS AFFAIRS

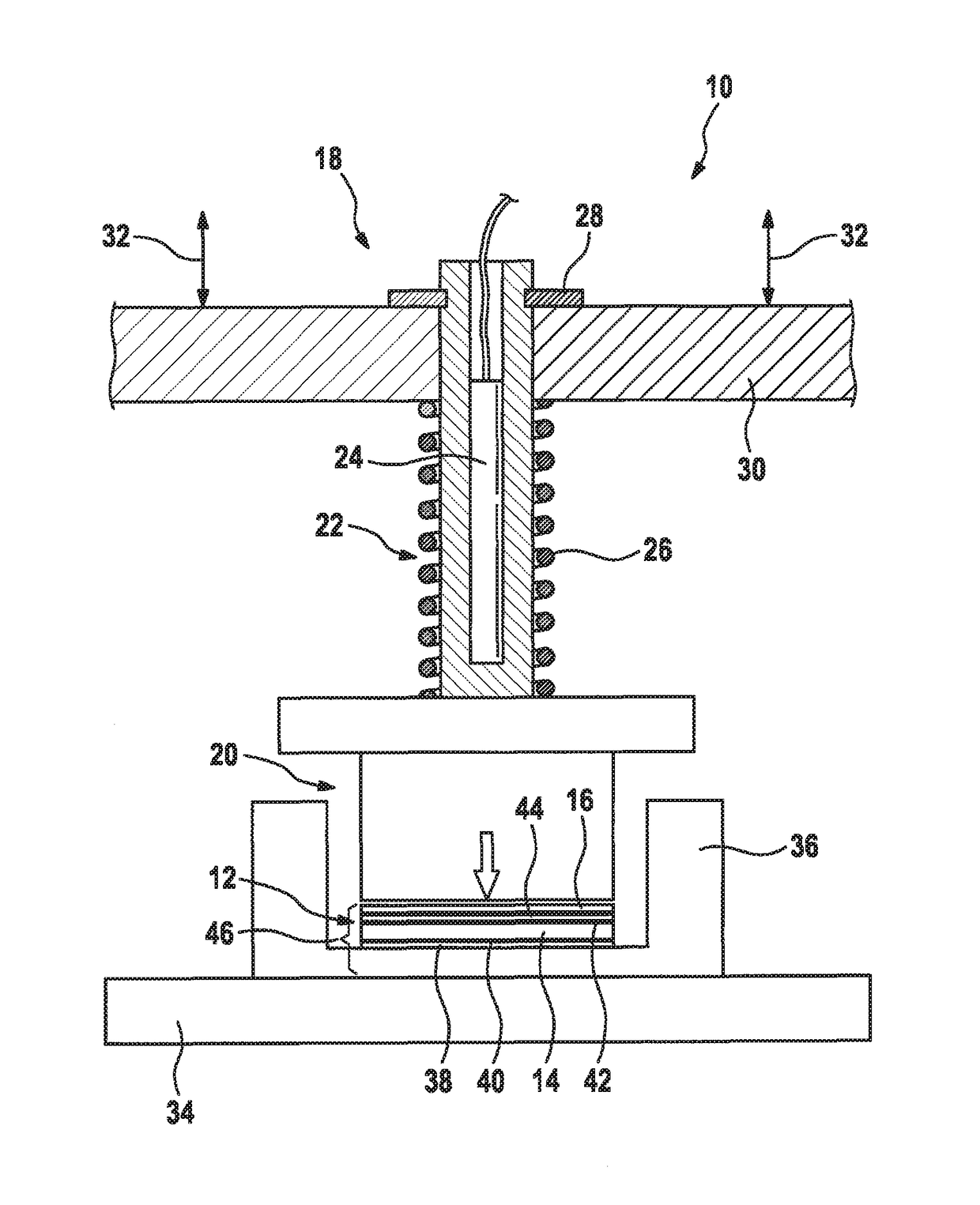

Rest assembly for recovering the geoelectric field

InactiveUS20200268164A1Improve posturePrevent degenerative diseaseStuffed mattressesSpring mattressesFiberNatural resin

REST ASSEMBLY FOR RECOVERING THE GEOELECTRIC FIELD, formed from: a laminate, steamed beech wood mattress base (2) with a 100% natural water-based varnish;and a mattress (3) with a core (4) of latex made from a 100% natural emulsion of the resin of the Hevea brasiliensis tree, which latex is whipped and baked at 120 degrees without chemical additives. The mattress comprises: an anti-moisture ionising sheet (5) made of 100% natural steamed and pressed coconut fibre, with a central layer (6) of rocks of pink salt and white quartz; an antibacterial mesh (7) of bamboo fibre; and a cover (8) of fabric comprising 70% cashmere and 30% organic cotton, with a filling of 4 cm disposed on at least the upper part of the mattress and comprising 100% natural wool, a fabric of organic graphite and silver, and an aluminium plate (9) connected to an earthing device (10).

Owner:JIMENEZ CASTILLO ROSA

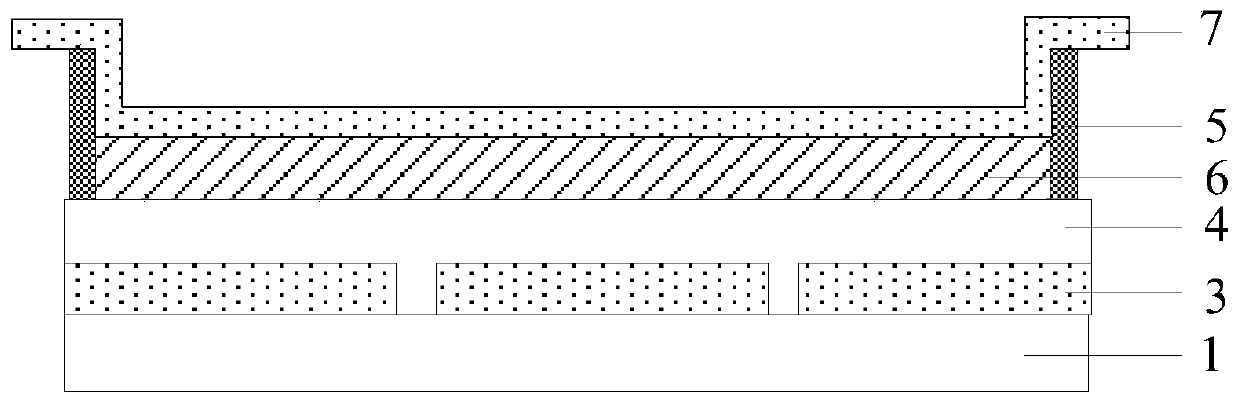

Fingerprint identification module, display device and manufacturing method thereof

ActiveCN110765968AAvoid depolarizationAvoid affecting the bonding processPrint image acquisitionMatching and classificationDisplay deviceEngineering

The invention discloses a fingerprint identification module, a display device and a manufacturing method of the fingerprint identification module, and aims to solve the problems of complex manufacturing process, easiness in depolarization of a piezoelectric film layer, irregular patterns and influence on binding of a subsequent binding area when the piezoelectric film layer is formed in the priorart. A grain recognition module comprises a plurality of first electrodes, piezoelectric parts and second electrodes which are sequentially located on one face of a substrate, wherein the first electrodes, the piezoelectric parts and the second electrodes are arranged in an array mode. The edge area between the layer where the first electrode is located and the layer where the second electrode islocated is further provided with a retaining wall surrounding the piezoelectric part.

Owner:BOE TECH GRP CO LTD

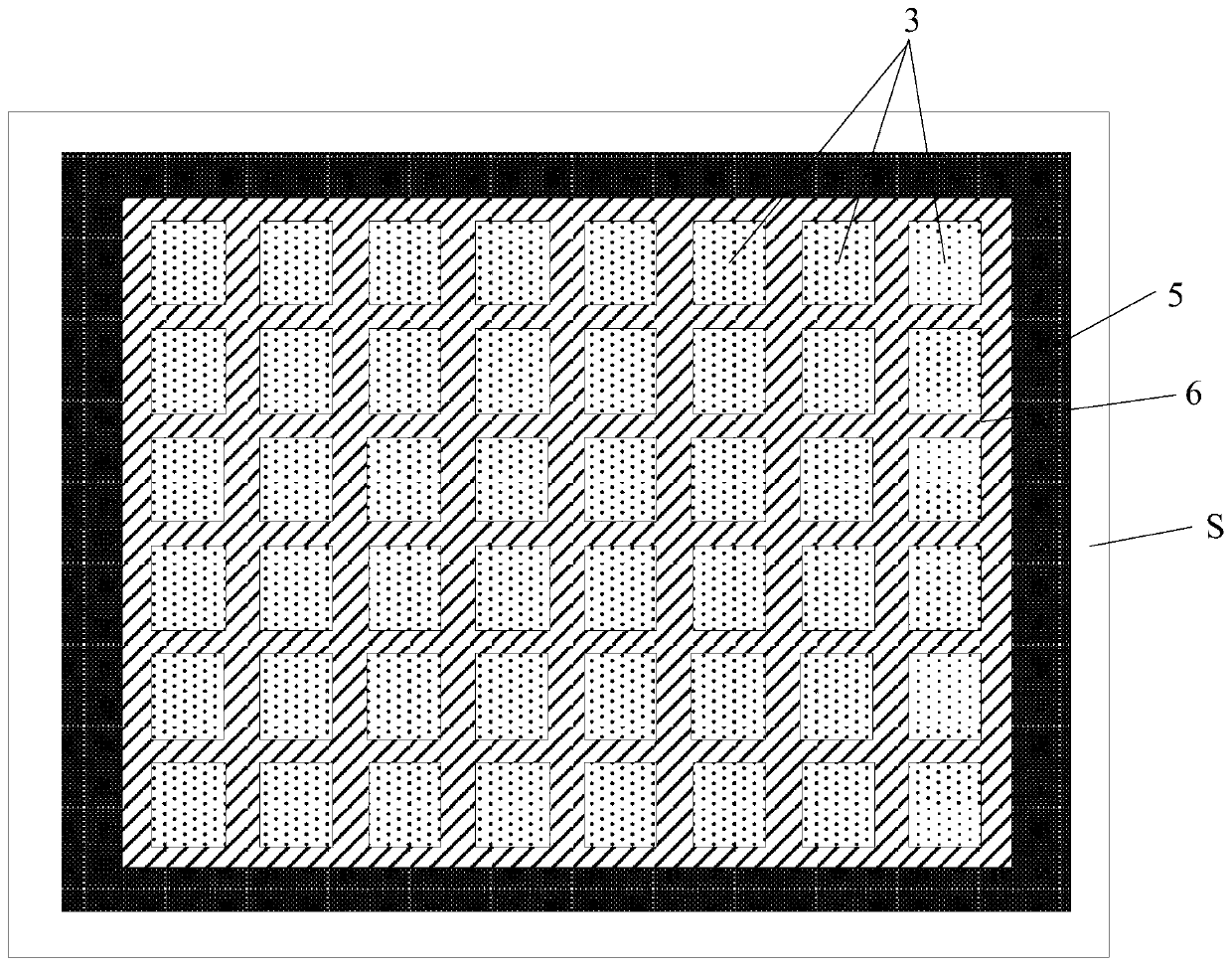

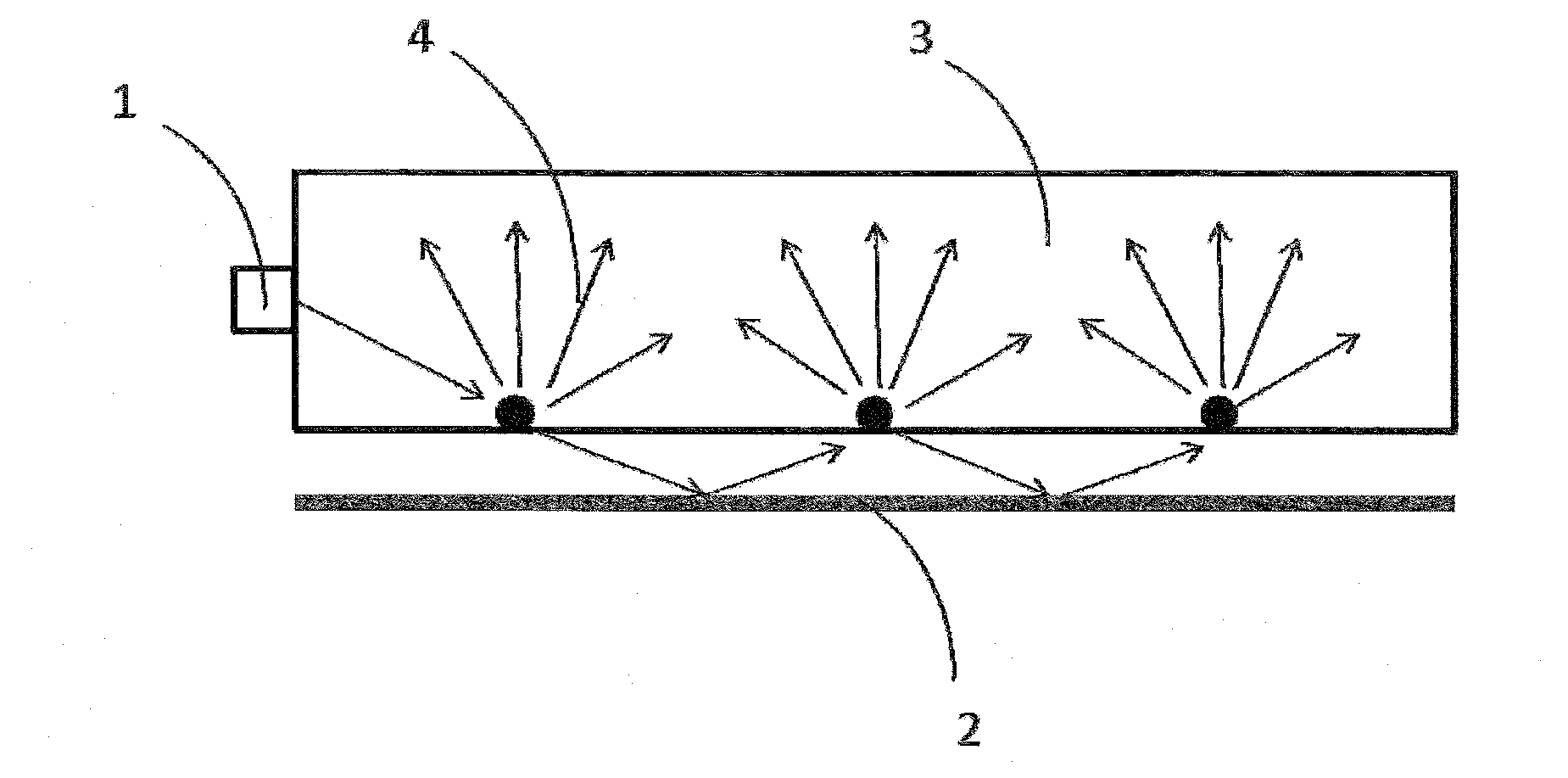

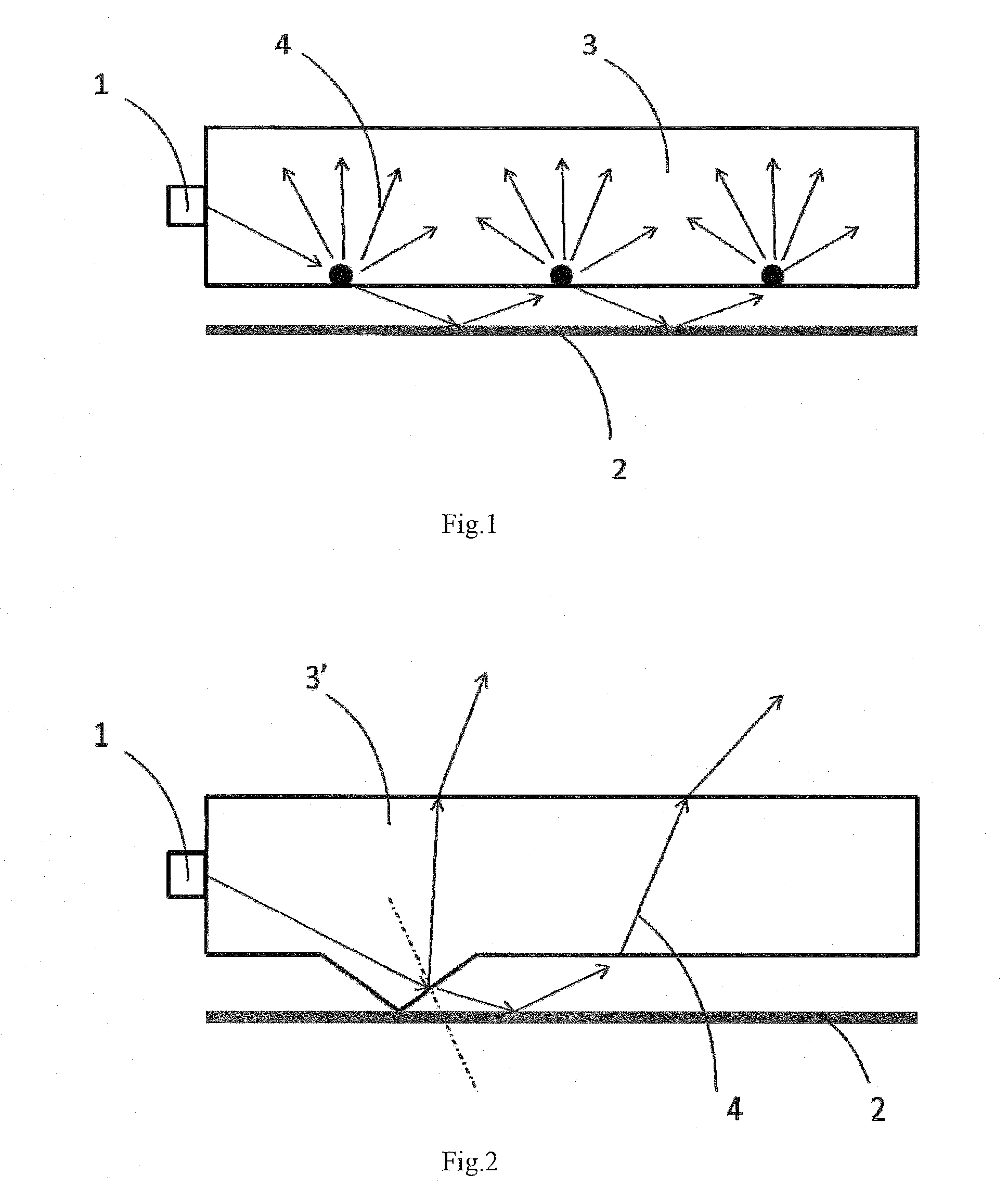

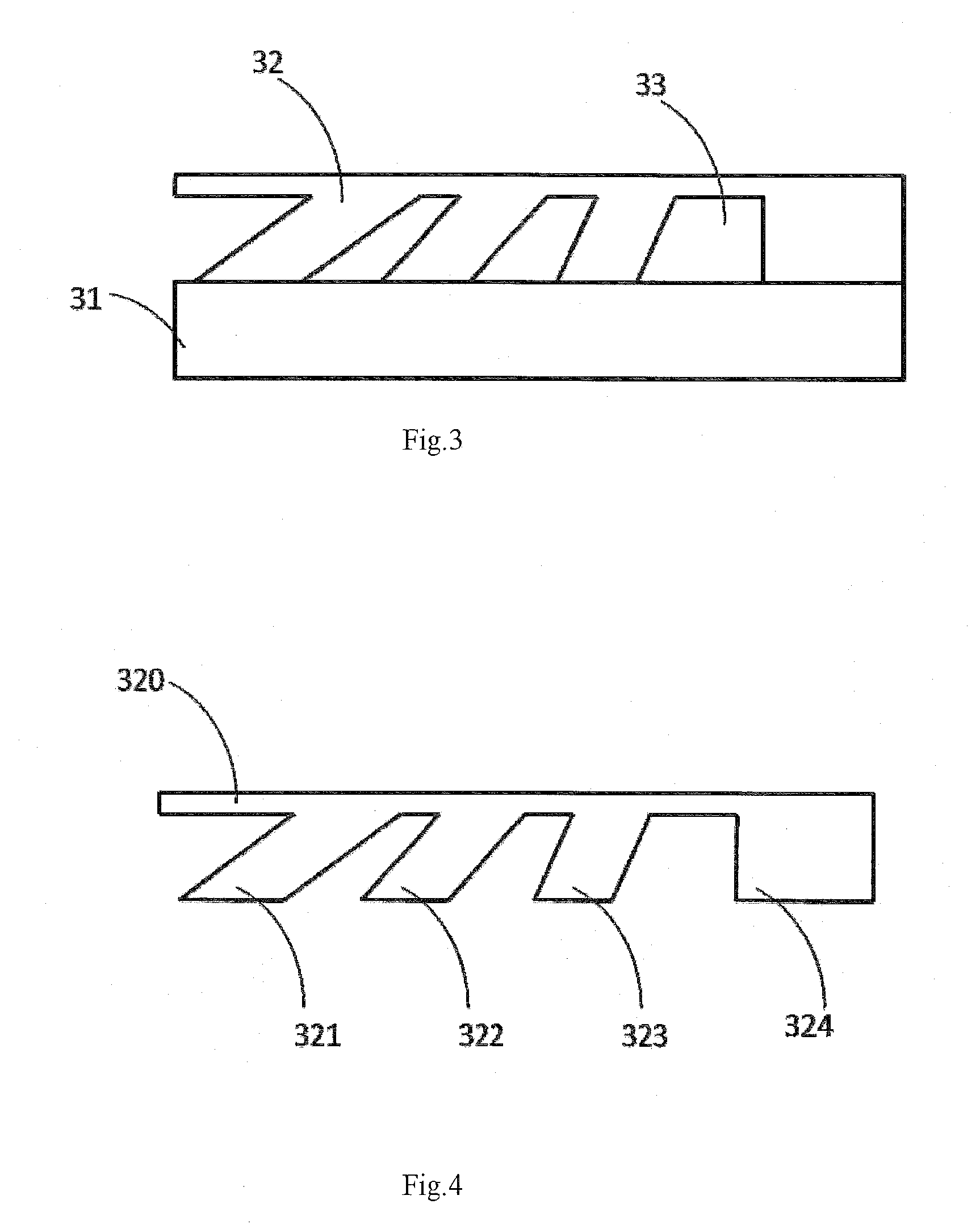

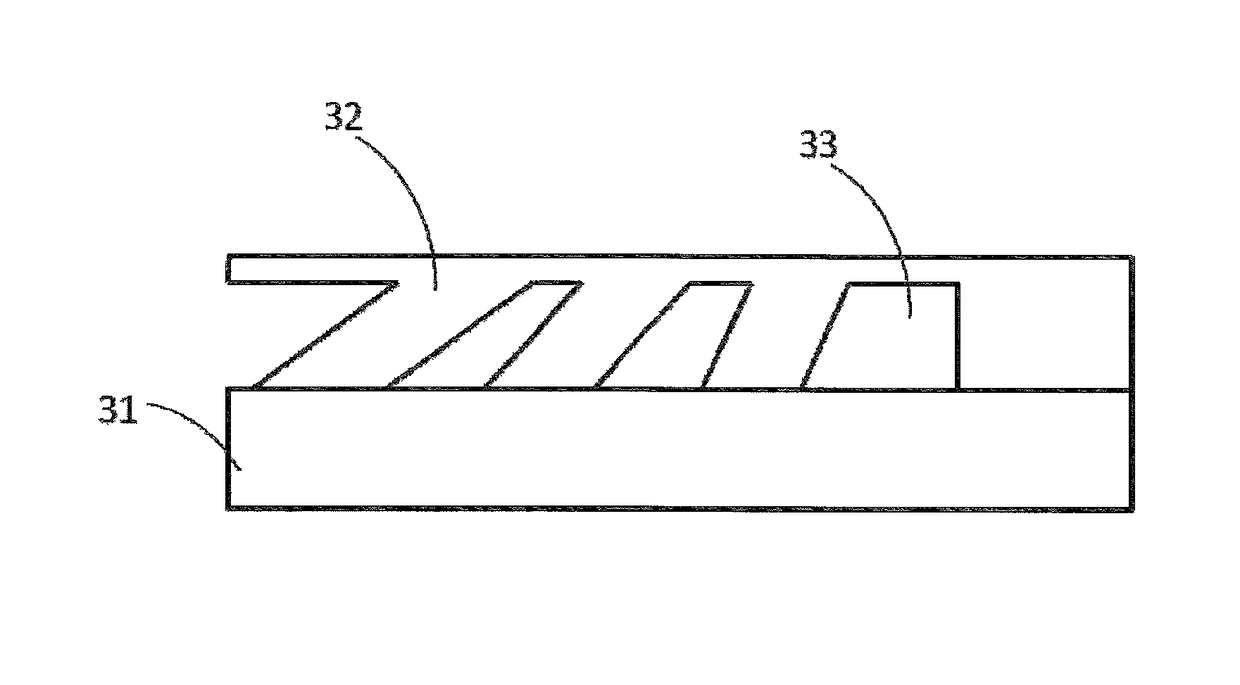

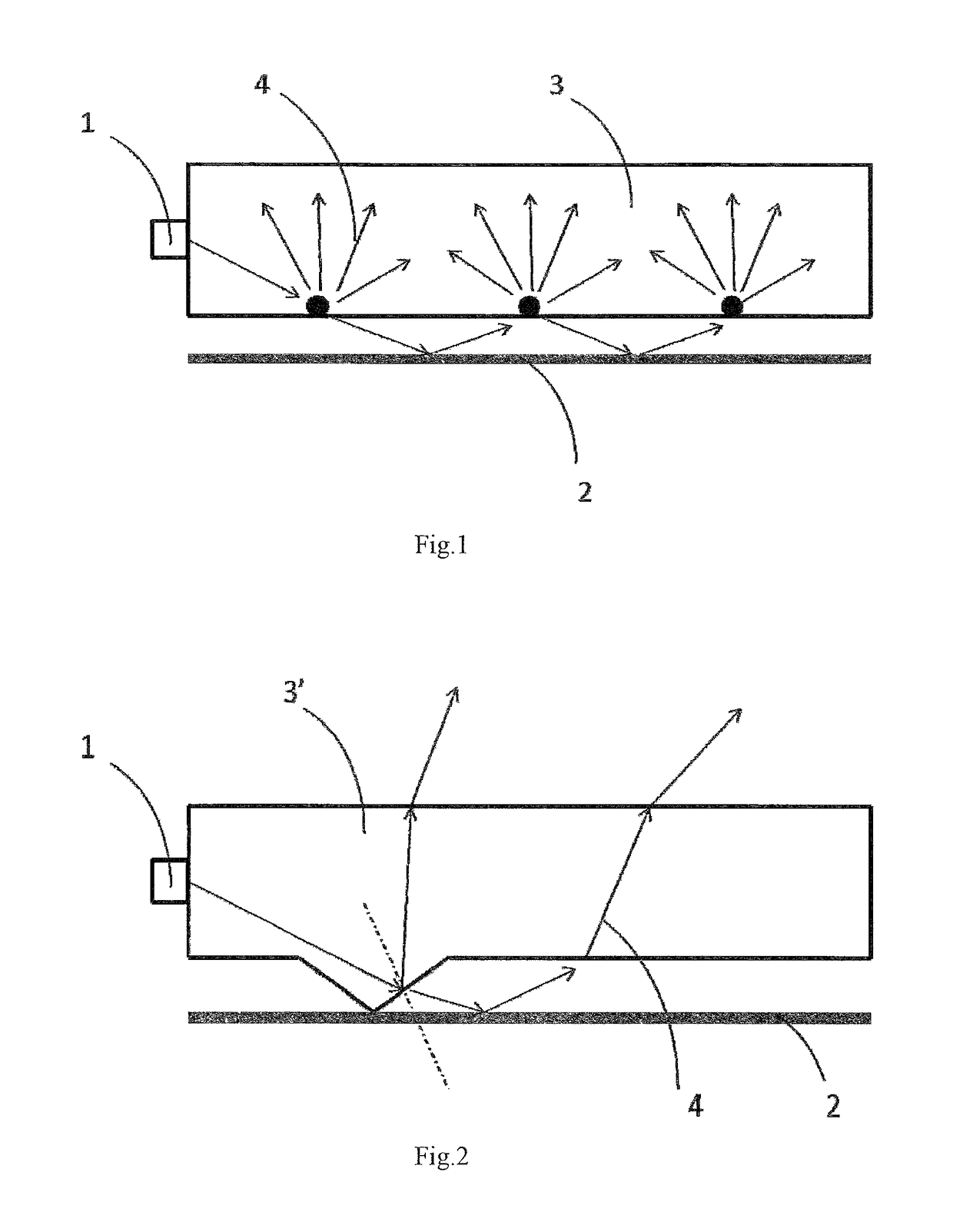

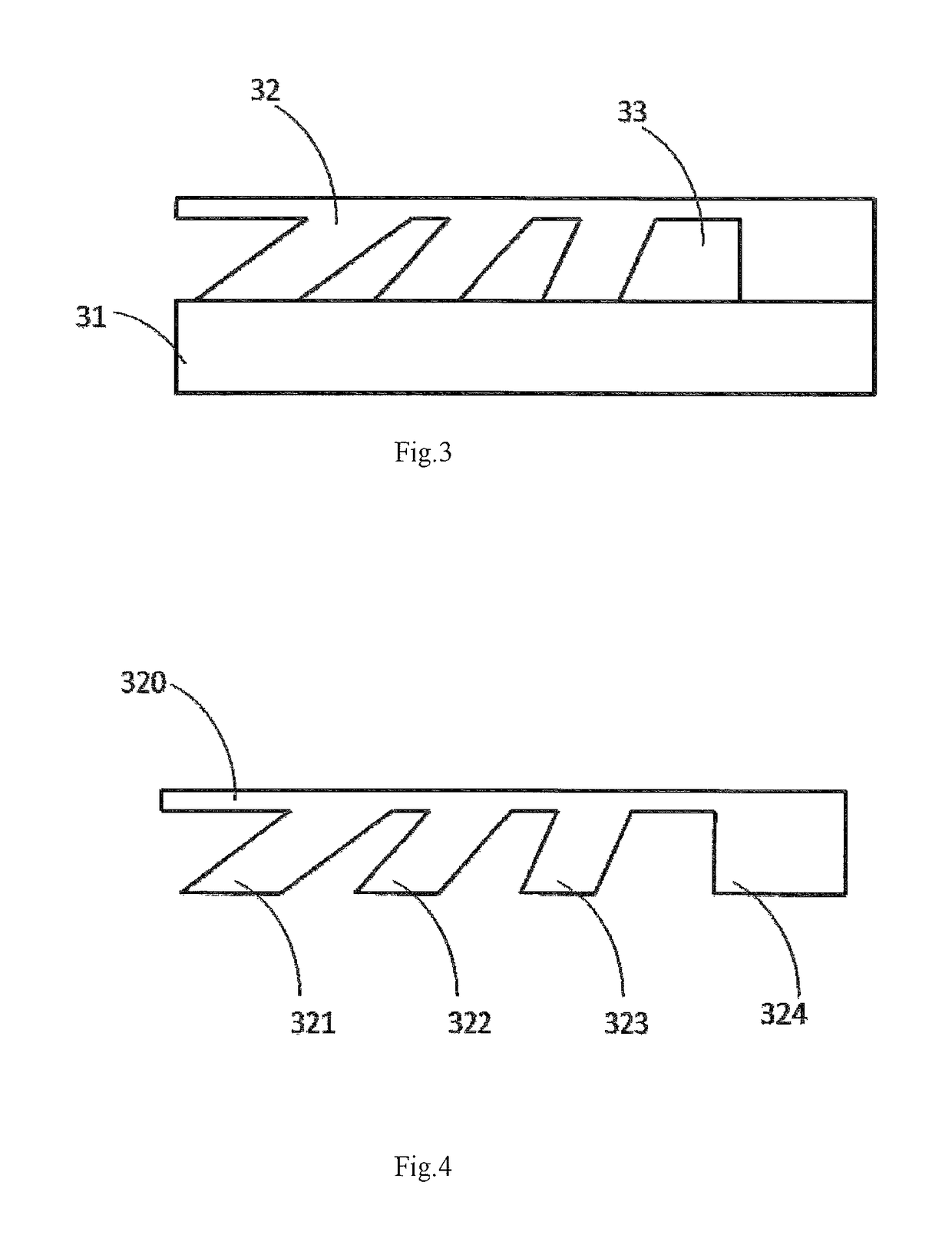

Light guide plate assembly and display apparatus

ActiveUS20170045670A1Uniformity of backlight illuminationUtilization ratio of lightMechanical apparatusLight guides for lighting systemsLight guidePrism

Embodiments of the present invention disclose a light guide plate assembly. The light guide plate assembly includes a light guide plate and an optical coupling member attached to the light guide plate. The optical coupling member includes a plate-like part and a plurality of prism parts formed on the plate-like part. Each of the plurality of prism parts has a planar top surface, the top surface engaging with a light exiting surface of the light guide plate, and each of the plurality of prism parts has a reflective side surface which is configured to reflect incident light towards a light exiting surface of the optical coupling member through total reflection. The present disclosure further discloses a display apparatus including the said light guide plate assembly.

Owner:BOE TECH GRP CO LTD

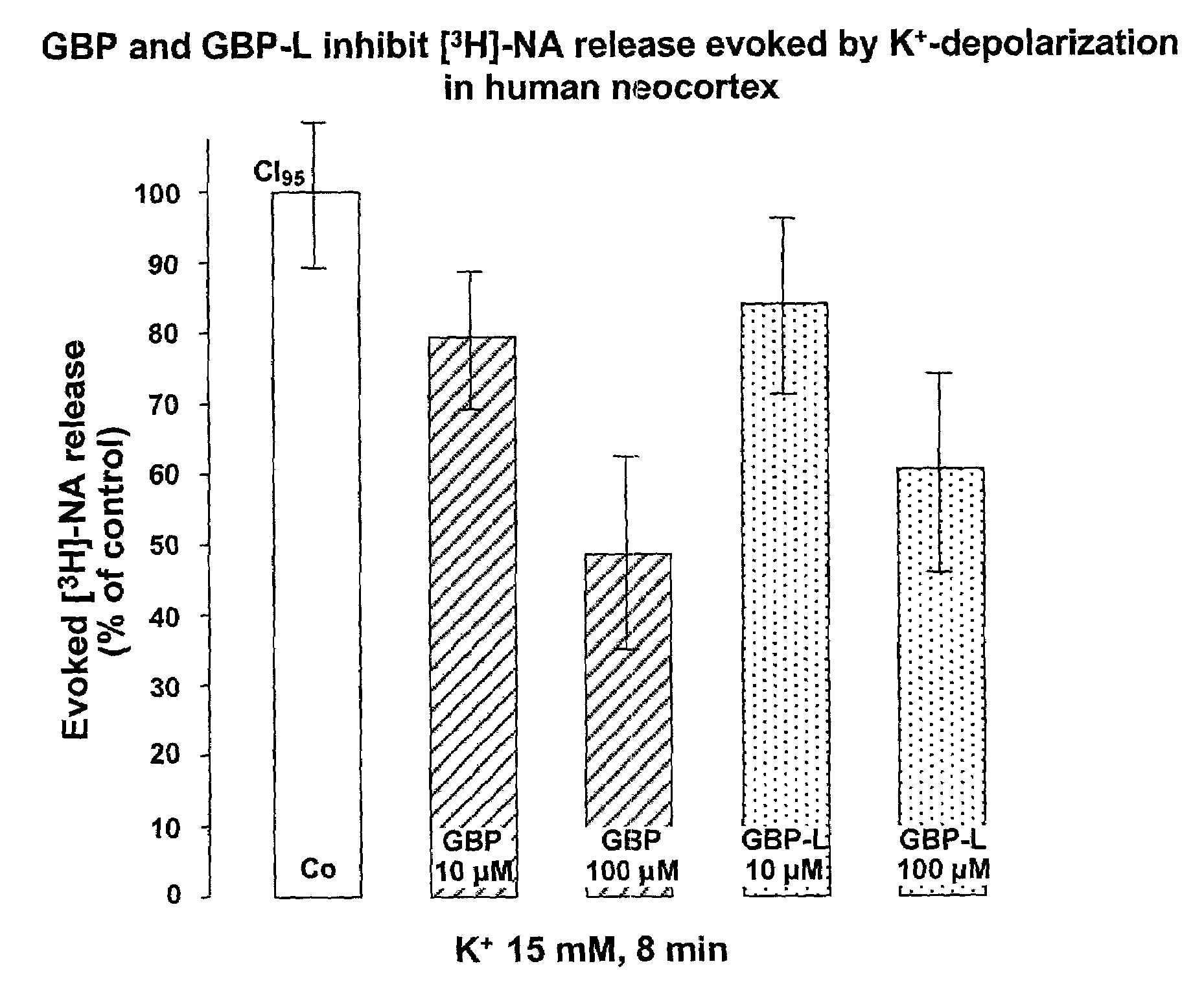

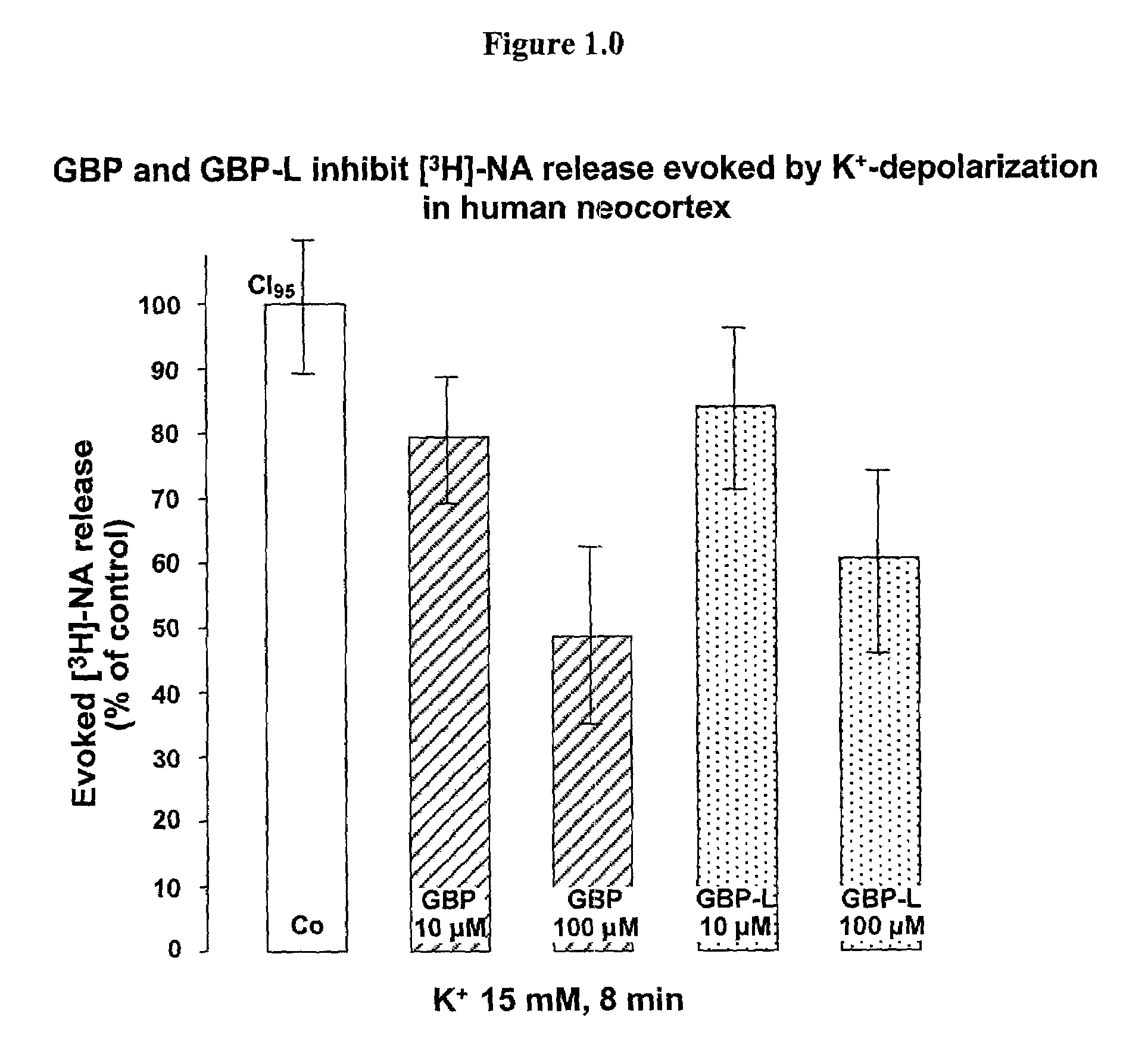

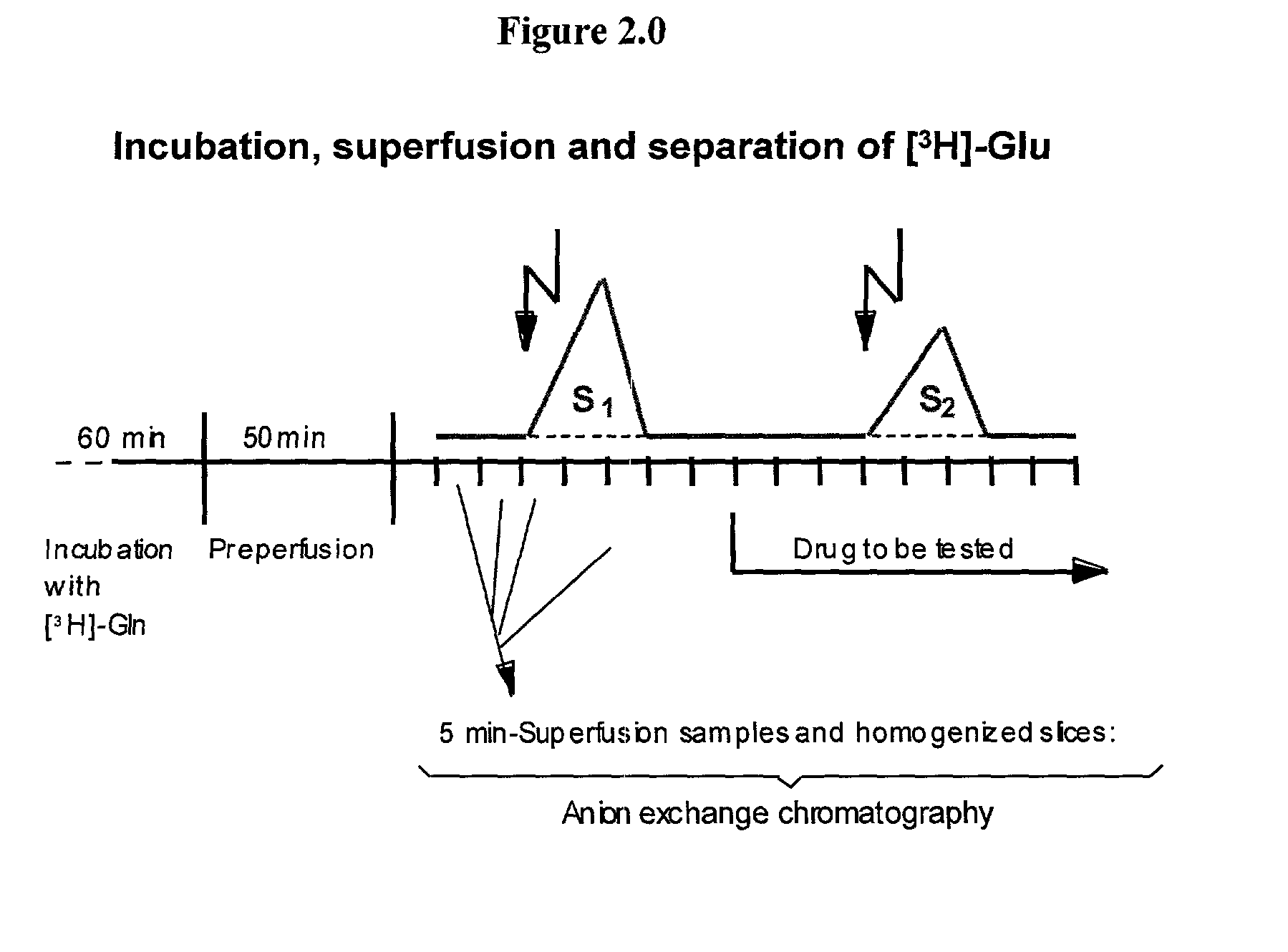

2-pyrrolidinone derivatives substituted at position 4 for reducing the extracellular glutamate level

InactiveUS6984659B2Influence glutamatergic transmissionAvoid depolarizationBiocideAnimal repellantsAtrophyHuntingtons chorea

2-pyrrolidinone derivatives which have in position 4 at least one substituent are described herein. Methods of treating polygltamine disorders such as Huntington's disease, dentorubropallidoluysian atrophy (DRPLA), spinal and bulbar muscular atrophy (SBMA), and spinocerebellar ataxias with 2-pyrrolidinone derivatives are also descibed.

Owner:KLINIKUM DER ALBERT LUDWIGS UNIV FREIBURG

Light guide plate assembly and display apparatus

ActiveUS10126483B2Utilization ratio of lightIncrease display brightnessMechanical apparatusLight guides for lighting systemsLight guideLight reflection

Embodiments of the present invention disclose a light guide plate assembly. The light guide plate assembly includes a light guide plate and an optical coupling member attached to the light guide plate. The optical coupling member includes a plate-like part and a plurality of prism parts formed on the plate-like part. Each of the plurality of prism parts has a planar top surface, the top surface engaging with a light exiting surface of the light guide plate, and each of the plurality of prism parts has a reflective side surface which is configured to reflect incident light towards a light exiting surface of the optical coupling member through total reflection. The present disclosure further discloses a display apparatus including the said light guide plate assembly.

Owner:BOE TECH GRP CO LTD

Mid-regional pro-atrial natriuretic peptide (pro-ANP) for the identification of patients with atrial fibrillation with an onset of less than 48 hours ago

ActiveUS9128103B2Increase opportunitiesSlows phase depolarizationDisease diagnosisBiological testingAtrial natriuretic peptideBrain natriuretic peptide

Owner:BRAHMS GMBH +2

An assembled energy-saving anode steel claw for an aluminum electrolytic cell and its assembly method

The invention discloses an aluminum electrolysis cell assembly type energy-saving anode steel claw and an assembling method of the aluminum electrolysis cell assembly type energy-saving anode steel claw. The steel claw comprises a claw core, the outer side of an upper portion main rod and the top and side faces of a middle transverse rod of the claw core are sleeved with a shell, branch rods are sleeved with protection casing pipes, the bottom face is covered with a lower protection plate, the shell and the protection casing pipes are fixed to the claw core through branch rod bolts, and the claw core is made from metal aluminum. The assembling method comprises the steps that 1, the claw core, the shell, the lower protection plate and the protection casing pipes are manufactured; and the claw core, the shell and the protection casing pipes are drilled; 2, the claw core is sleeved with the shell, the bottom of the claw core is covered with the lower protection plate, and the bottom branch rods are sleeved with the protection casing pipes and fixed through the branch rod bolts; 3, an aluminum plate is welded between an aluminum guide rod and the claw core; 4, a connection steel plateis welded to the top end of the shell; and 5, the connection steel plate and the aluminum guide rod are fixed through guide rod bolts. By means of the steel claw structure, multiple defects of a steelclaw adopted in traditional electrolysis production can be overcome.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

Method for electrically contacting a piezoelectric ceramic

ActiveUS10074797B2Stable and rugged contactingProlong lifePiezoelectric/electrostrictive device manufacture/assemblyMechanical vibrations separationTransducerCeramic

A method for electrically contacting a piezoelectric ceramic includes: providing the piezoelectric ceramic having electrodes for electrically contacting the piezoelectric ceramic and having a flexible, electrically conductive film; producing a composite by applying the flexible, electrically conductive film at least partially to an electrode of the piezoelectric ceramic; forming a durable, electrically conductive connection between the flexible, electrically conductive film and the electrode of the piezoelectric ceramic. Also a sound transducer, as well as a sound transducer array produced using the method for electrically contacting a piezoelectric ceramic.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com