Stepped piezoelectric energy collector based on laser surface thinning and preparation method

A piezoelectric energy, stepped technology, applied to piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve problems such as poor matching performance, and achieve high precision and reliability Strong controllability and high output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

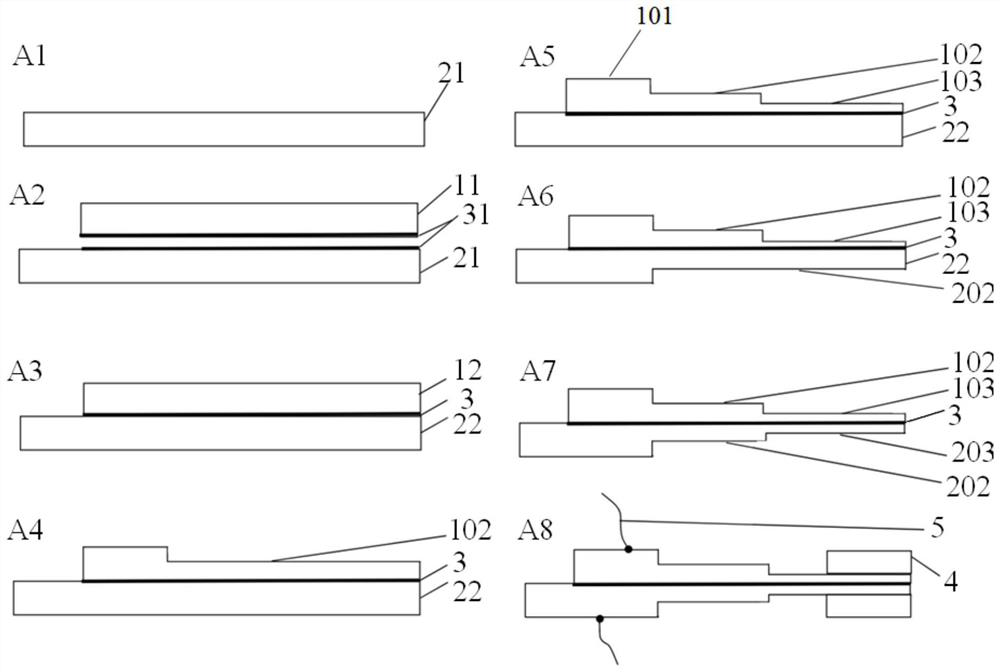

[0037] A method for preparing a stepped piezoelectric energy harvester based on laser surface thinning, comprising the following steps:

[0038] 1) Select the metal substrate 21, and perform 1-5min ultrasonic cleaning and 5-10min drying treatment on the metal substrate 21;

[0039] 2) Select the piezoelectric substrate 11, and screen-print a 2-8 μm adhesive material on the lower side of the piezoelectric substrate 11 and the upper side of the metal substrate 21, apply a clamping pressure of 0.1-1 MPa for clamping with a clamp, and place 50-200 ℃, vacuum degree of 60-90% in a vacuum oven for 4-6 hours to carry out thermocompression bonding to obtain the piezoelectric base layer 12, adhesive layer 3 and metal base layer 22 arranged in sequence from top to bottom, take it out and cool To room temperature, the cantilever beam blank is obtained;

[0040] 3) Fix the cantilever beam blank on the laser platform, and make the piezoelectric base layer 12 on the upper side, then set the...

Embodiment 1

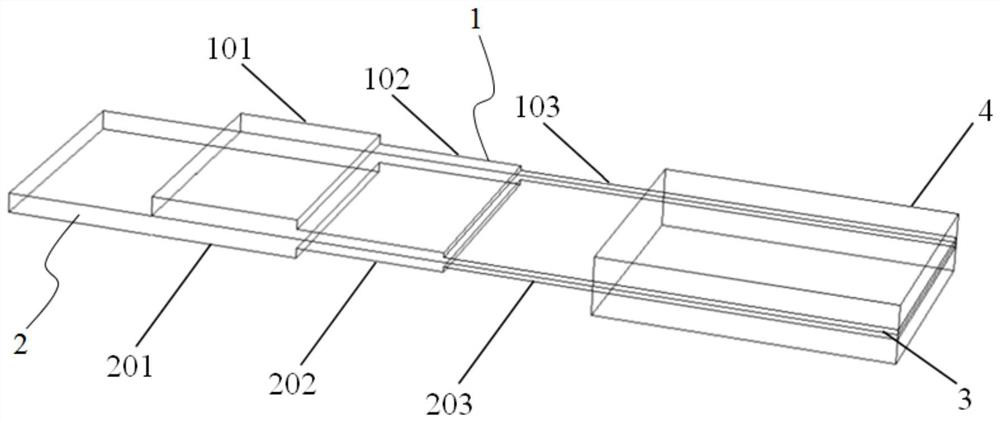

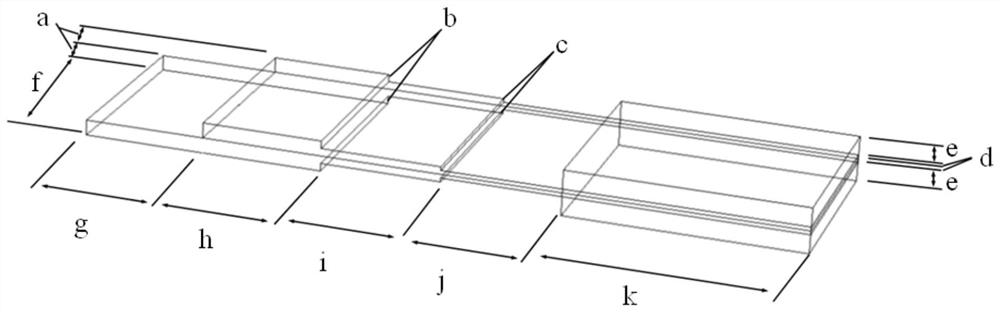

[0050] A stepped piezoelectric energy harvester based on laser surface thinning, including a cantilever beam, and fixing devices and mass blocks 4 arranged at both ends of the cantilever beam, wherein the structure of the cantilever beam is as follows figure 1 The shown includes a bonding layer 3 and a piezoelectric layer 1 and a metal substrate layer 2 symmetrically arranged on both sides of the bonding layer 3, and along the length direction of the cantilever beam pointing to the proof mass 4, the piezoelectric layer 1 and the metal substrate layer 2 The thickness decreases gradually in a step-like manner.

[0051] Specifically, the stepped structure on the piezoelectric layer 1 includes a first piezoelectric stepped layer 101, a second piezoelectric stepped layer 102, and a third piezoelectric stepped layer 103 with successively decreasing thicknesses, and the stepped structure on the metal substrate layer 2 The structure includes a first stepped substrate layer 201, a seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com