An assembled energy-saving anode steel claw for an aluminum electrolytic cell and its assembly method

A technology of aluminum electrolytic cell and anode steel claw, which is applied to the field of assembled energy-saving anode steel claw of aluminum electrolytic cell and its assembly, can solve the problems of depolarization, large pressure drop of steel claw, large resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

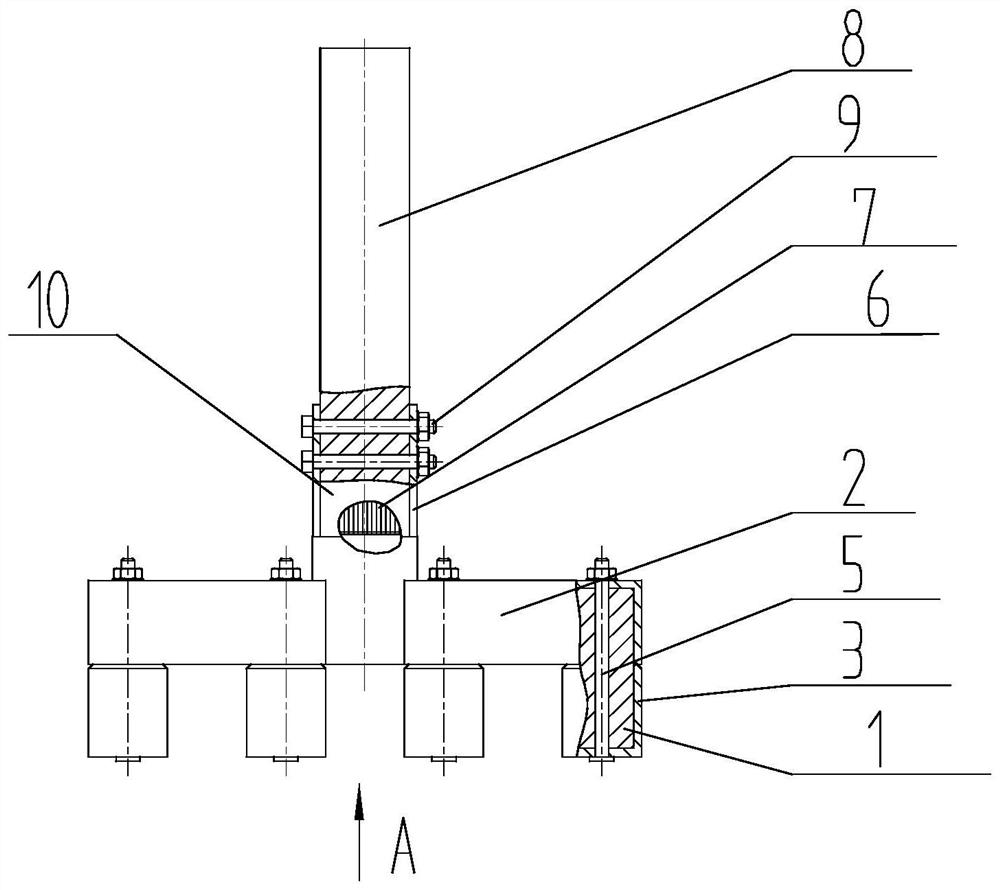

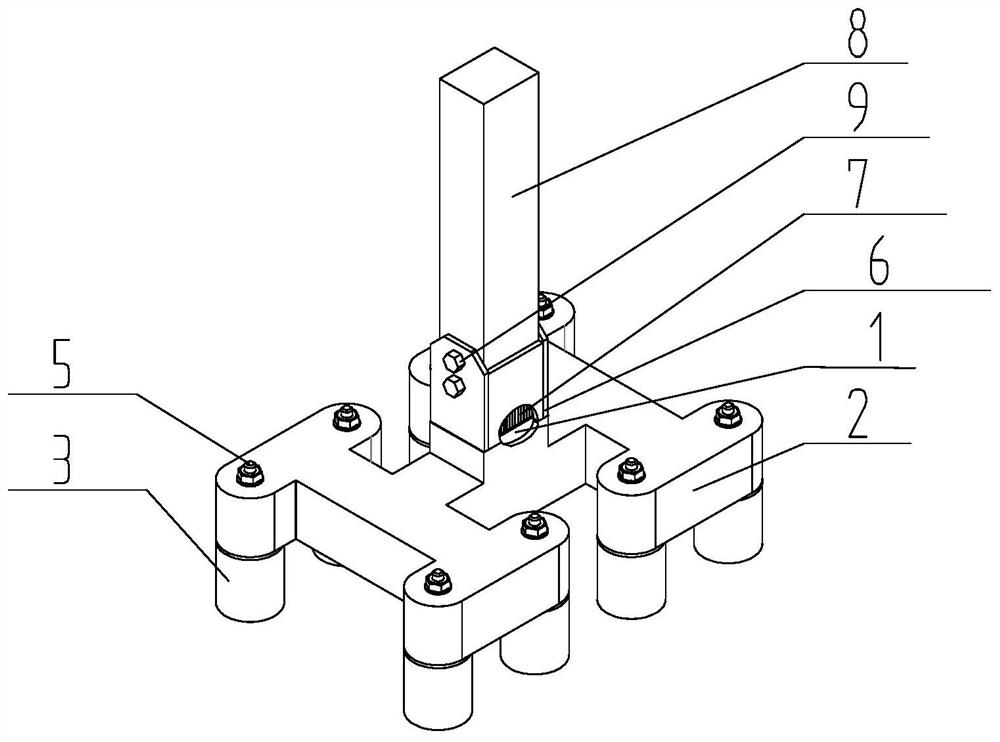

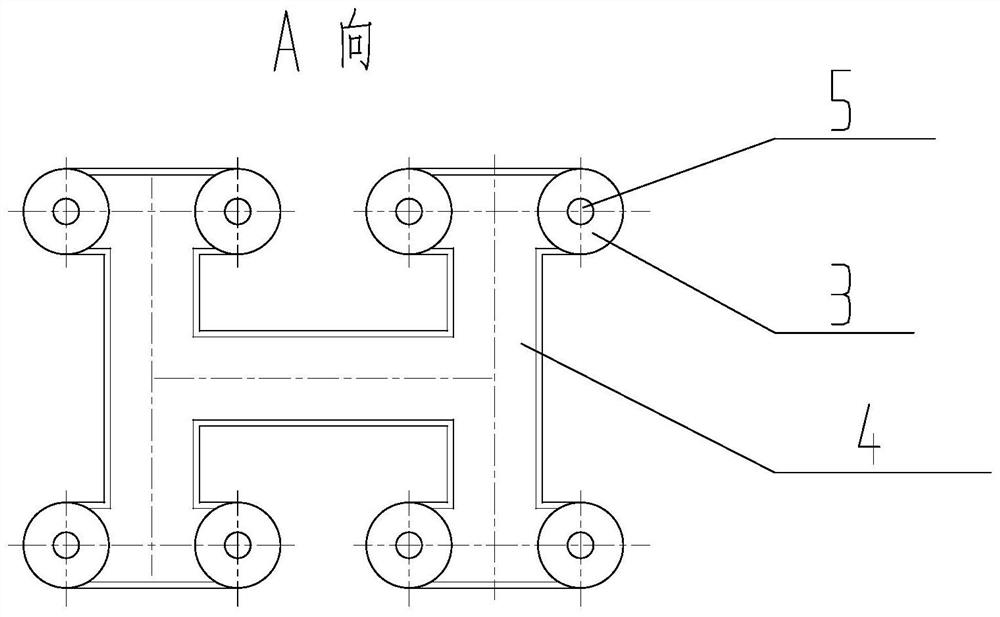

[0030] Aluminum electrolytic cell assembled energy-saving anode steel claw structure such as figure 1 As shown, the axonometric drawing is shown as figure 2 As shown, the A-direction structure is as follows image 3 As shown, it includes claw core, shell and protective sleeve. The claw core is composed of upper main rod, middle cross bar and multiple bottom support rods. The lower end of an upper general rod is connected with the middle part of a first-level cross bar. The two ends of each are respectively connected to the middle of a second-level crossbar, and each end of the second-level crossbar is provided with a bottom strut, and there are 8 bottom struts in total;

[0031] The outside of the upper main bar of the claw core, the top surface of the middle cross bar and the side of the middle cross bar are covered with a shell, and each bottom support is respectively covered with a protective sleeve; the bottom surface of the middle cross bar of the claw core is covered w...

Embodiment 2

[0042] Aluminum electrolytic cell assembled energy-saving anode steel claw structure such as Figure 4 As shown, the axonometric drawing is shown as Figure 5 As shown, the A-direction structure is as follows Figure 6 As shown, the bottom end of the upper main bar of the claw core is connected with the middle part of the cross bar, and four bottom struts are evenly distributed below the cross bar, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com