Mold repairing machine

A technology for repairing machines and molds, applied in the field of repairing machines, can solve the problems of long grinding time, long waste time, low work efficiency, etc., and achieve the effects of high grinding efficiency, reasonable structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

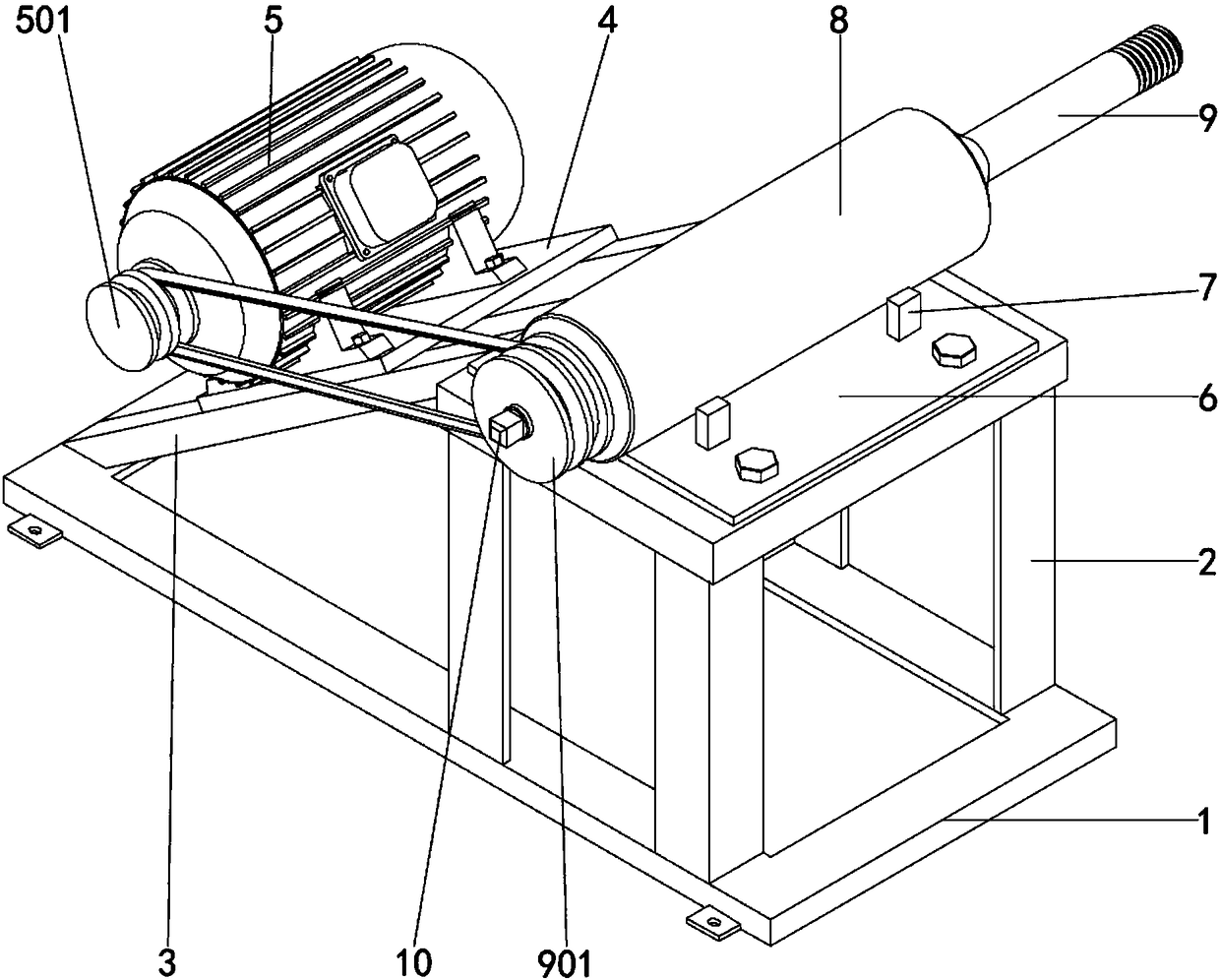

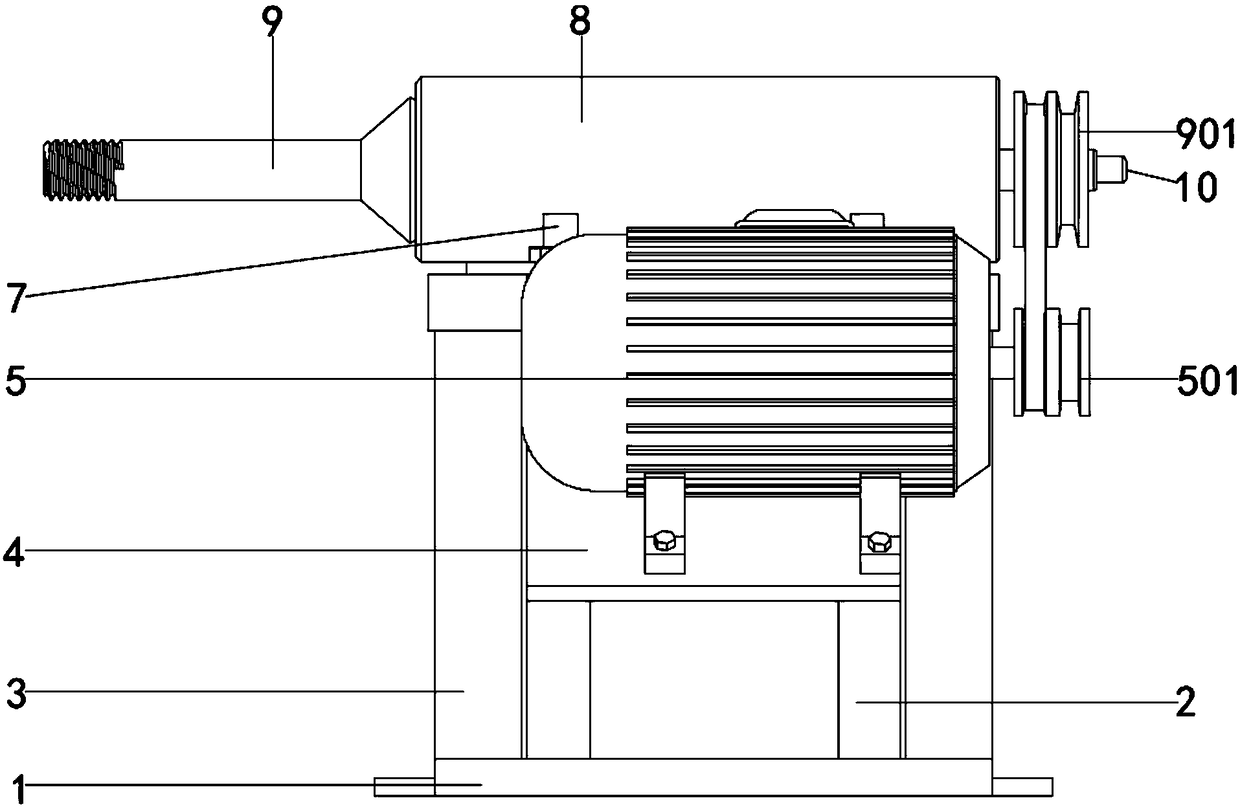

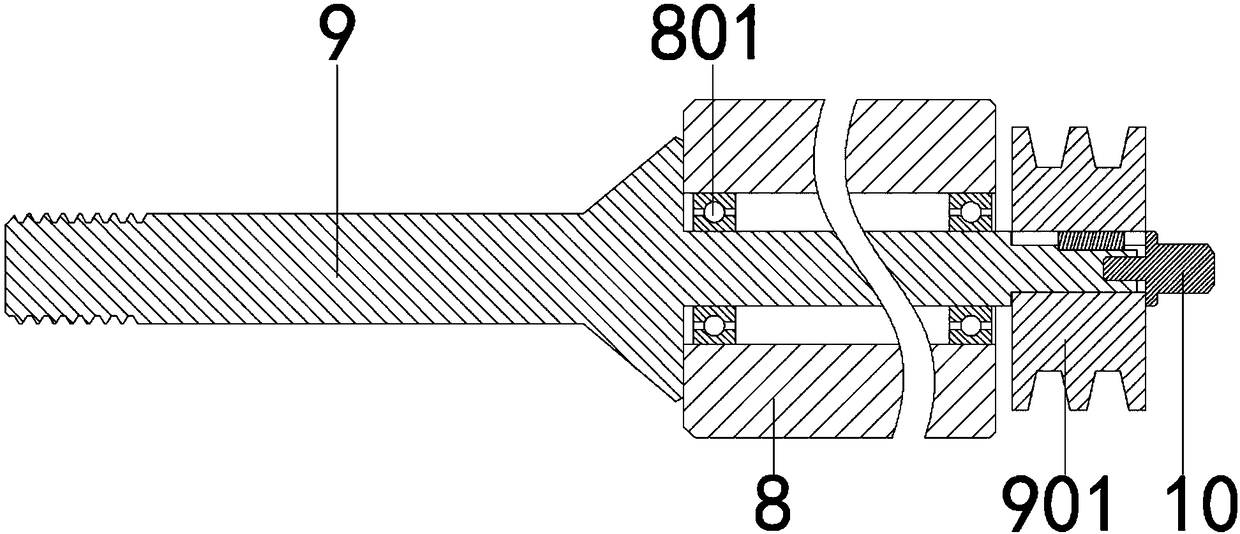

[0028] A mold repairing machine, comprising: a base 1, a base 2, a brace 3, a motor mounting plate 4, a motor 5, a driving pulley 501, a sleeve mounting plate 6, a limit block 7, a sleeve 8, a bearing 801, a rotating Shaft 9, driven pulley 901, lock nut 10; the top of the right side of the base 1 is welded with a stool-shaped base 2, and the left end of the base 1 and the left side of the top of the base 2 are welded with two parallel braces 3, and the diagonal brace 3 is inclined at 60 degrees to the ground plane; the middle part of the diagonal brace 3 is welded with a rectangular motor mounting plate 4, and the upper part of the motor mounting plate 4 is fixed with a motor 5 by bolts, and the front of the motor 5 The driving pulley 501 is installed on the side through a flat key and a keyway; the top of the base 2 is fixed with a rectangular sleeve mounting plate 6 by bolts, and the top of the sleeve mounting plate 6 is welded with four rectangular limit blocks in a rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com