Assembly honeycomb steel plate shear wall

A steel plate shear wall, honeycomb type technology, applied in the direction of walls, building components, buildings, etc., to achieve the effect of simple construction, reduced cost, and improved lateral stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

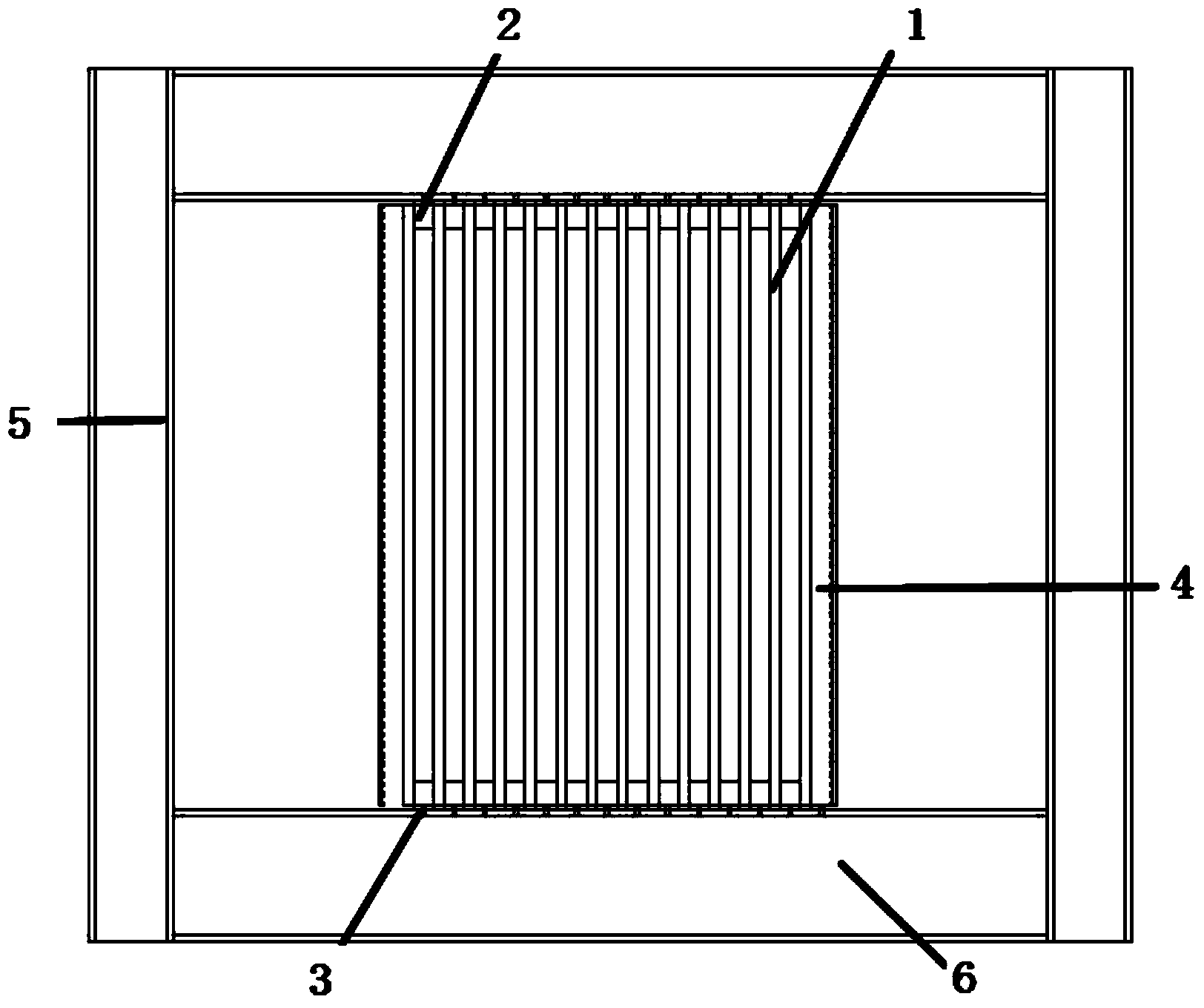

[0019] The prefabricated honeycomb steel plate shear wall is composed of embedded honeycomb steel plate 1, angle steel 2, high-strength bolt 3, vertical edge member 4, frame column 5, frame beam 6, connector 7 and profiled steel plate 8; The embedded honeycomb steel plate 1 is connected with the angle steel 2 and the vertical edge member 4; the angle steel 2 is connected with the frame beam 6.

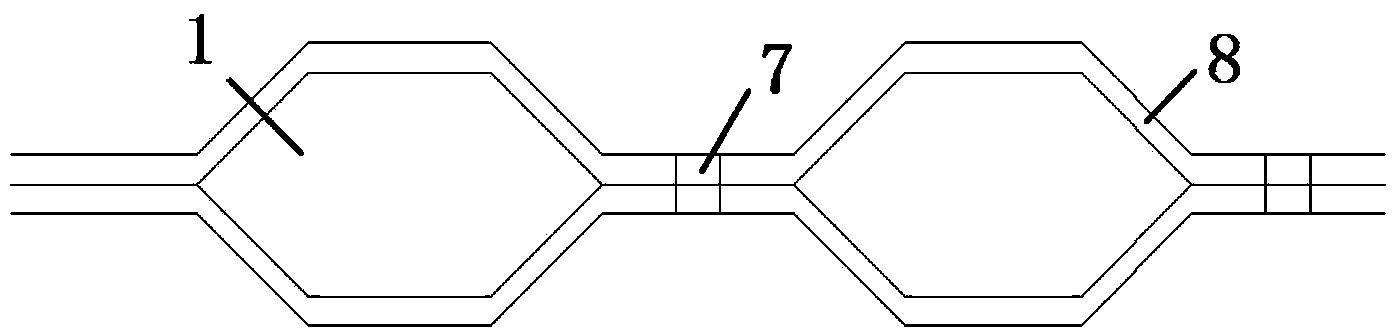

[0020] In the above-mentioned prefabricated honeycomb steel plate shear wall, in the above-mentioned prefabricated honeycomb steel plate shear wall, the embedded honeycomb steel plate 1 is made of profiled steel plate 8 with crests facing each other, and troughs facing each other. 7 are connected. The vertical edge member 4 is composed of double angle steels, distributed on both sides of the embedded honeycomb steel plate 1, and connected with the embedded honeycomb steel pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com