A Method of Controlling the Root Gap and Warpage of Welding Joints on One Side of Thin Plate

A technology of root gap and joint root, which is applied in the field of single-face welding of thin plates, can solve the problems affecting the quality of the weld seam and the welding process, warping deformation, poor flexibility, etc., and achieves a significant effect of misalignment control, free separation, and positioning The effect of flexible and accurate spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

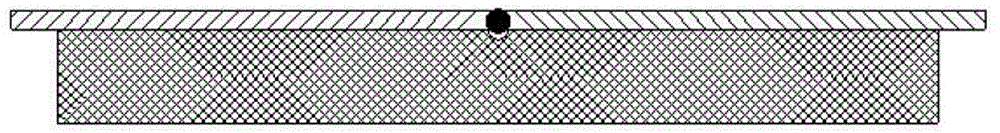

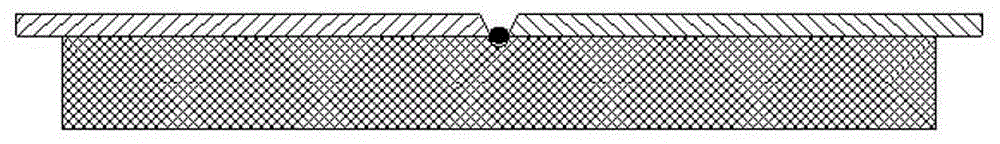

[0055] The method of dynamically controlling the root gap and warping deformation of the single-face welding joint of the thin plate with welding includes: the thickness of the aluminum alloy thin plate is δ=3mm, according to the δ≤4mm in Table 1, the I-shaped groove welding is adopted, see Figure 9 , the root gap is 1.5mm;

[0056] Make a circular convex roller 2 that controls the root gap with welding positioning. The section of the circular convex part 21 is an I-shaped structure, the convex height is 4mm (including the circular top), and the 1mm exceeding the plate thickness In the forming groove 51 of the backing plate 5 under the thin plate;

[0057] Assemble the circular convex roller 2, TIG welding torch (with filler wire), and extrusion wheel 3 in sequence, and place the device on the aluminum alloy sheet to be welded. Automated TIG wire-filled welding, due to the circular forming groove below, successfully completes the TIG welding of single-sided welding and doubl...

Embodiment 2

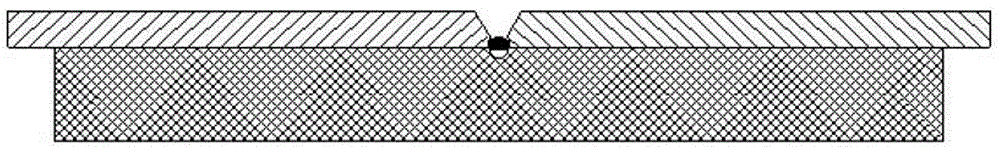

[0059] The method of dynamically controlling the root gap and warping deformation of the single-face welding joint of the thin plate with welding includes: the thickness of the aluminum alloy thin plate is δ=5mm, according to the δ>4mm in Table 1, the V-shaped groove welding is adopted, see Figure 11 , the groove angle is 65°, the blunt edge height at the root is 2mm, and the groove gap is 2.5mm;

[0060] Make a circular convex roller 2 that controls the root gap with welding positioning, the section of the circular convex part 21 of the circular convex roller 2 is an inverted Y-shaped structure, and the total height of the convex is 6.5mm (including the circular top) , the 1.5mm exceeding the plate thickness δ is located in the forming groove 51 of the backing plate 5 under the aluminum alloy sheet;

[0061] Assemble the circular convex roller 2, TIG welding torch (with filler wire), extrusion wheel 3, and extrusion force device 7 in sequence, place the device on the aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com