Synchronous construction method for constructing suspended rail beam and roof

A technology of simultaneous construction and construction method, applied in the direction of house structure support, house structure support, construction, etc., can solve the problems of increasing the cost of scaffolding, reducing the density of scaffolding, long density of scaffolding, etc., to reduce the cost of erection and material turnover. Costs, reduction of secondary scaffolding, good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

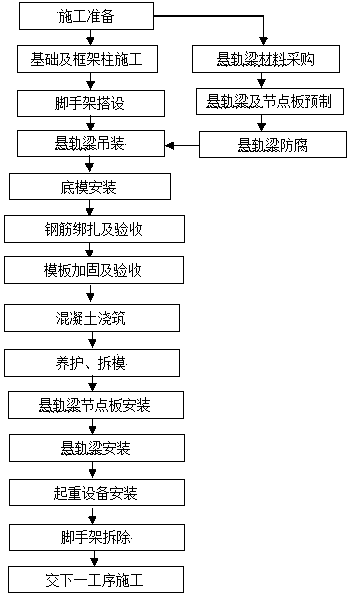

[0033] figure 1 As shown, the process flow of the present invention includes foundation and frame column construction, scaffold erection, roof construction, suspension rail beam hoisting, base form installation, steel bar binding, formwork support and reinforcement, concrete pouring, maintenance and formwork removal, suspension rail Beam gusset plate installation, suspension rail beam installation, crane equipment installation, scaffolding removal, characterized in that after the foundation and frame columns are constructed, scaffolding is erected under the projected area of the roof, and then the suspension rail beams are hoisted to the position below the installation, and then the roof is installed And the roof beam bottom formwork, binding steel bars, side formwork reinforcement, concrete pouring, when the condition of removing the formwork and scaffolding is achieved after curing, the formwork is removed, and the suspension rail beam gusset plate is installed, the suspens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com