Method for fixing mine vertical shaft device

A shaft shaft and equipment technology, which is applied in the field of equipment for fixed shaft shafts in mine shafts, can solve problems such as unfavorable shaft rapid excavation and installation, damage to shaft wall integrity, and reduced waterproof effect, so as to increase strength and reduce later deformation , Improve the effect of waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

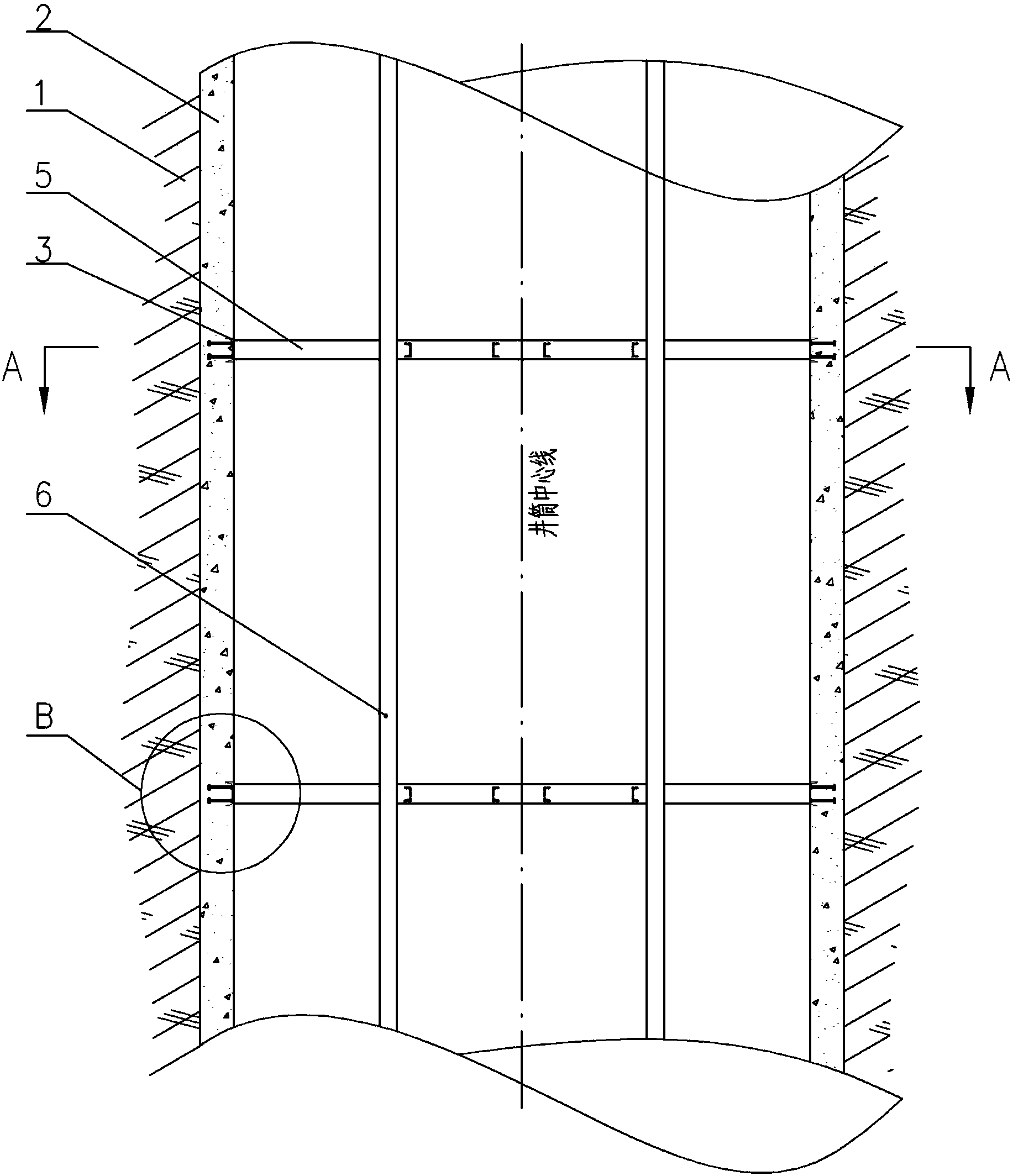

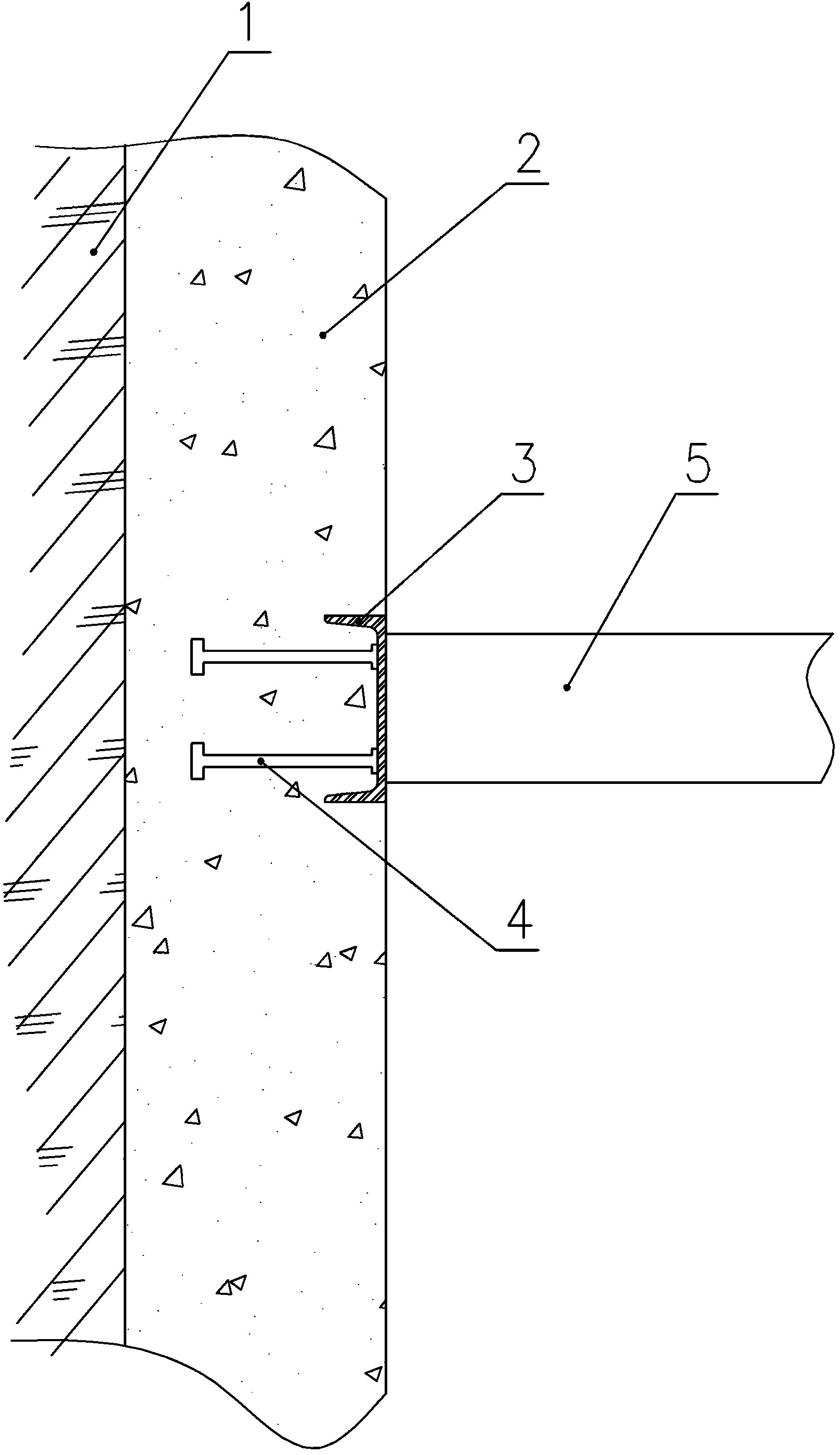

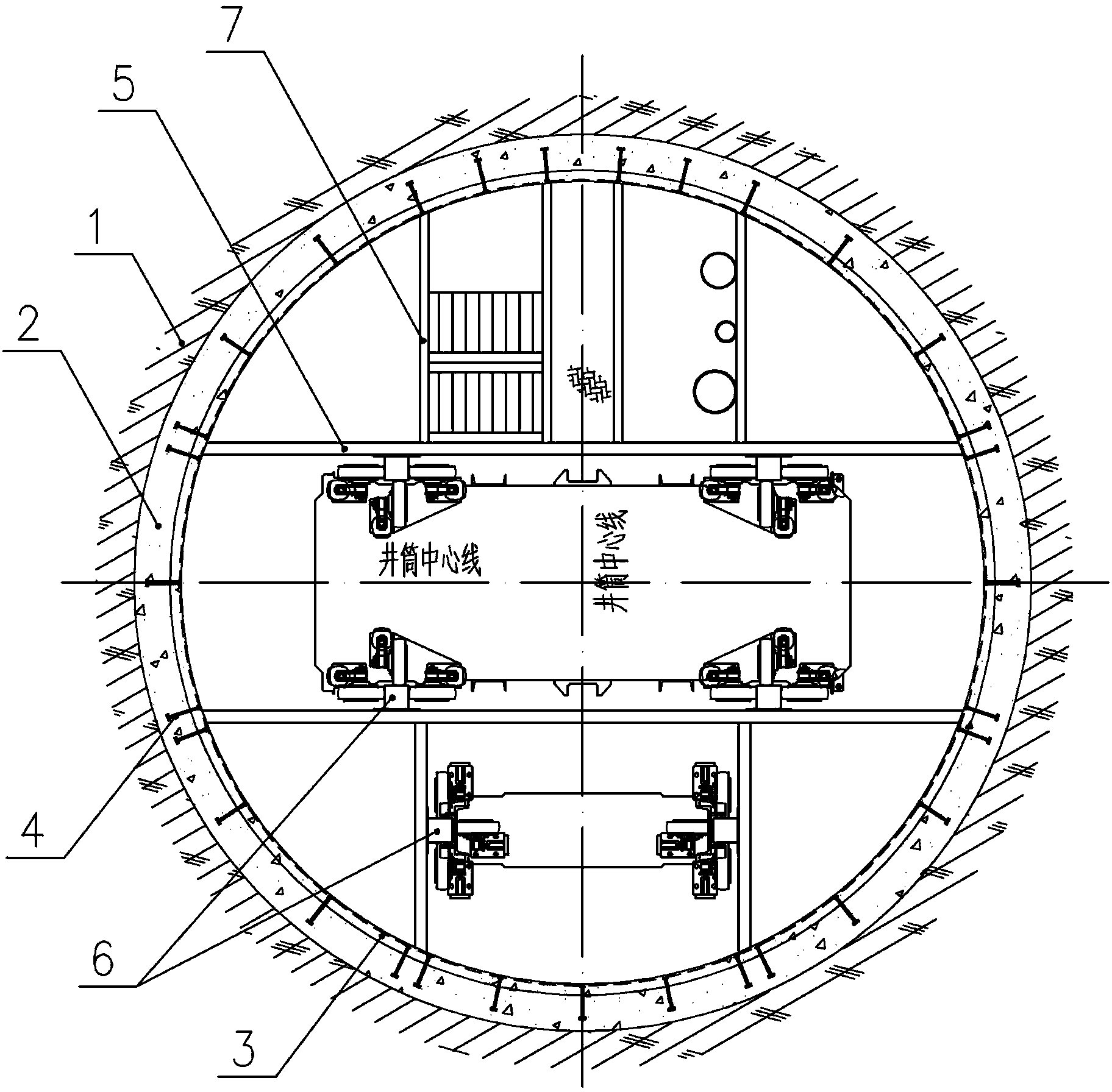

[0013] preferred embodiment, such as Figure 1 to Figure 3 As shown, the method for fixing mine vertical shaft shaft equipment disclosed by the present invention includes the following steps in sequence: processing and manufacturing steel well ring 3 according to the inner diameter of the shaft wall and dividing them into blocks, measuring and positioning the installation position of steel well ring 3 and steel well ring 3 The underground assembly of the steel well ring 3, the well wall embedding of the steel well ring 3 and the fixing of the tank beam 5, the well beam 7 and the steel well ring 3.

[0014] When making the steel well ring 3, according to the cross-sectional dimensions and stress conditions of the tank beam 5 and the well beam 7, the steel well ring 3 is made of channel steel with the opening facing outwards to fix the tank beam 5 and the well beam 7 by cold bending, ensuring The inner diameter of the steel well ring 3 is the same as that of the well wall 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com