A configuration method of vibration sensor for wind turbine gearbox based on structural analysis

A vibration sensor and structural analysis technology, applied in wind turbines, machines/engines, engines, etc., can solve the problem that the location and number of sensors cannot guarantee the most effective vibration signal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with specific embodiments.

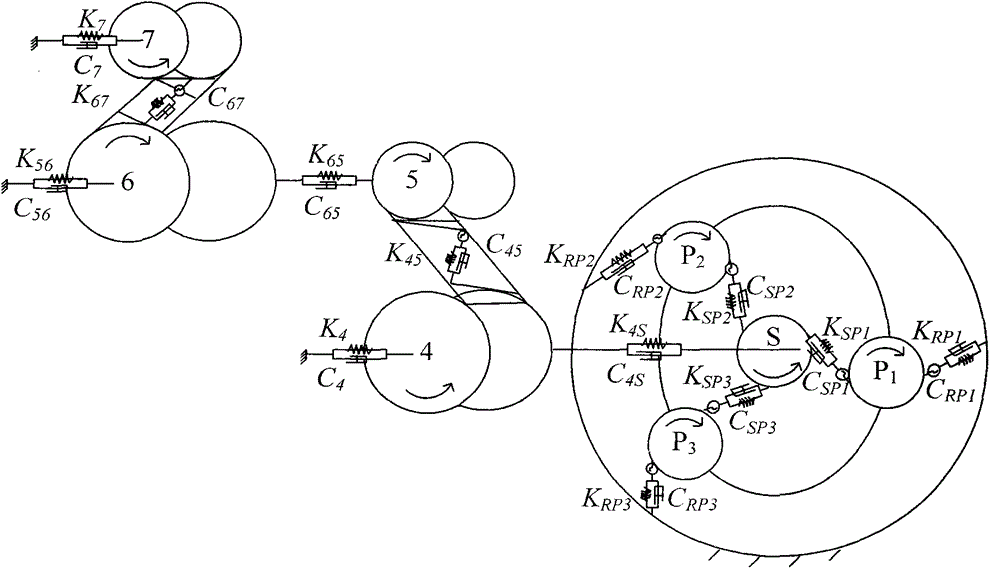

[0019] 1 Configuration method of vibration sensor for wind turbine gearbox based on structural analysis

[0020] The vibration sensor configuration and method of wind turbine gearbox for structural analysis mainly includes the following steps: 1) Analyze the structure of the gearbox system; 2) Build the dynamic model of the gearbox system; 3) Apply the structural analysis method to configure the gearbox sensor. Let's introduce them separately.

[0021] 1.1 Analyze the structure of the gearbox system

[0022] The structures commonly used in wind turbine gearboxes include one-stage planet and two-stage parallel, two-stage planet and one-stage parallel, single-stage planet (semi-direct drive), two-stage planet, and one-stage planet and one-stage parallel. First determine which structure the sensor gearbox to be configured belongs to, and then define each component of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com