Axial eddy current damper based on spiral transmission method

An eddy current damper and eddy current damping technology, applied in the direction of spring/shock absorber, vibration suppression adjustment, spring, etc., can solve the problems of difficulty in making large damping coefficient and low working frequency, and achieve simple structure, low cost, The effect of improved control efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

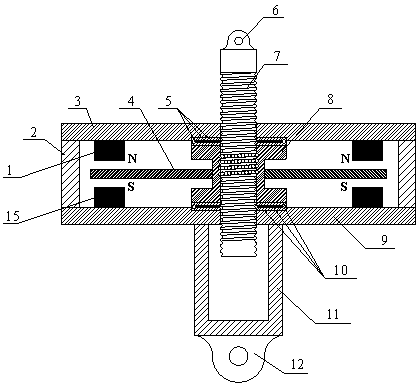

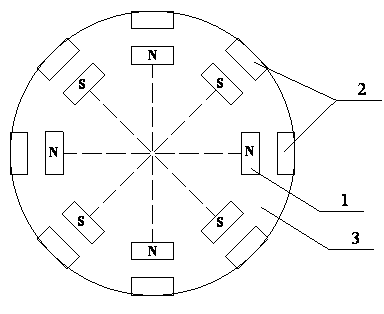

[0032] Such as figure 1As shown, an axial eddy current damper based on a screw transmission method includes a screw auxiliary transmission assembly and a rotary eddy current damping generator. The upper disk 3 and the lower disk 9 are made of magnetically permeable material, and the helical auxiliary transmission assembly runs through the upper disk 3 and the lower disk 9 along the axial direction of the upper disk 3 and the lower disk 9, and on the upper Between the disc 3 and the lower disc 9, there is a rotating disc 4 made of conductive material parallel to the upper disc 3. The rotating disc 4 is installed on the helical auxiliary transmission assembly and is made with the helical auxiliary transmission assembly. Rotational movement; 8 pairs of magnets are also arranged between the upper disk 3 and the lower disk 9, each pair of magnets includes an upper magnet 1 and a lower magnet 15 installed below the upper magnet 1 along the axial direction of the upper disk 3, so In...

Embodiment 2

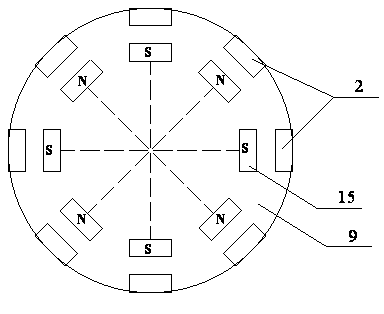

[0037] Such as Figure 4 As shown, an axial eddy current damper based on a screw transmission method includes a screw auxiliary transmission assembly and a rotary eddy current damping generator. The upper disk 3 and the lower disk 9 are made of magnetically permeable material, and the helical auxiliary transmission assembly runs through the upper disk 3 and the lower disk 9 along the axial direction of the upper disk 3 and the lower disk 9, and on the upper Between the disc 3 and the lower disc 9, there is a rotating disc 4 made of magnetically permeable material parallel to the upper disc 3. The rotating disc 4 is installed on the helical auxiliary transmission assembly and moves with the helical auxiliary transmission assembly. Rotating motion; 8 pairs of magnets are also arranged between the upper disk 3 and the lower disk 9, each pair of magnets includes an upper magnet 1 and a lower magnet 15 installed below the upper magnet 1 along the axial direction of the upper disk 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com