Testing system for comprehensive quality of main spraying nozzle of air-jet loom and testing method

A quality testing and main nozzle technology, which is applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc. It can solve the problem that the quality of the main nozzle cannot be objectively understood and rationally judged, and achieve reliable testing data. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

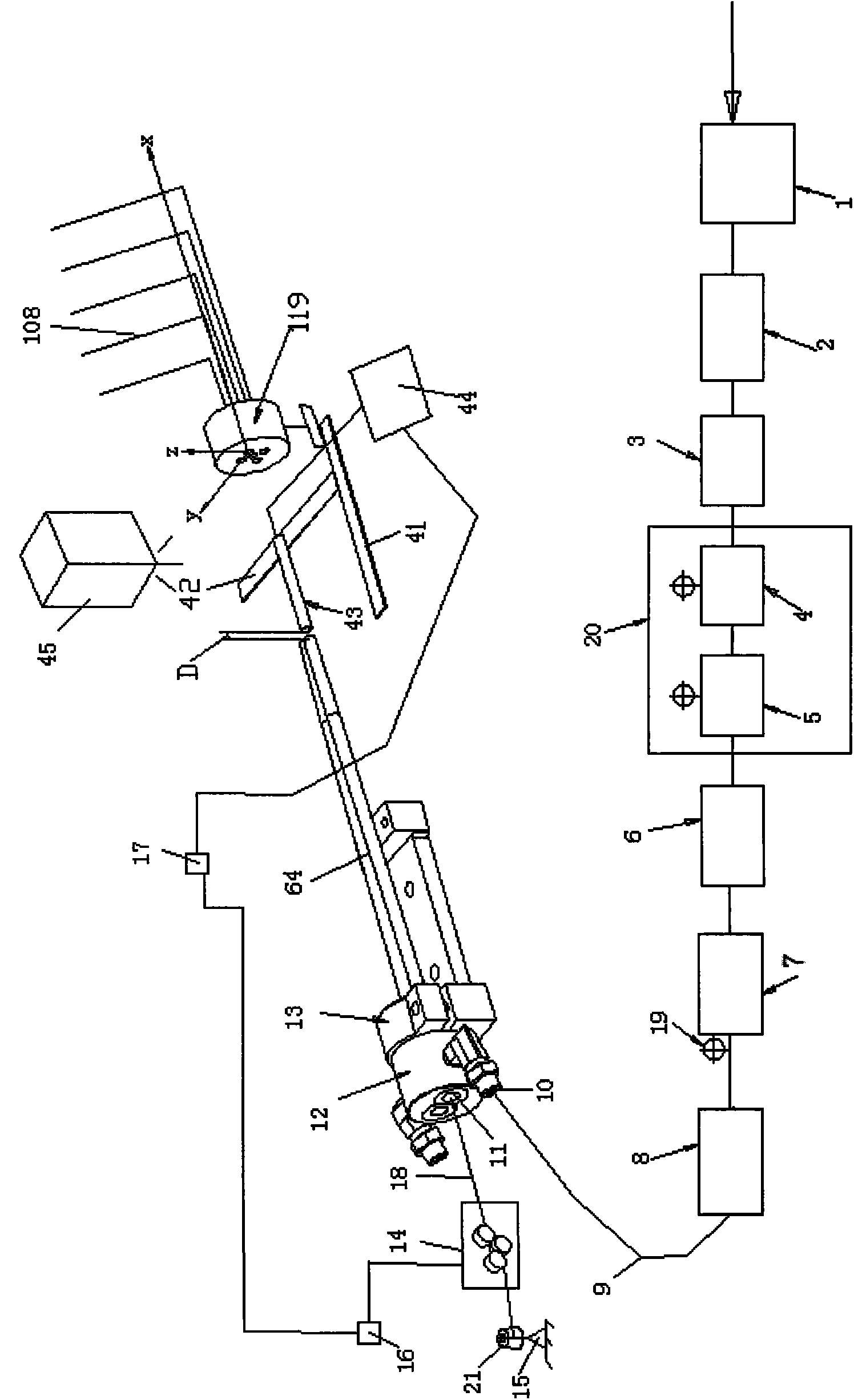

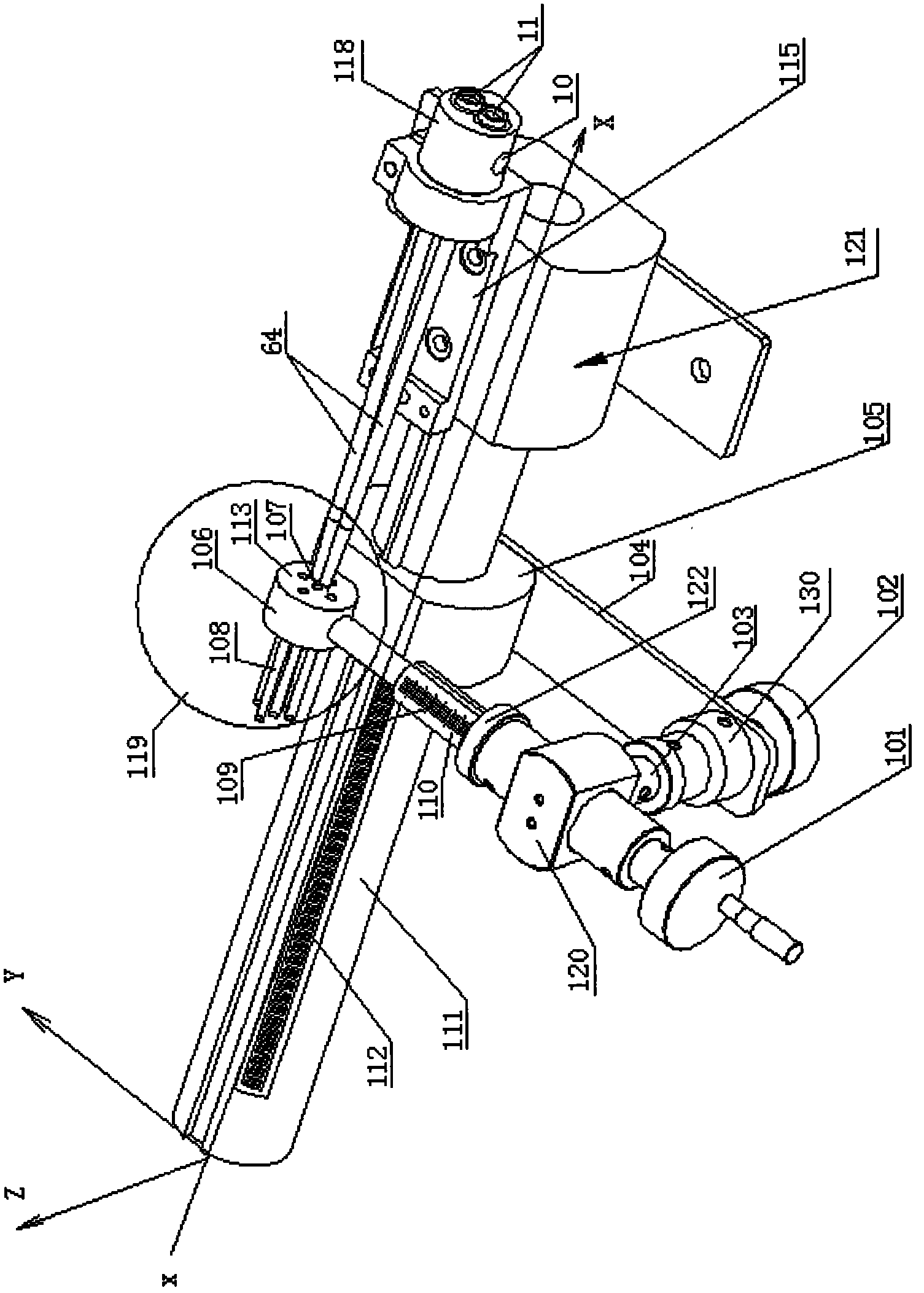

[0027] Such as figure 1 As shown, the testing device of the present invention includes a constant air pressure providing device, a weft yarn tension testing device, a stroboscope, an anemometer and a main nozzle airflow actual intersection testing head 119, a testing head center position adjustment device and a measuring device.

[0028] The constant air pressure providing device includes a compressed gas supply device, a precision pressure regulating device 20 , a flow meter 7 and a pressure gauge 19 . The air supply device, precision pressure regulating device 20, flowmeter 7 and solenoid valve 8 are pipe-connected in sequence, and the pressure gauge 19 is installed in parallel on the air supply pipe 9 closest to the outlet of the flowmeter 7. The outlet of the flowmeter 7 and the pressure gauge 19 The parallel nodes are connected to the air guide hole 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com