Thermal analysis method of TiO2 crystallization by water supporting at low temperature

A low-temperature crystallization and thermal analysis technology, applied in the field of analysis and testing, can solve the problems of inability to obtain accurate phase transition temperature or phase transition time, difficult detection of crystalline phase transition peaks, and changing crystallization environment, so as to overcome the volatilization of water and prevent changes. , The effect of accurate thermal analysis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] After careful selection, we choose Dow Corning silicone oil (DOW CORNING 200 FLUID, dynamic viscosity coefficient is 1000cst, density is 0.971kg / m 3 ) as an overlay.

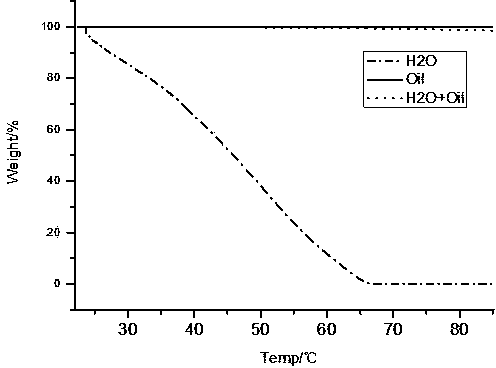

[0029] Thermal analysis experiments were done on Diamond TG-DTA (Perkin-Elmer, USA). Weigh about 10mg of water, silicone oil, and water with silicone oil added as a covering layer, put them into a conventional aluminum oxide crucible without a cover, and raise the temperature to 85°C at a rate of 5°C / min, and use argon as a protective atmosphere during the heating process (purity 99.99%), the flow rate is 100ml / min.

[0030] The obtained TGA (Thermogravimetric Analysis, thermogravimetric analysis) data is processed as attached figure 1 As shown, it can be seen that if the pure water is not covered, it is basically completely volatilized when the temperature rises to 70°C, while the pure silicone oil is very stable before 85°C, with almost no weight loss. The pure water sample with silicone oil as the c...

Embodiment 2

[0033] Preparation of TiO by the classic sol-gel method 2 For nanomaterials, see Jean, J.H. and T.A. Ring, Nucleation and growth of monosized titania powders from alcohol solution. Langmuir, 1986. 2(2): p. 251-255. Hydroxypropyl cellulose (HPC 0.2g) was dissolved in anhydrous ethanol (50ml) and deionized water (0.3ml) solution, stirred for half an hour; added butyl titanate (TBOT, 97%, 0.85 ml), stirred Mix until it appears foggy, and age for 3 hours; finally centrifuge, wash 3 times with absolute ethanol, wash 1 time with water, and disperse in 20 ml of deionized water. The diameter of the synthesized original sample is about 200nm as detected by TEM, and its phase is amorphous as detected by XRD.

[0034] After careful selection, we choose Dow Corning silicone oil (DOW CORNING 200 FLUID, dynamic viscosity coefficient is 1000cst, density is 0.971kg / m 3 ) as an overlay.

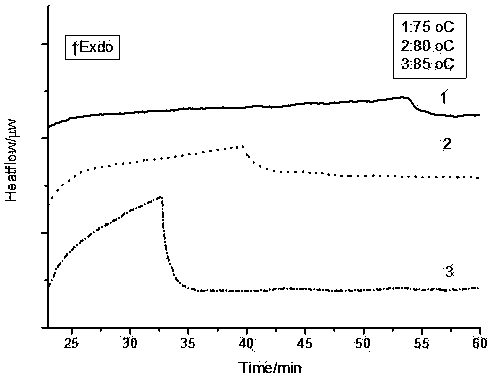

[0035] Thermal analysis experiments were done on Diamond TG-DTA (Perkin-Elmer, USA). with conventional...

Embodiment 3

[0039] Preparation of TiO by the classic sol-gel method 2 aqueous solution. Hydroxypropyl cellulose (HPC 0.2g) was dissolved in anhydrous ethanol (50ml) and deionized water (0.3ml) solution, stirred for half an hour; added butyl titanate (TBOT, 97%, 0.85 ml), stirred Mix until it appears foggy, and age for 3 hours; finally centrifuge, wash 3 times with absolute ethanol, wash 1 time with water, and disperse in 20 ml of deionized water. The diameter of the synthesized original sample is about 200nm as detected by TEM, and its phase is amorphous as detected by XRD.

[0040] After careful selection, we choose Dow Corning silicone oil (DOW CORNING 200 FLUID, dynamic viscosity coefficient is 1000cst, density is 0.971kg / m 3 ) as an overlay.

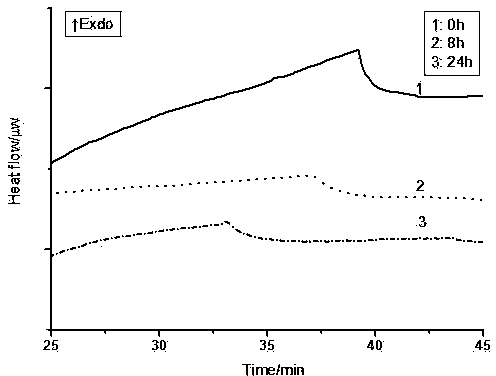

[0041] Thermal analysis experiments were done on Diamond TG-DTA (Perkin-Elmer, USA). The same batch of water-wetted TiO prepared 2 After the samples were placed in 0H, 8H and 24H respectively, the conventional uncapped Al 2 o 3 Weigh abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com