Composite prismatic lens

A prism sheet and prism technology, applied in prisms, nonlinear optics, instruments, etc., can solve the problems of mutual scratches on the diaphragm, dust or debris mixed in the diaphragm, and lower production and assembly qualification rate of the backlight module, etc. group yield, improved brightness and uniformity of light, good optical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

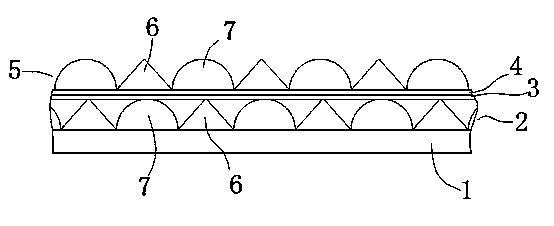

[0014] refer to figure 1 , a composite prism sheet, comprising a lower substrate layer 1, the lower substrate layer 1 has a lower prism layer 2, the lower prism layer 2 is provided with an adhesive layer 3, and the adhesive layer 3 is provided with a layer of upper substrate layer 4, and the upper substrate layer 4 is provided with a layer of upper prism layer 5;

[0015] The upper prism layer 5 and the lower prism layer 2 all include some rows of triangular prisms 6 and some rows of half cylinders 7, and the triangular prisms 6 and half cylinders 7 are alternately distributed and connected to each other at the lower ends. at the arc surface;

[0016] The triangular prism of the upper prism corresponds to the semi-cylinder of the lower prism, and the semi-cylindrical of the upper prism corresponds to the triangular prism of the lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com