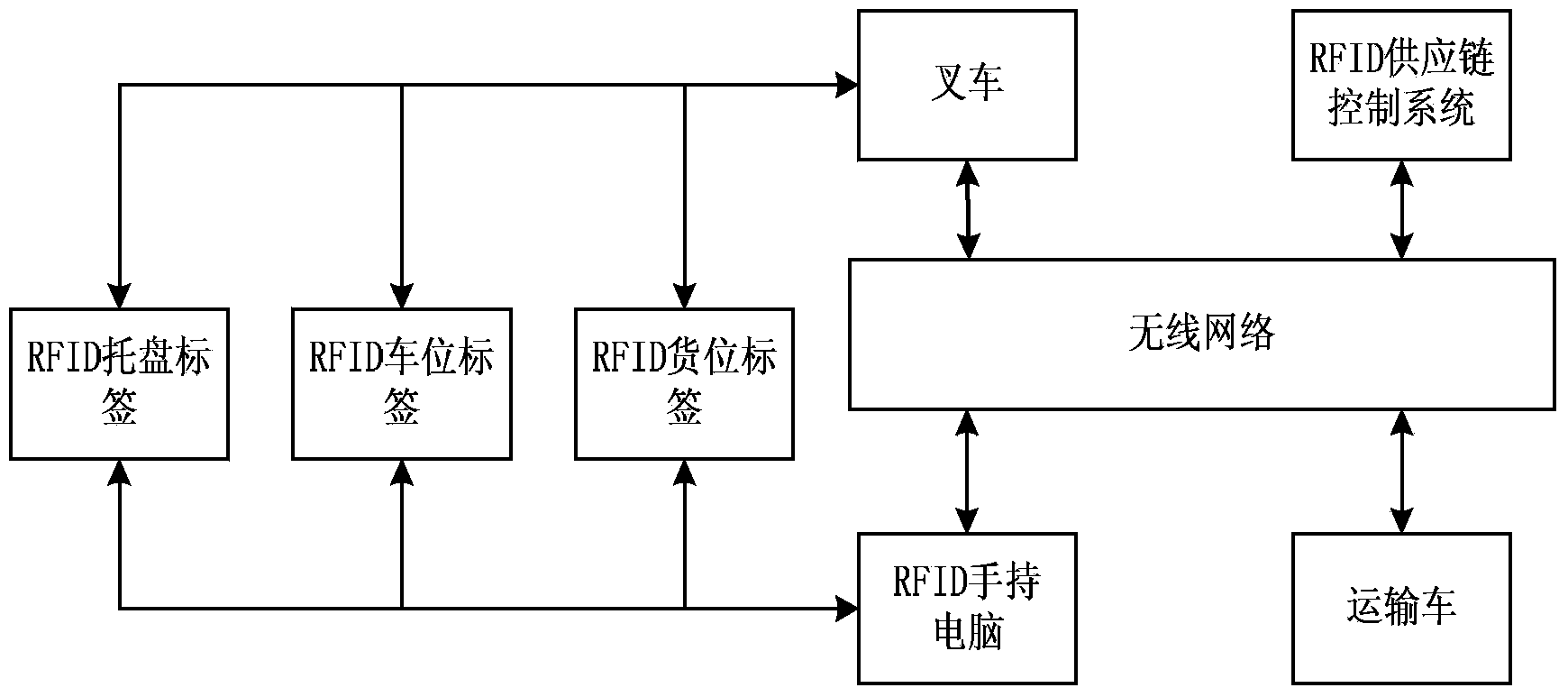

RFID logistics management system

A logistics management and logistics technology, applied in the field of the Internet of Things, can solve problems such as error-prone, low security, and inability to track goods in real time, and achieve high real-time and high security effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] This embodiment introduces the operation flow of the product from the off-line area to the completion of loading.

[0071] In the present invention, two RFID pallet electronic labels are pasted on both sides of each pallet, and the RFID supply chain control system will automatically assign a globally unique code to the RFID pallet electronic label to identify the unique identity of each pallet; at the same time, the RFID pallet electronic label The barcode corresponding to the label code is printed on the label as a backup.

[0072] When the product is offline, first check whether the pallet is intact and whether the status of the RFID pallet label is normal. When the product goes off-line and is transported to the pallet by the conveyor belt, the operators in the off-line area collect the barcode labels of each single product (single product) through the RFID handheld computer, and transport the single product (single product) to the pallet; at the same time, through t...

Embodiment 2

[0079] This embodiment introduces the operation flow of storage, storage, pallet recovery and defective product processing.

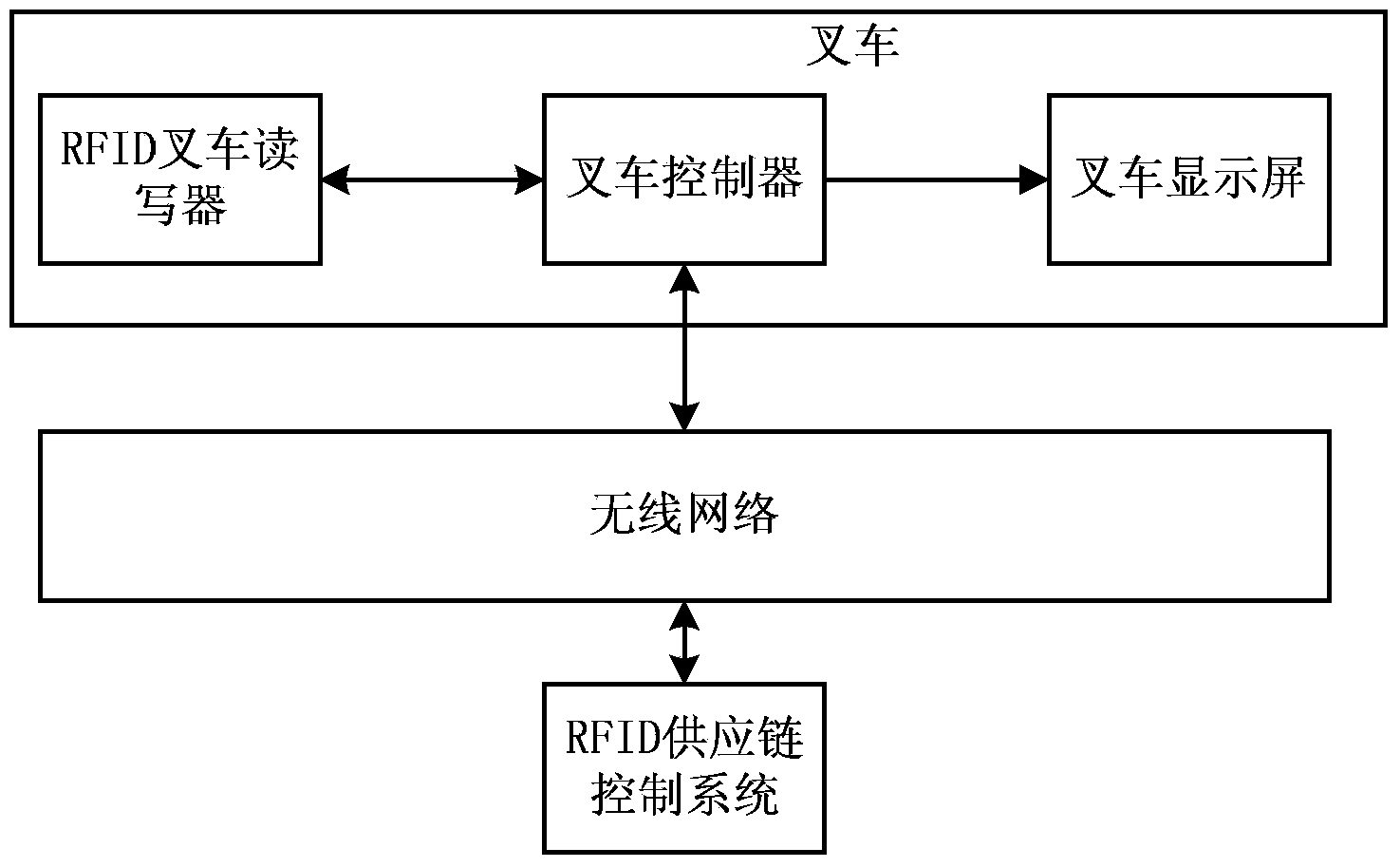

[0080] When the transport vehicle arrives at the destination warehouse, the RFID supply chain control system accepts the transfer order and sends an unloading order to the forklift after confirmation. After receiving the unloading order, the forklift unloads the goods from the transport vehicle to the temporary storage area, and reads and writes through the RFID forklift After automatic scanning by the forklift operator, it is confirmed by the forklift operator (that is, the forklift operator scans the RFID pallet label, obtains the number of pallet products, and compares and confirms it with the result of manual counting).

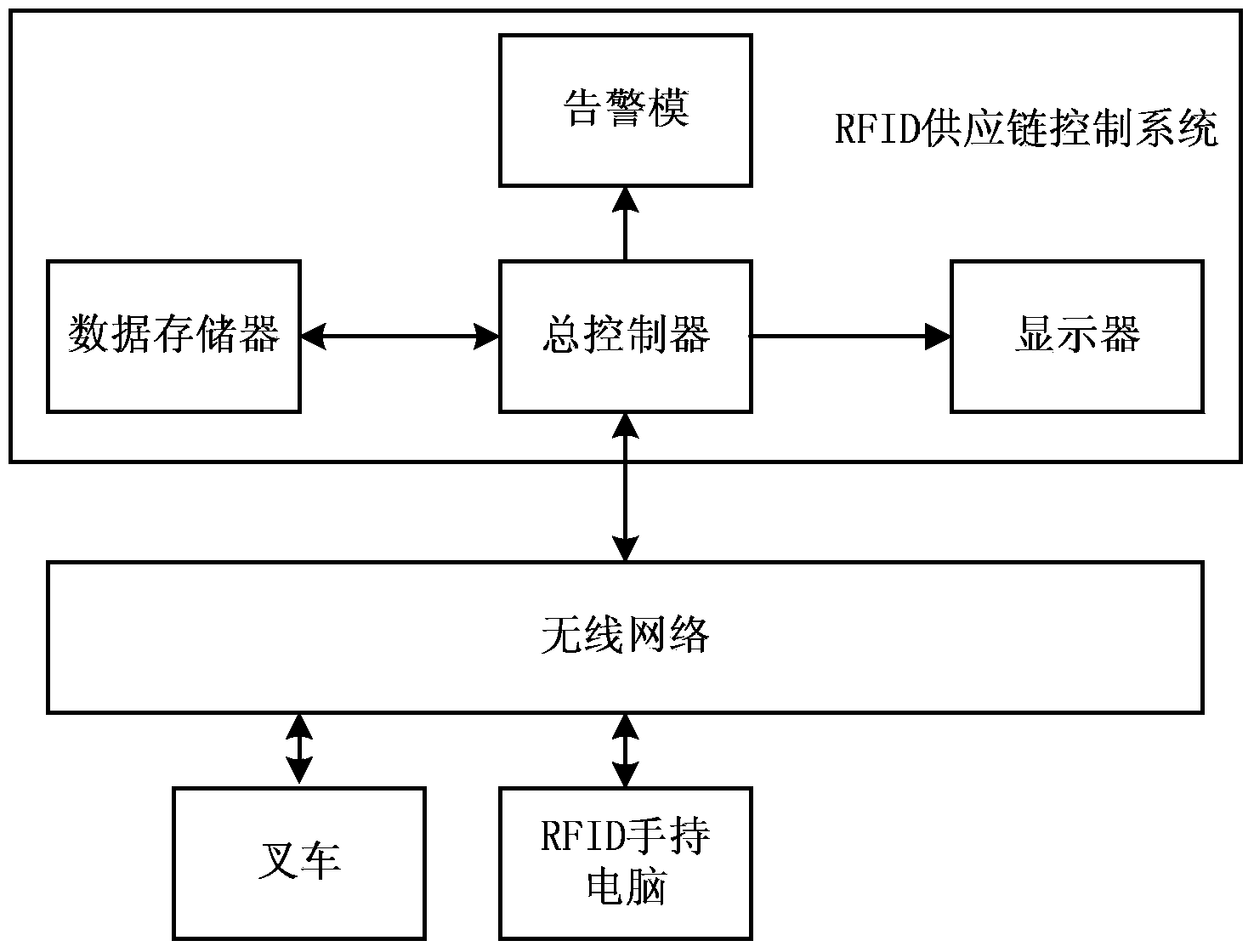

[0081] After the unloading is completed, the RFID supply chain control system automatically compares whether the total number of unloaded goods is consistent with the transfer order. If not, it will remind the forklift operators to ...

Embodiment 3

[0087] This embodiment introduces the operation process of sorting loose boards and dismantling and assembling pallets.

[0088] Warehouse workers carry RFID handheld computers to the loose board area, looking for loose boards that can be assembled. The RFID handheld computer scans the RFID pallet label of the loose board for release confirmation, and releases the association between the RFID pallet label and the barcode of the single product (single product). Warehouse workers use the RFID handheld computer to scan the barcodes of all items that need to be assembled again, and scan the RFID tray label of the new board to confirm the associated item barcode and the RFID tray label of the new board, thus completing the plattering operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com