Low-cogging-torque flux switching permanent magnet motor

A cogging torque and magnetic flux switching technology, which is applied to the static parts of the magnetic circuit, the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., can solve the problem of reducing the induced electric potential of the motor, large cogging torque, Increase the difficulty of motor processing and other issues to achieve the effect of saving consumption, reducing cogging torque and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

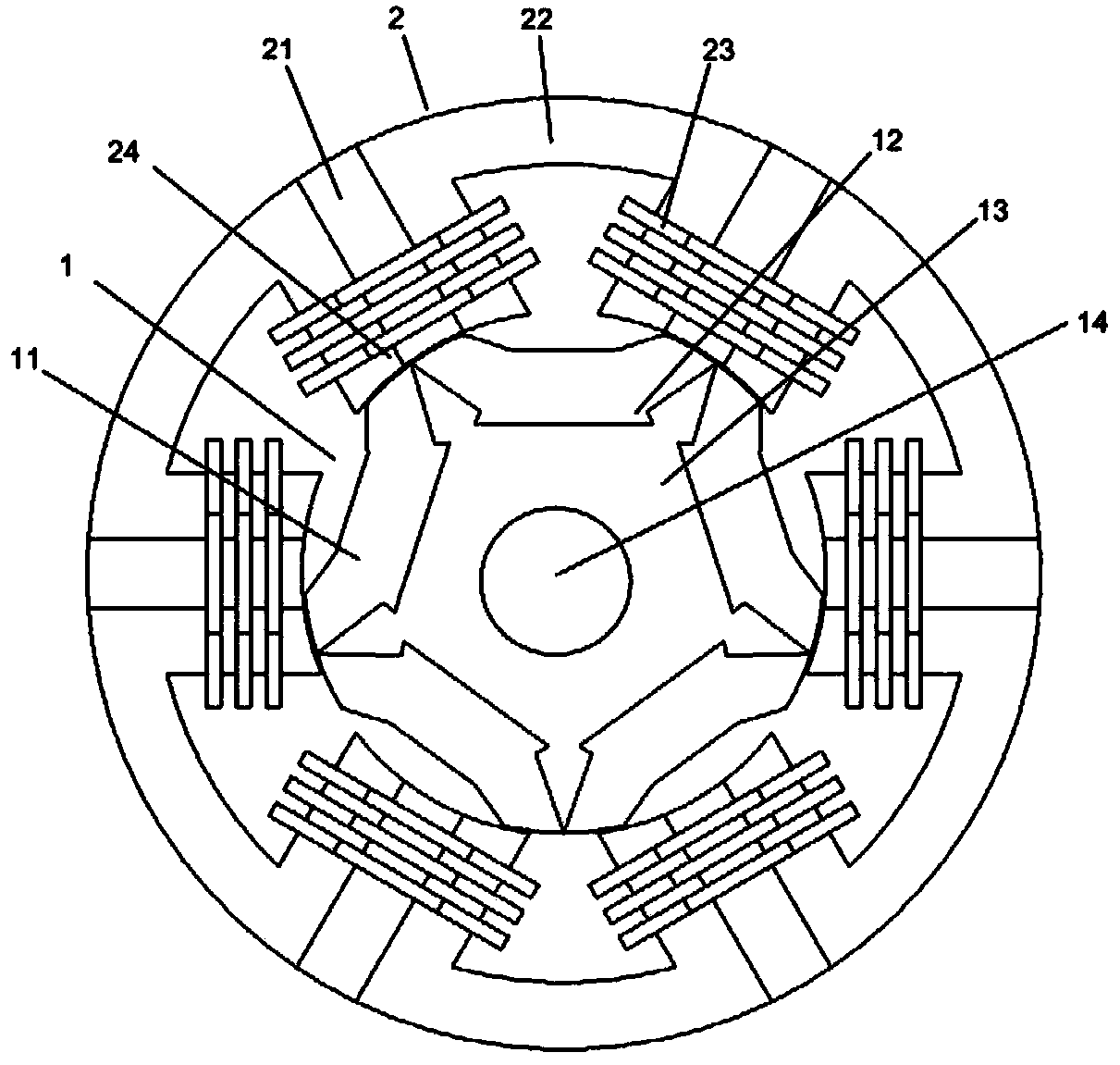

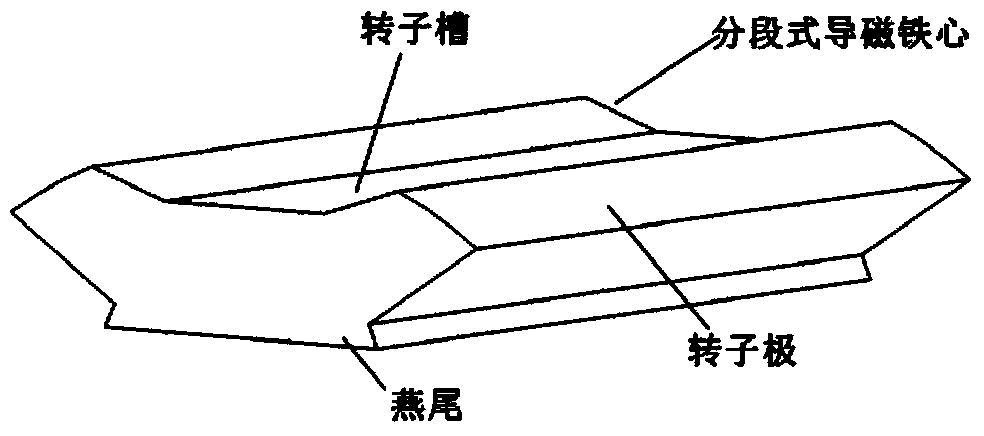

[0019] Embodiment 1: as figure 1 Shown is a cross-sectional view of a 6 / 5 extremely low cogging torque flux switching permanent magnet motor of the present invention. The 6 / 5 extremely low cogging torque flux switching permanent magnet motor includes a stator 2 with a salient pole structure and a rotor 1 with an embedded structure arranged inside the stator. The stator 2 is composed of 6 U-shaped stator cores 22 , 6 parallel permanent magnets 21 and 6 concentrated armature coils 23 . Six U-shaped stator cores 22 are evenly distributed along the circumferential direction of the stator. The stator cores are punched out of silicon steel sheets with a thickness of 0.35 mm to form stator punches, and the punches are laminated axially to form stator cores. The adjacent sides of two adjacent U-shaped stator magnetic cores 22 form a stator tooth, and a parallel permanent magnet 21 is embedded in the two adjacent sides of two adjacent U-shaped stator magnetic cores. A total of 6 para...

Embodiment 2

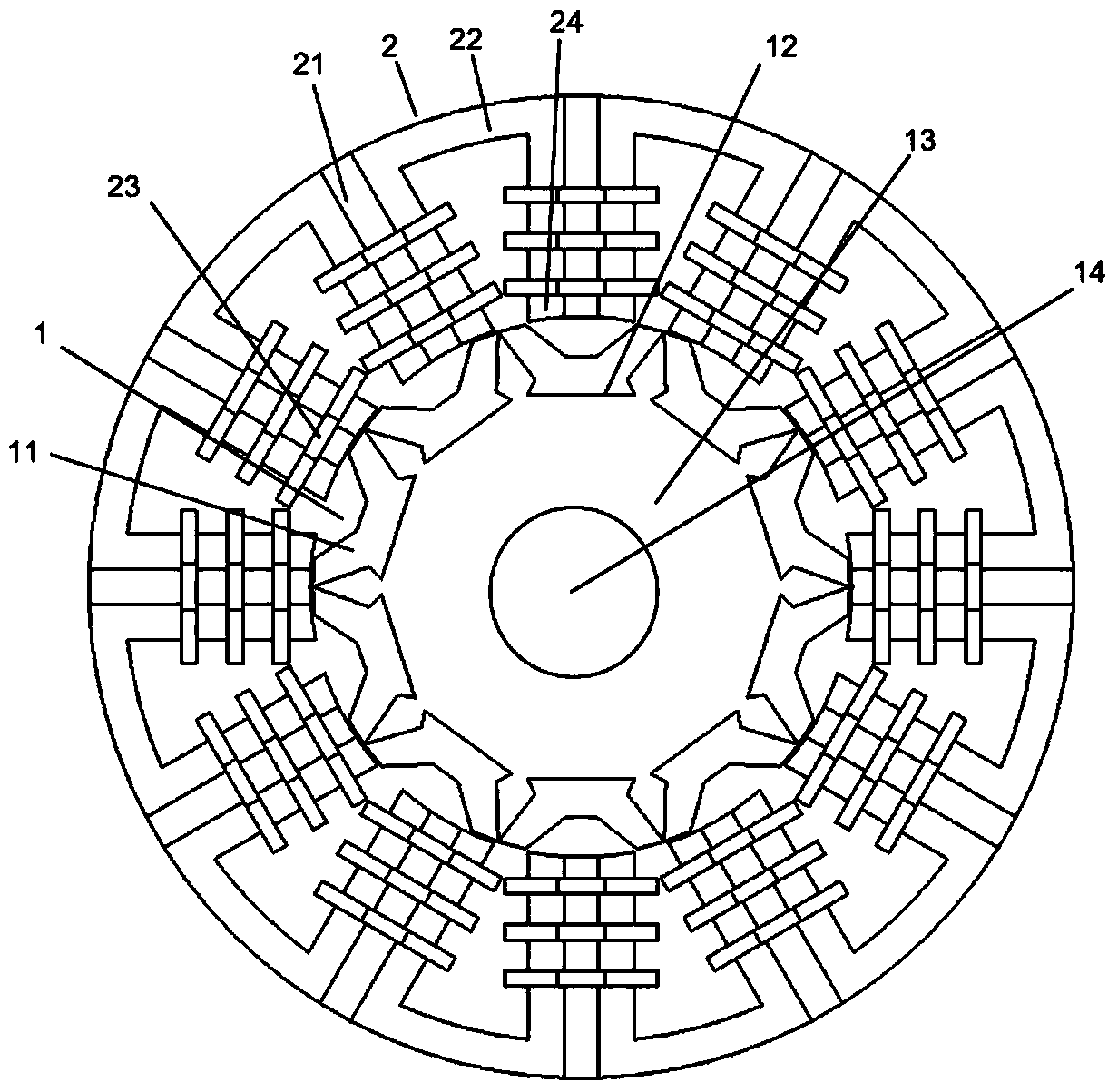

[0020] Embodiment 2: as image 3 Shown is the multiple expansion of the stator unit and the rotor unit of the motor to obtain the sectional view of the 12 / 10 extremely low cogging torque magnetic flux switching permanent magnet motor of the present invention. The motor stator 2 is composed of 12 U-shaped stator cores 22 , 12 parallel permanent magnets 21 and 12 concentrated armature coils 23 . The embedded structure rotor 1 is composed of 10 embedded U-shaped rotor cores 11 , rotor blocks 13 and rotor shafts 14 . The structures of the stator and the rotor are the same as those of the 6 / 5 extremely low cogging torque flux switching permanent magnet motor in Embodiment 1.

[0021] The operation principle of the low cogging torque permanent magnet motor proposed by the present invention is consistent with that of the traditional doubly salient flux switching permanent magnet motor. As the rotor position changes, the amplitude and polarity of the stator flux linkage and induced p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com