Motor spindle vibration active control apparatus

An electric spindle and bearing technology, applied in electromechanical devices, electric components, electrical components, etc., can solve the problem of rare active vibration control, and achieve the effects of easy assembly and maintenance, improved processing quality, and compact device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

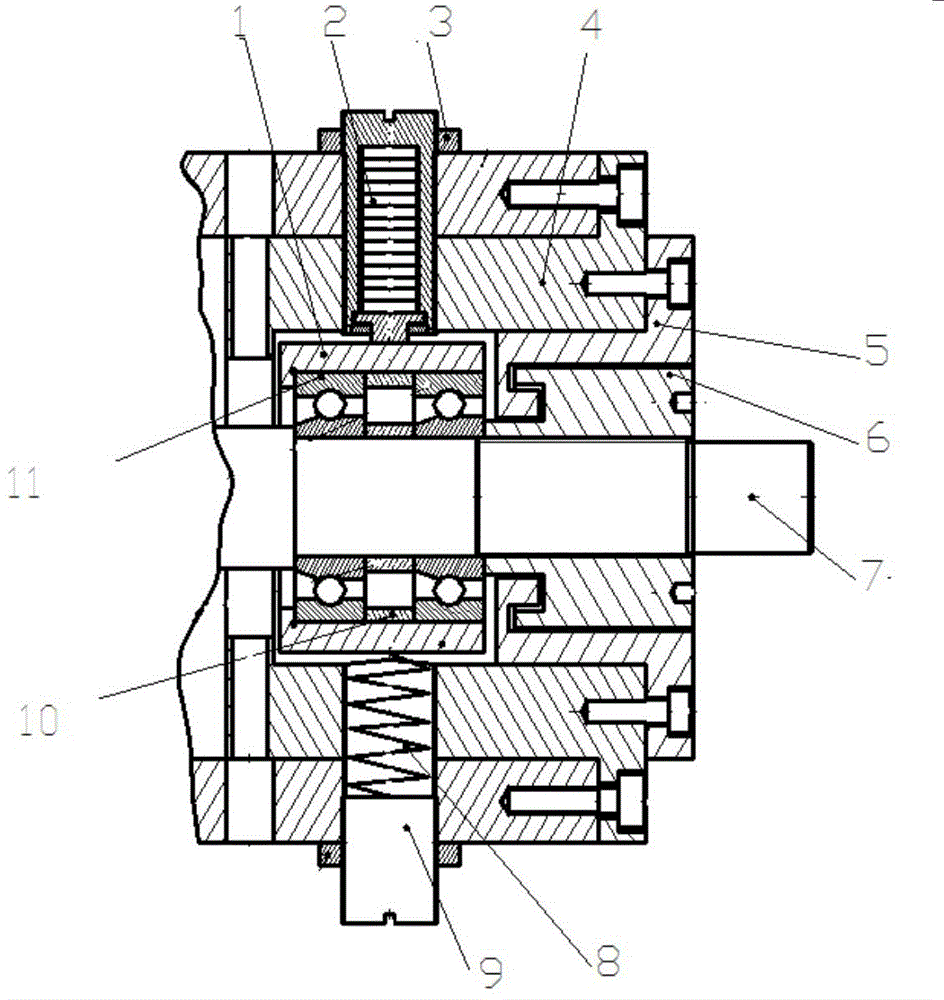

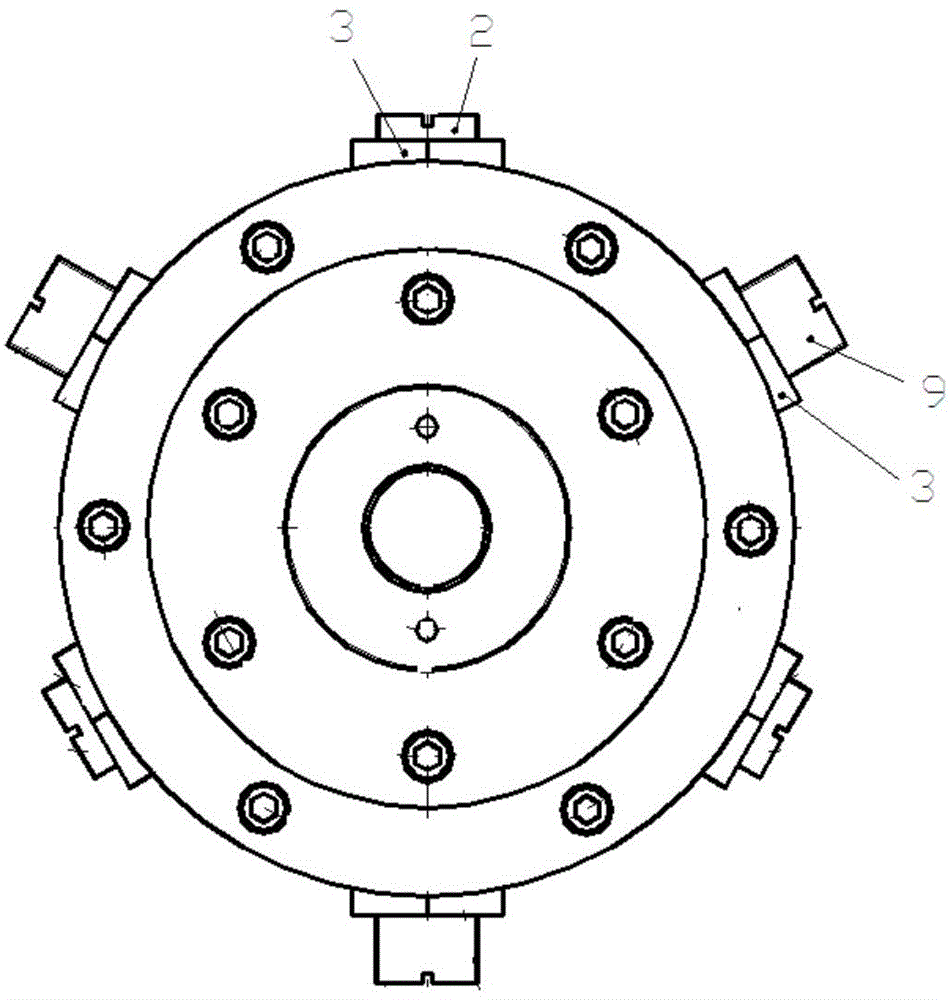

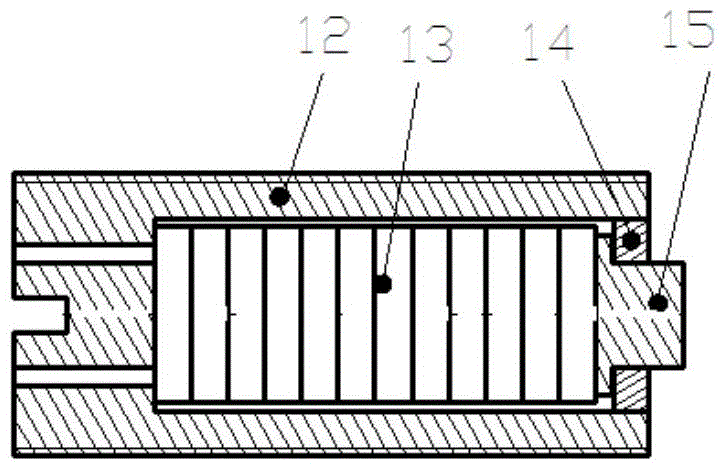

[0019] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 right view of the image 3 Schematic diagram of the structure of the piezoelectric ceramic driver. As shown in the figure, the active vibration control device for the electric spindle in this embodiment includes a bearing assembly installed on the electric spindle and an adjustable positioning assembly for adjusting the radial positioning of the bearing assembly.

[0020] In this embodiment, the adjustable positioning assembly includes at least two sets of positioning combinations composed of piezoelectric ceramic actuators 2 and elastic elements. The piezoelectric ceramic actuators 2 and corresponding elastic elements are arranged on both radial sides of the bearing assembly; The electroceramic driver 2 and the elastic element are evenly distributed along the circumference of the bearing assembly. The piezoelectric ceramic driver 2 includes a housing 12, a piezoelectric st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com