Method for online computing motor optimal operating point

A calculation method and technology of working points, which are applied in the control of generators, motor generators, electronic commutation motor control, etc., can solve the problems of complex implementation, large amount of calculation, and time-varying motor parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

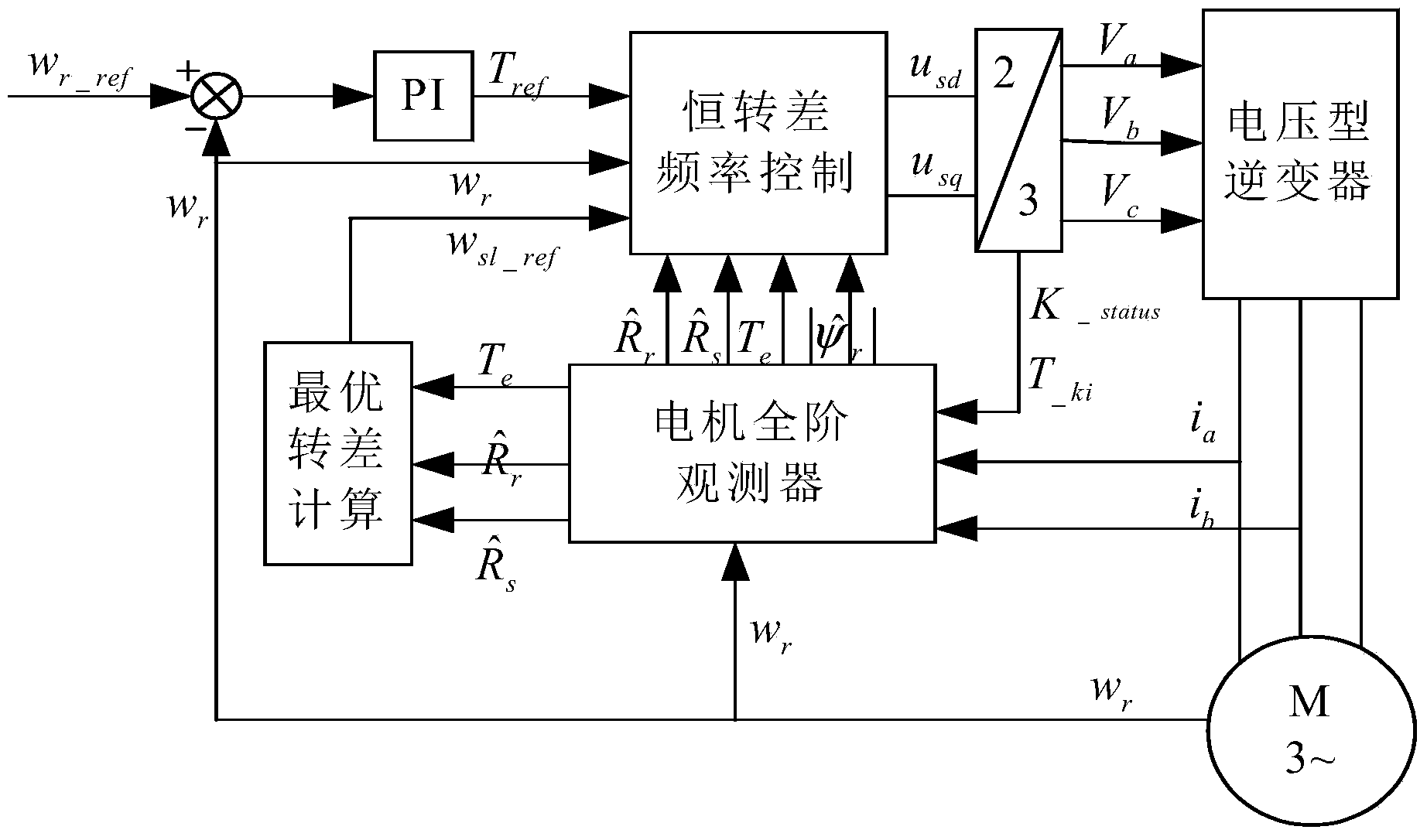

[0030] An online calculation method for the best working point of the motor of the present invention combines the idea of efficiency optimization control based on model loss and the idea of minimum stator current control, and obtains the corresponding slip frequency when the asynchronous motor is at the best working point; and Aiming at the time-varying characteristics of motor parameters, a set of optimal slip frequency calculation methods based on motor model prediction is established, and a complete set of online calculation methods for the optimal operating point of asynchronous motors is formed.

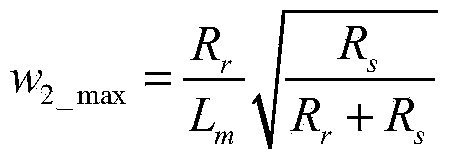

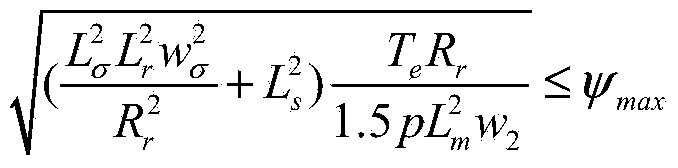

[0031] In the present invention, the derivation process of the corresponding slip frequency (that is, the optimal slip frequency) when the asynchronous motor is at the optimal operating point is:

[0032] In the synchronous rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com