Glass plate for tempering

A glass plate and glass technology, applied in glass tempering, glass manufacturing equipment, transportation and packaging, etc., can solve the problems of small linear thermal expansion rate, large linear thermal expansion rate, difficult to strengthen, etc., and achieve excellent scratch resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

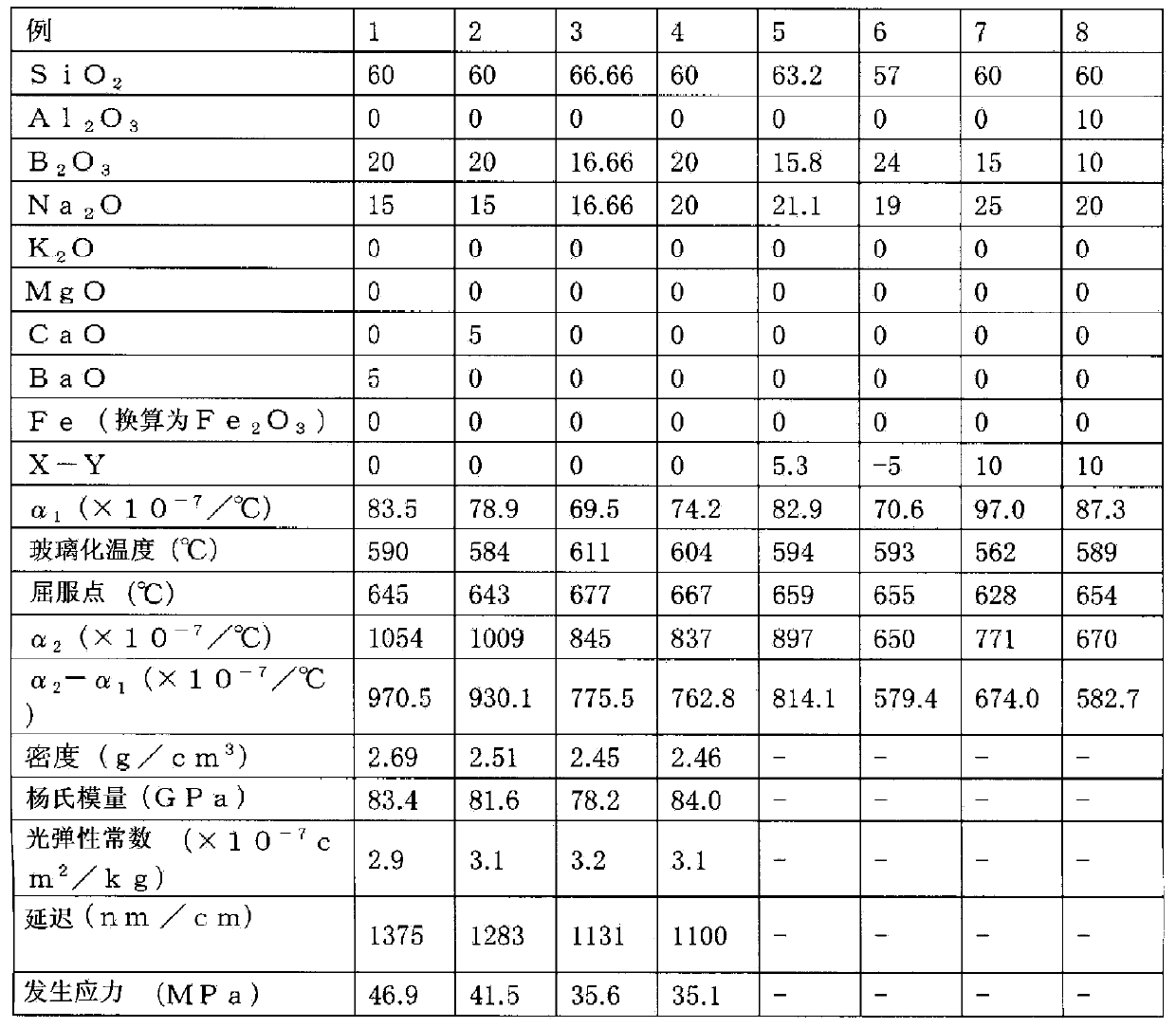

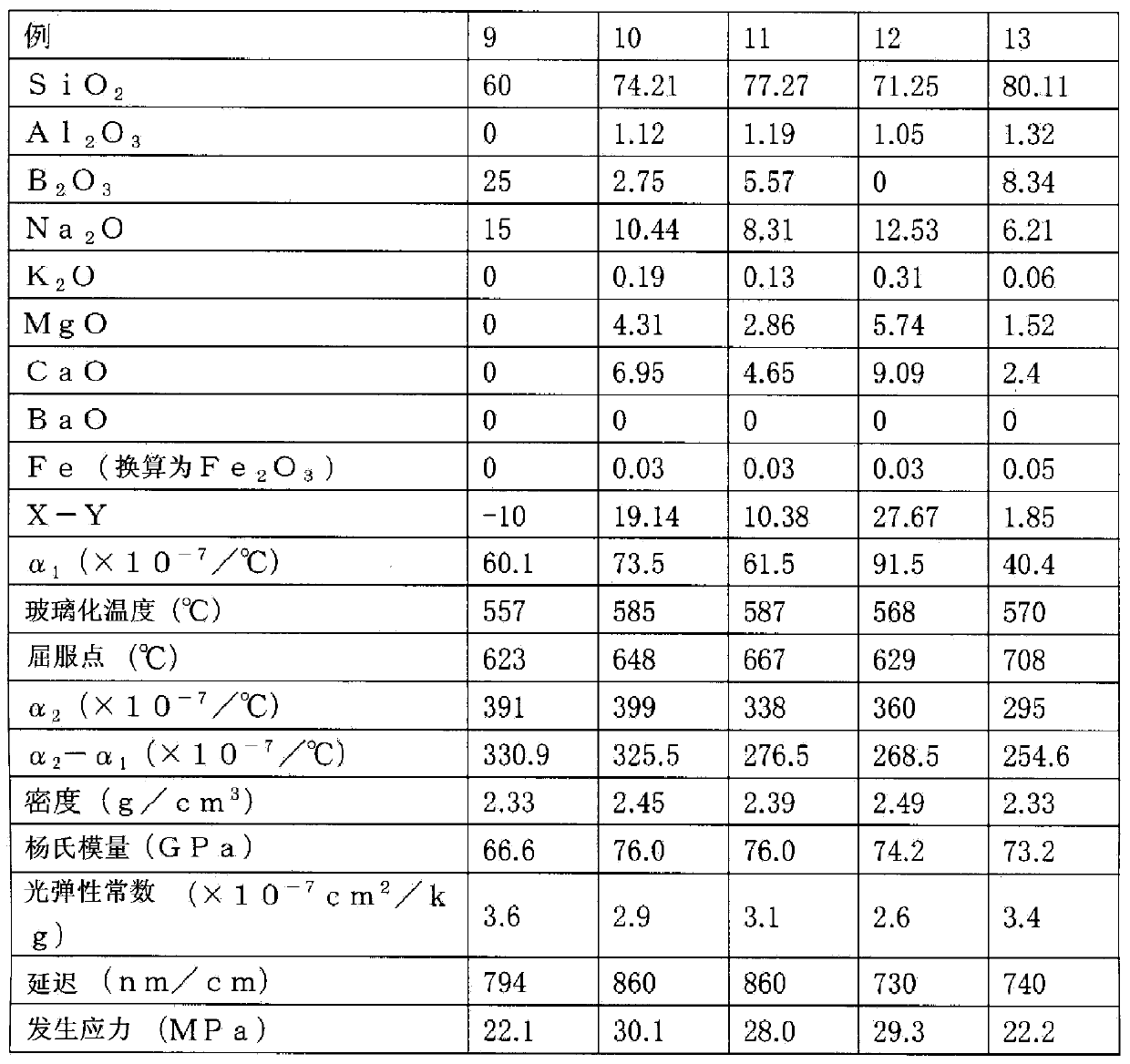

[0061] Hereinafter, the present invention will be described in more detail by way of examples, but the present invention is not limited to these examples.

[0062] According to the conditions of the glass composition (Example of the present invention) represented by mol% in Table 1, or the conditions of the glass composition (Comparative Example of the present invention) represented by mol% in Table 2, the oxide, hydroxide Generally used glass raw materials such as substances, carbonates, and nitrates are weighed and mixed under the condition that the glass reaches 500 g. Then, pour the mixture into a platinum crucible, put it into a resistance heating electric furnace at 1450°C, melt it for 1 hour, pour it into a mold, immerse it in a container filled with water for water quenching (Japanese: water castor), and break it into 15mm The following fragments. Next, pour the pieces into a platinum crucible again, melt them for 2 hours, pour them into a mold after defoaming, keep t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com