Method for producing glufosinate P free acid

A manufacturing method and glufosinate-ammonium technology are applied in the manufacturing field of glufosinate-ammonium P free acid, which can solve the problems of high hygroscopicity and complicated post-processing procedures, and achieve the effect of low hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

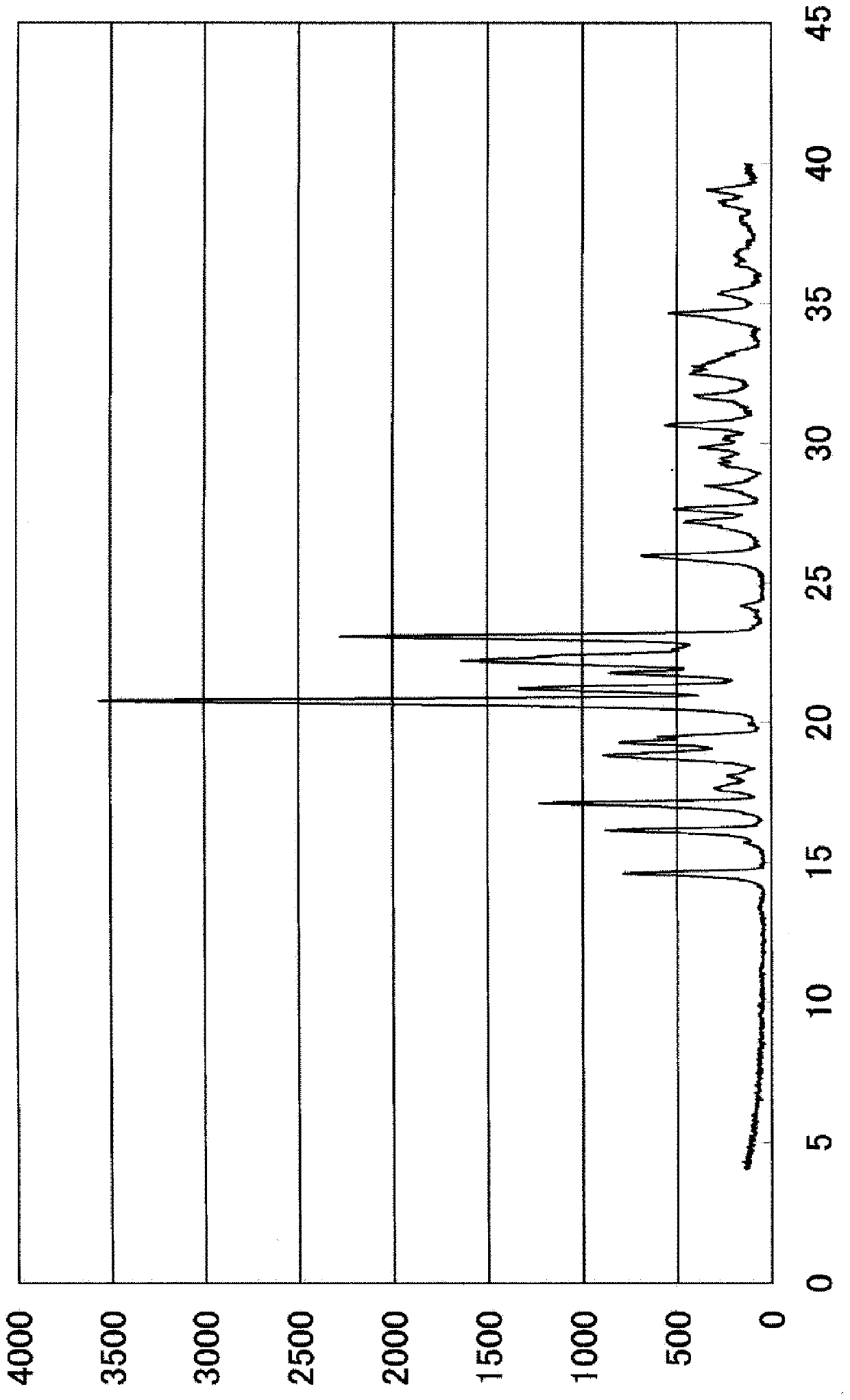

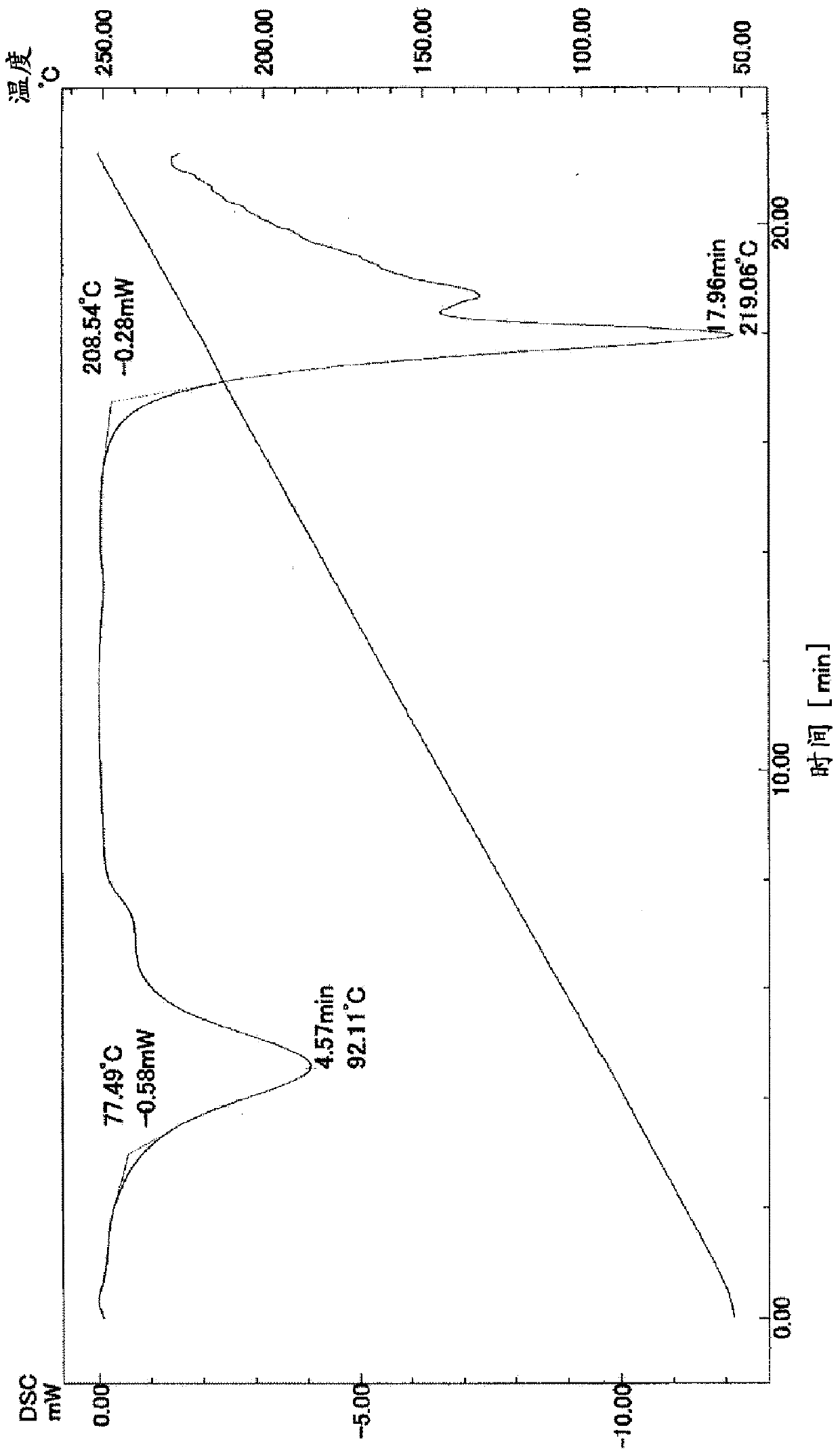

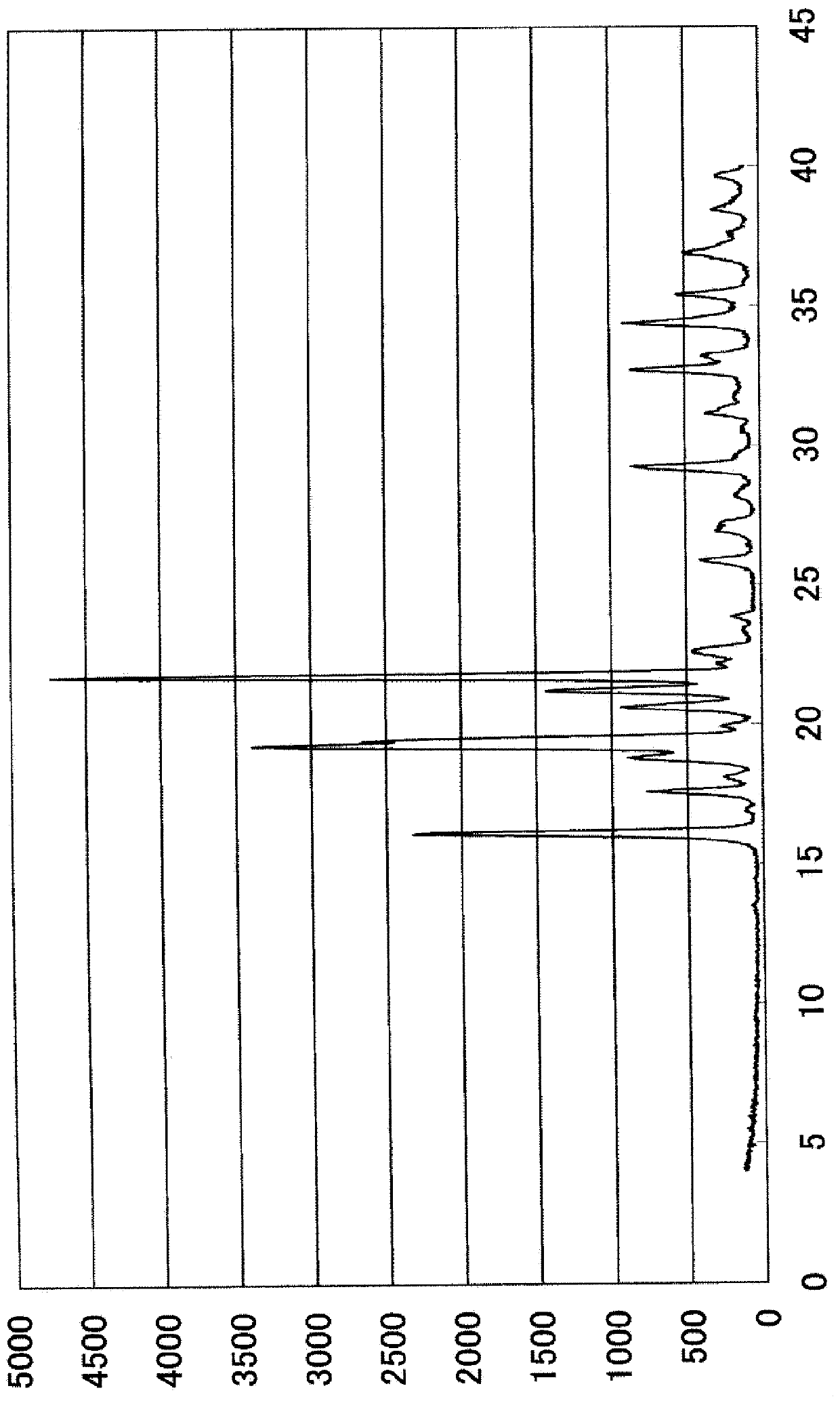

Image

Examples

Embodiment 1

[0079] Embodiment 1: the manufacture of glufosinate-ammonium P free acid

[0080] 50 mmol of glufosinate-ammonium P hydrochloride was dissolved in 10 mL of water and 90 mL of methanol, and 25 mL of methanol in which 1 N of sodium hydroxide was dissolved was added thereto. The seed crystal obtained in Reference Example 2 was added, stirred at room temperature for 15 minutes, then cooled with ice and stirred for 3 hours and 30 minutes, and the precipitated crystals were collected by filtration. This was vacuum-dried to obtain 9.35 g of the title compound (recovery rate: 95.9%, purity: 91.7%).

Embodiment 2

[0081] Embodiment 2: the manufacture of glufosinate-ammonium P free acid

[0082] 50 mmol of glufosinate-ammonium P hydrochloride was dissolved in 17 mL of water, and 4.17 g of water in which 1 N of sodium hydroxide was dissolved was added thereto. 60 mL of methanol was added thereto, and the seed crystal obtained in Reference Example 2 was added, stirred at room temperature for 15 minutes, then cooled with ice and stirred for 3 hours and 30 minutes, and the precipitated crystals were filtered out. This was vacuum-dried to obtain 9.09 g of the title compound (recovery rate: 92.4%, purity: 92.0%).

Embodiment 3

[0083] Embodiment 3: the manufacture of glufosinate-ammonium P free acid

[0084] 50 mmol of glufosinate-ammonium P hydrochloride was dissolved in 20 mL of water and 180 mL of methanol, and 1 N of sodium hydroxide was added thereto. The seed crystal obtained in Reference Example 2 was added, stirred at room temperature for 15 minutes, then cooled with ice and stirred for 3 hours and 30 minutes, and the precipitated crystals were collected by filtration. This was vacuum-dried to obtain 9.09 g of the title compound (recovery rate: 91.3%, purity: 98.8%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com