Pattern forming method, electron beam-sensitive or extreme ultraviolet-sensitive composition, resist film, method for manufacturing electronic device using the same, and electronic device

A technology for extreme ultraviolet rays and electronic devices, applied in the fields of pattern formation, electron beam sensitive or extreme ultraviolet sensitive compositions, resist films, the use of which to manufacture electronic devices and electronic devices, capable of solving problems such as poor resolution of pattern outlines , to achieve the effect of high resolution, high sensitivity, high line width roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0947]

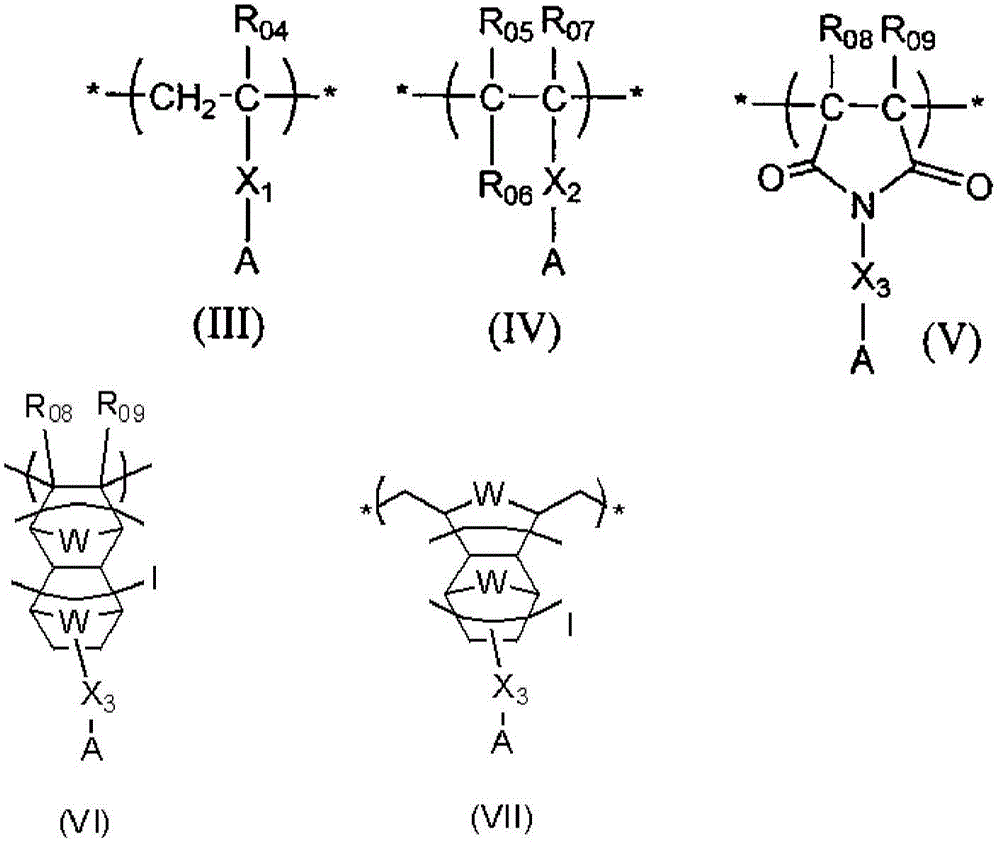

[0948] Resins (A-1) to (A-24), (RA-1) and (RA-2) shown below were synthesized as follows. The weight average molecular weight (Mw) and polydispersity (Mw / Mn) of each resin are shown below. Also, the composition ratio of each repeating unit of the resin is shown in molar ratio.

[0949]

[0950]

[0951]

[0952]

[0953]

Synthetic example 1

[0954] [Synthesis Example 1: Resin (A-1)]

[0955] In a nitrogen flow, 160 g of cyclohexanone was charged into a three-necked flask and heated at 80° C. (solvent 1). Subsequently, Monomer-A1 (13.58 g), Monomer-1 (23.11 g), Monomer-2 (12.48 g) and Monomer-3 (31.35 g) shown below were dissolved in cyclohexanone (297 g) to prepare a monomer solution. Further, a solution obtained by adding and dissolving a polymerization initiator V-601 (manufactured by Wako Pure Chemical Industries, Ltd.) at a rate of 6.4 mol% based on the monomer was added dropwise to Solvent 1 over 6 hours. After the dropwise addition was completed, the solution was further reacted at 80° C. for 2 hours. The reaction solution was cooled and then added dropwise to a mixed solvent of 3,000 g of heptane / 750 g of ethyl acetate, and the precipitated powder was collected by filtration and dried to obtain 62 g of Resin (A-1). The obtained resin (A-1) had a weight average molecular weight of 10,500, a polydispersity...

Embodiment 1 to 24 and comparative example 1 and 2

[0982] [Examples 1 to 24 and Comparative Examples 1 and 2 (electron beam (EB) exposure)]

[0983] (1) Preparation of Coating Solution of Electron Beam Sensitive or Extreme Ultraviolet Sensitive Resin Composition, and Coating

[0984] Coating solution compositions according to the formulations shown in the following table were microfiltered through a membrane filter having a pore size of 0.1 μm to obtain electron beam-sensitive or extreme ultraviolet-sensitive resin composition (resist composition) solutions.

[0985] This electron beam-sensitive or extreme ultraviolet-sensitive resin composition solution was coated on a 6-inch Si wafer previously treated with hexamethyldisilazane (HMDS) by using a spin coater Mark8 (manufactured by Tokyo Electron Ltd.) and dried on a hot plate at 100° C. for 60 seconds to obtain a resist film with a thickness of 50 nm.

[0986] (2) EB exposure and development

[0987] The resist film-coated wafer obtained in (1) above was subjected to patter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com