Rolling bar type drying device

A drying device and roller-type technology, which is applied in the field of dryers, can solve the problem of high sugar content in fruits, achieve the effects of increasing production, improving automation, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

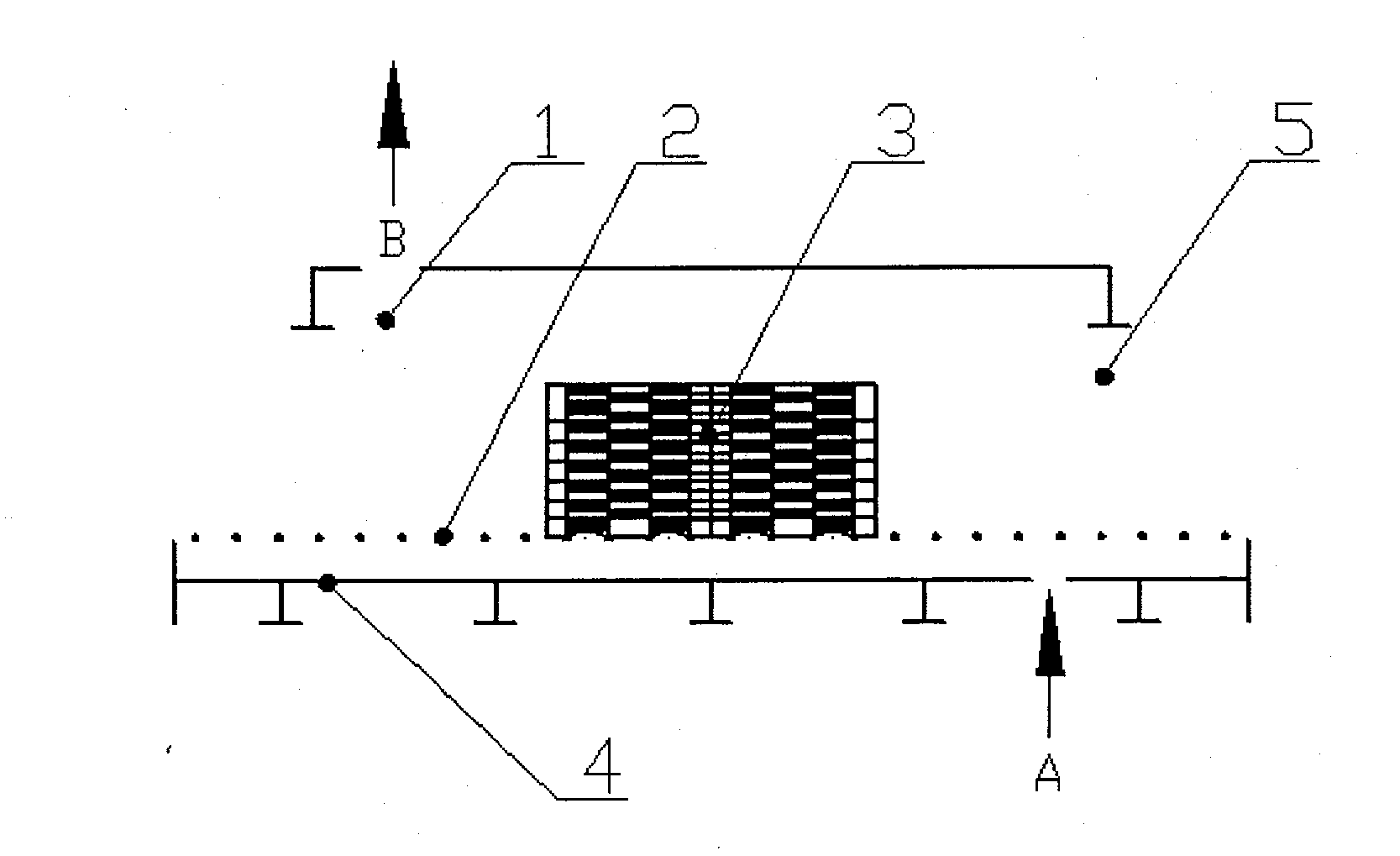

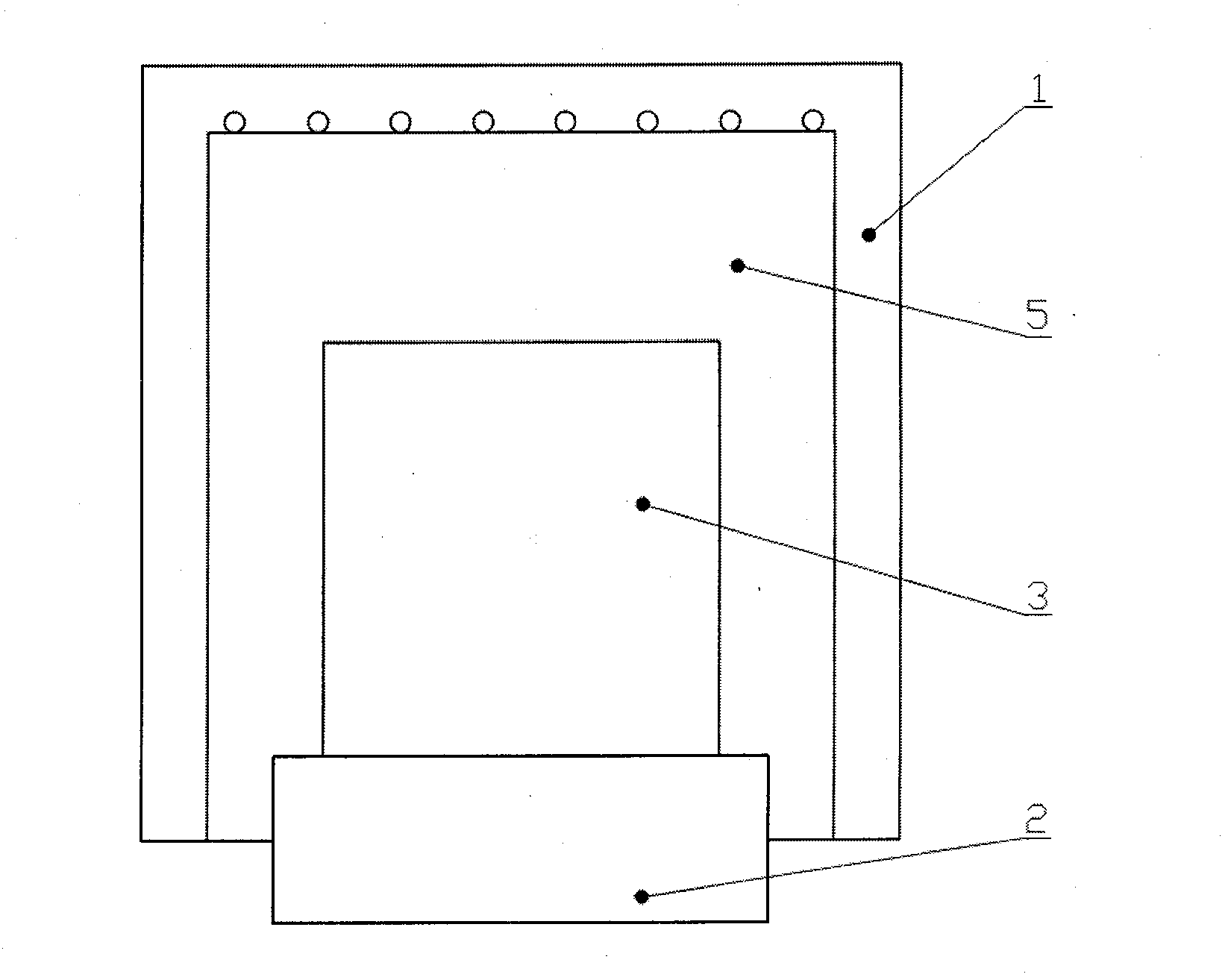

[0012] A roller-type fruit dryer, which adopts a horizontal drying chamber (1), has a continuous material conveying system and a hot air circulation system in the chamber, and the material conveying system is a chain-driven horizontal continuous roller (2), and the roller (2 ) is installed on the frame (4), and the multi-layer material rack (3) for holding the fruit is placed on the roller bar (2); when the fruit is dried, the fruit is placed on the multi-layer material rack (3) ), the horizontal continuous roller driven by the chain is driven by the reducer to carry out material transmission, and the multi-layer material rack (3) containing the fruit enters the horizontal drying from the inlet (5) along with the continuous transmission of the roller (2). Drying room (1), during the material transfer process, the hot air circulation system heats the air in the machine through the heater, and enters the horizontal drying room (1) from A, and the circulating fan generates a circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com