Two-degree-of-freedom modularized artificial hand thumb with moment of force, position and touch perception function

A technology of tactile perception and degree of freedom, applied in the field of prosthetic thumb, can solve the problems of low modularity, poor alignment, lack of tactile perception function, etc., to achieve the effect of preventing sliding, convenient disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

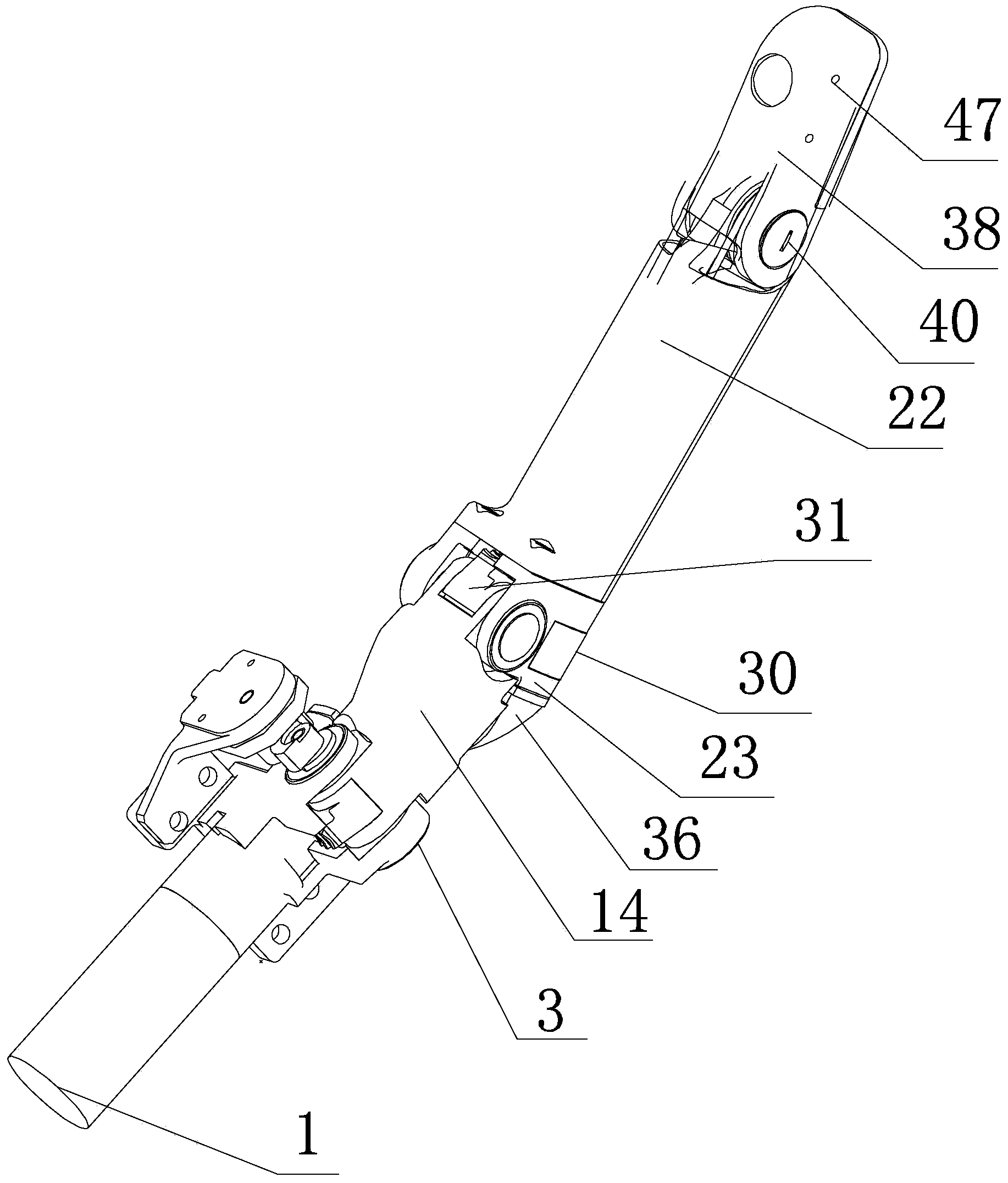

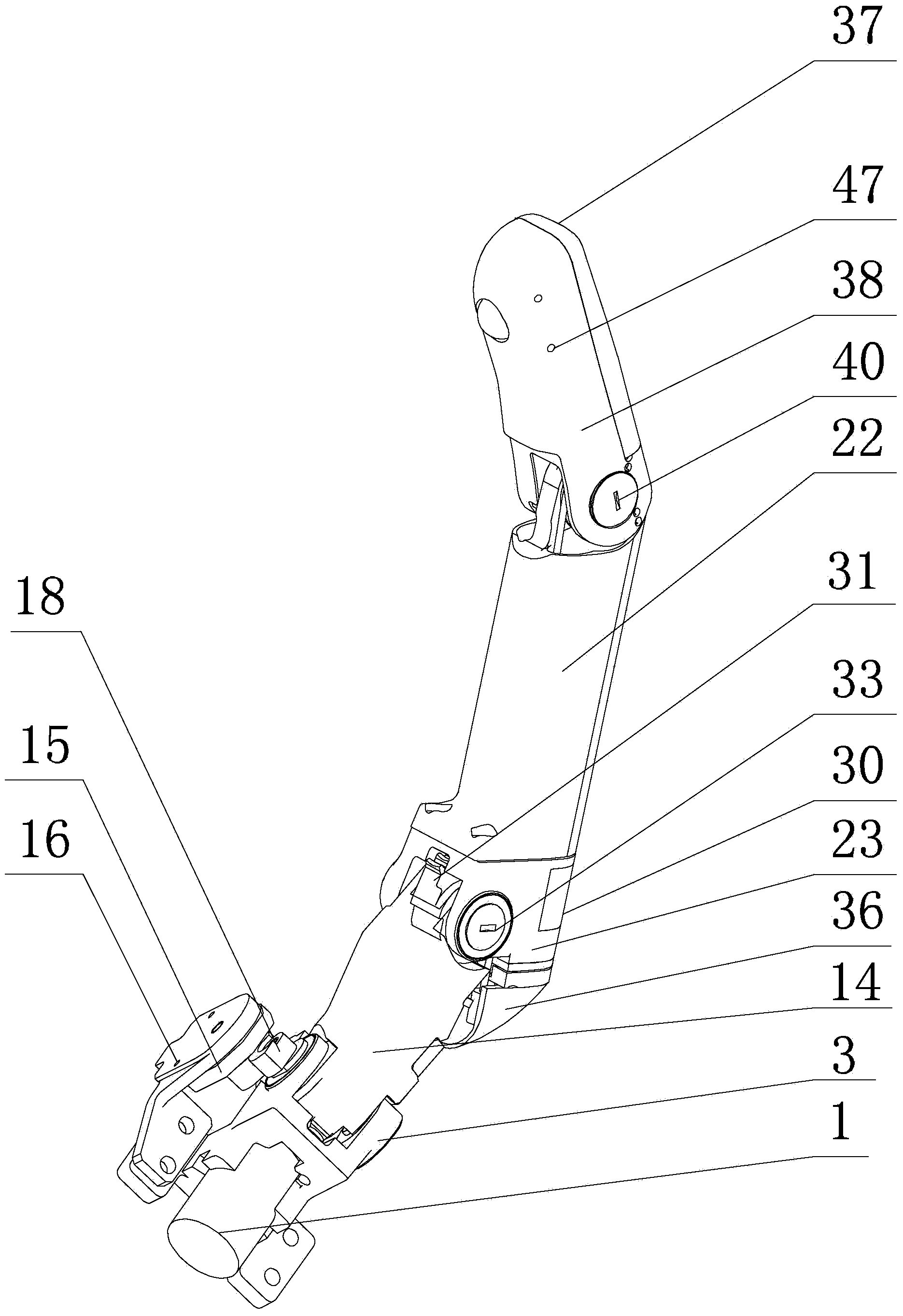

[0016] Specific implementation mode one: as Figure 1-10 As shown, the two-degree-of-freedom modular prosthetic thumb in this embodiment includes a metacarpal knuckle, a proximal knuckle and a distal knuckle, and the metacarpal knuckle includes a first motor 1, a first reducer 2, Fixed frame 3, first worm 4, first worm shaft 7, first end cover 8, first worm gear 10, first worm gear cover 11, metacarpal joint shaft 12, metacarpal joint screw 13, metacarpal base 14, position sensor 15. Sensor fixing frame 16, first plastic transmission gear 17, second plastic transmission gear 18 and transmission shaft 19;

[0017] The output end of the first motor 1 is connected to the input end of the first reducer 2, the first reducer 2 is fixed on the fixed frame 3, the fixed frame 3 is fixedly connected with the palm, and one end of the first worm 4 is connected to the first The output shaft of the reducer 2 is connected, the other end of the first worm 4 is provided with a first worm shaf...

specific Embodiment approach 2

[0024] Embodiment 2: In this embodiment, the left side of the first plastic gear 17 is processed with an integrated “D” shaped round platform, and the “D” shaped round platform is located in the inner hole of the position sensor 15 . With such a design, the first plastic gear 17 can rotate together with the inner hole of the position sensor 15, so as to realize the relative movement between the inner hole of the position sensor and the shell, and ensure its normal operation. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

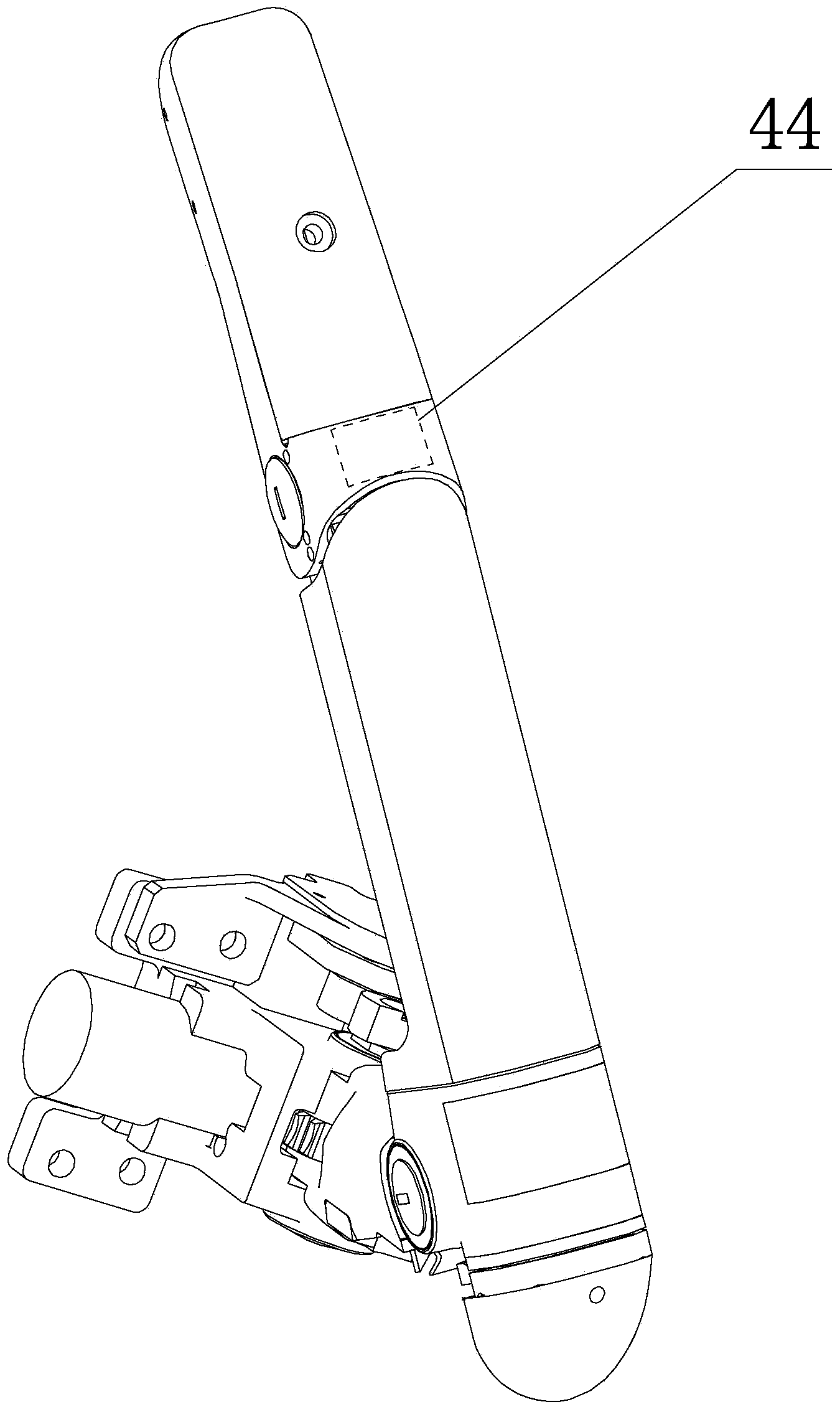

[0025] Specific implementation mode three: as Figure 4 As shown, the metacarpal phalanx in this embodiment also includes a first worm washer 5 and a first plastic sleeve 6, and one end of the first worm 4 is sequentially fitted with a first worm washer 5 and a first plastic sleeve The barrel 6 , the first worm spacer 5 and the first plastic sleeve 6 are located between the first reducer 2 and the fixed frame 3 . Such a design can not only effectively resist the large axial load of the first worm 4, but also can reduce the loss of driving force by properly selecting the materials of the two to determine an appropriate coefficient of friction. The first worm washer 5 and the first plastic sleeve 6 can also be replaced by thrust bearings, although this can better reduce friction loss, but the size of the fingers will be relatively increased. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com