A method for detecting and correcting the positioning accuracy of the rotary axis of a five-axis machine tool

A positioning accuracy and rotation axis technology, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, other manufacturing equipment/tools, etc., can solve the problem that fixtures cannot be used universally, inspection and correction are difficult, and rotation axis positioning accuracy cannot be corrected and compensated and other problems, to achieve the effect of simple and fast correction and compensation, saving inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

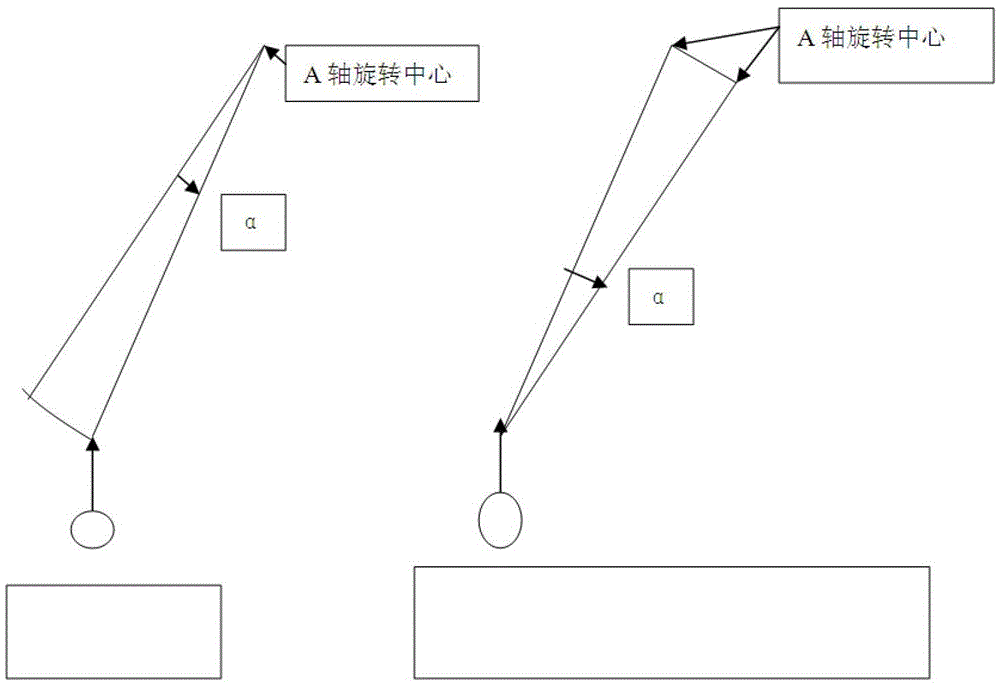

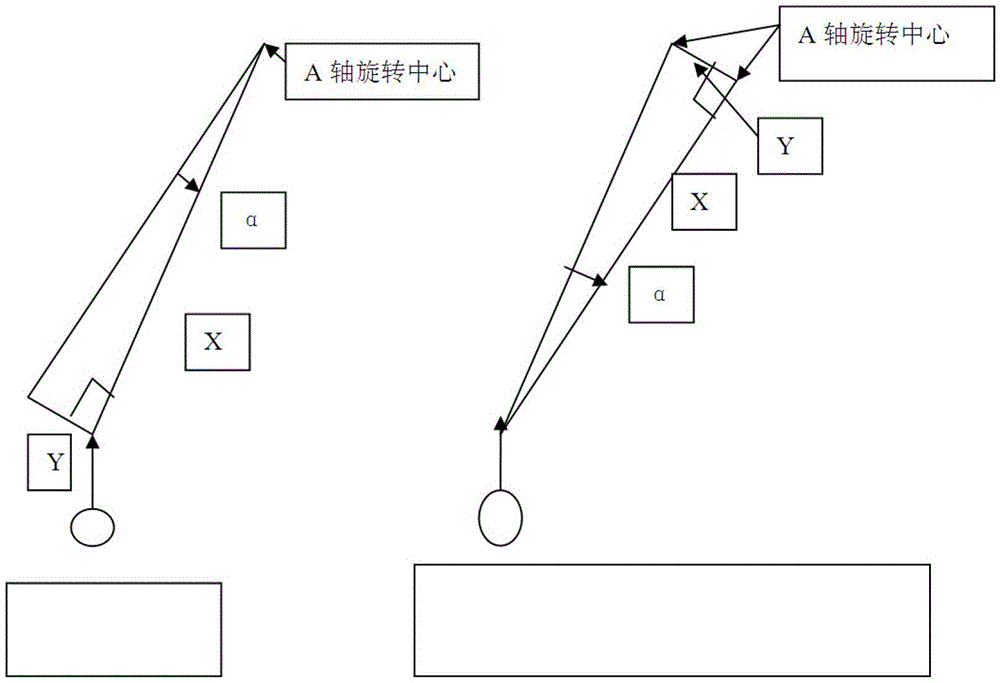

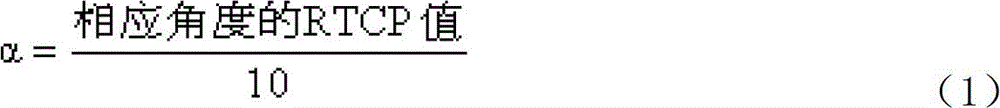

[0046] Embodiment 1, correcting the positioning accuracy of the A-axis of a five-axis vertical AC-axis machine tool. Proceed as follows:

[0047] Step 1: Detect and correct the vertical precision between the spindle of the machine tool and the X-axis, and the precision is 0.02 / 300mm.

[0048] Step 2, detecting and correcting the vertical accuracy of the spindle of the machine tool and the Y-axis, with an accuracy of 0.02 / 300mm.

[0049] Step 3: Detect and correct the perpendicularity between the rotation of the C-axis and the X-axis, with an accuracy of 0.02 / 600mm.

[0050]Step 4: Detect and correct the perpendicularity between the C-axis rotation and the Y-axis, with an accuracy of 0.02 / 600mm.

[0051] Step 5: Detect and correct the zero position of the rotary coordinates of the machine tool, so that the pointer of the dial gauge is pressed against the straight rod, the Z axis of the machine tool moves up and down by 250mm, and the pointer of the gauge fluctuates within 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com