Method for venting of hydraulic brake system of vehicle and brake system controller

A brake system and hydraulic brake technology, applied in the direction of brake safety system, brake, pump/compressor arrangement, etc., can solve the problems of increasing the pedal operation stroke, interference, and unrealistic necessary steps, so as to reduce residual gas volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

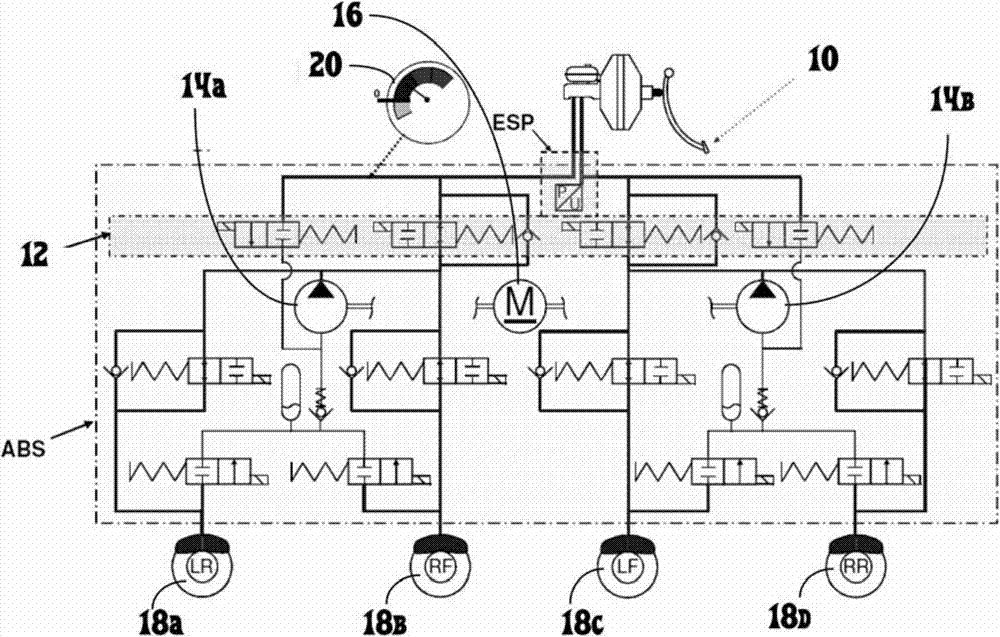

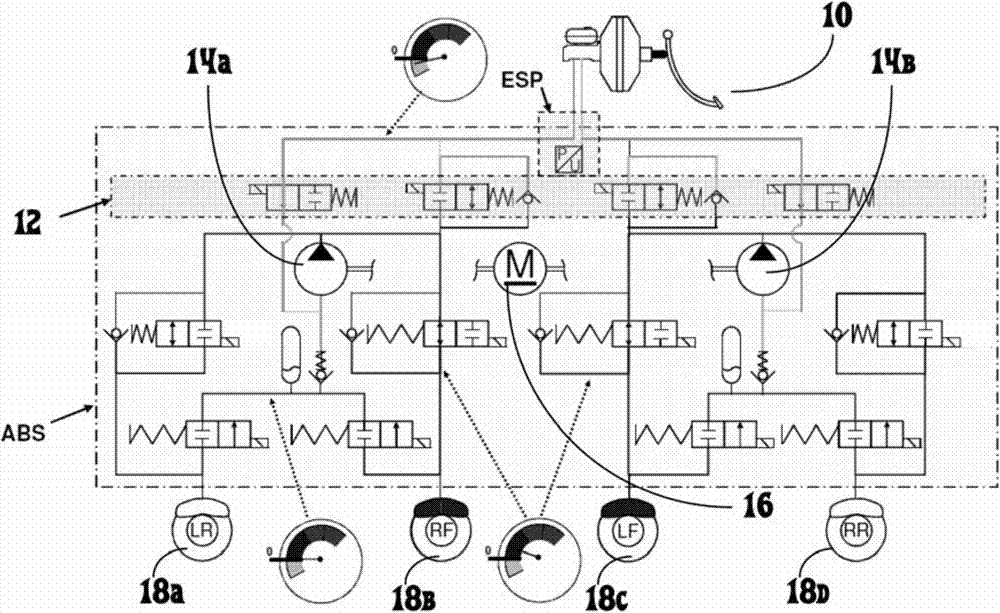

[0029] figure 1 Schematic showing the hydraulic braking system (service brakes) of a car with ABS and ESC. The braking system described is shown as an example only; the invention can be used in many different braking system configurations. According to legal regulations, two mutually independent brake circuits are provided, each brake circuit providing, in the exemplary embodiment, diagonally opposite brakes 18a to 18d in an X-shaped configuration. On the one hand, the brakes can be actuated using the brake pedal 10 , which, in a known manner, applies brake pressure to the two brake circuits independently of one another via the brake booster and the tandem master cylinder. figure 1 Lines thus affected by pressure are highlighted with thicker lines. The resulting pressure is indicated by a symbolic pressure gauge 20 and, in the case of the unit in question with "ESP", also measured by a pressure sensor (pressure / voltage converter).

[0030] In order to perform the ABS functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com