Multistage belt conveyor PLC control system based on touch screen

A control system and touch screen technology, applied in the field of PLC control system, can solve the problems of high safety interlock requirements, deviation and chute blockage, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

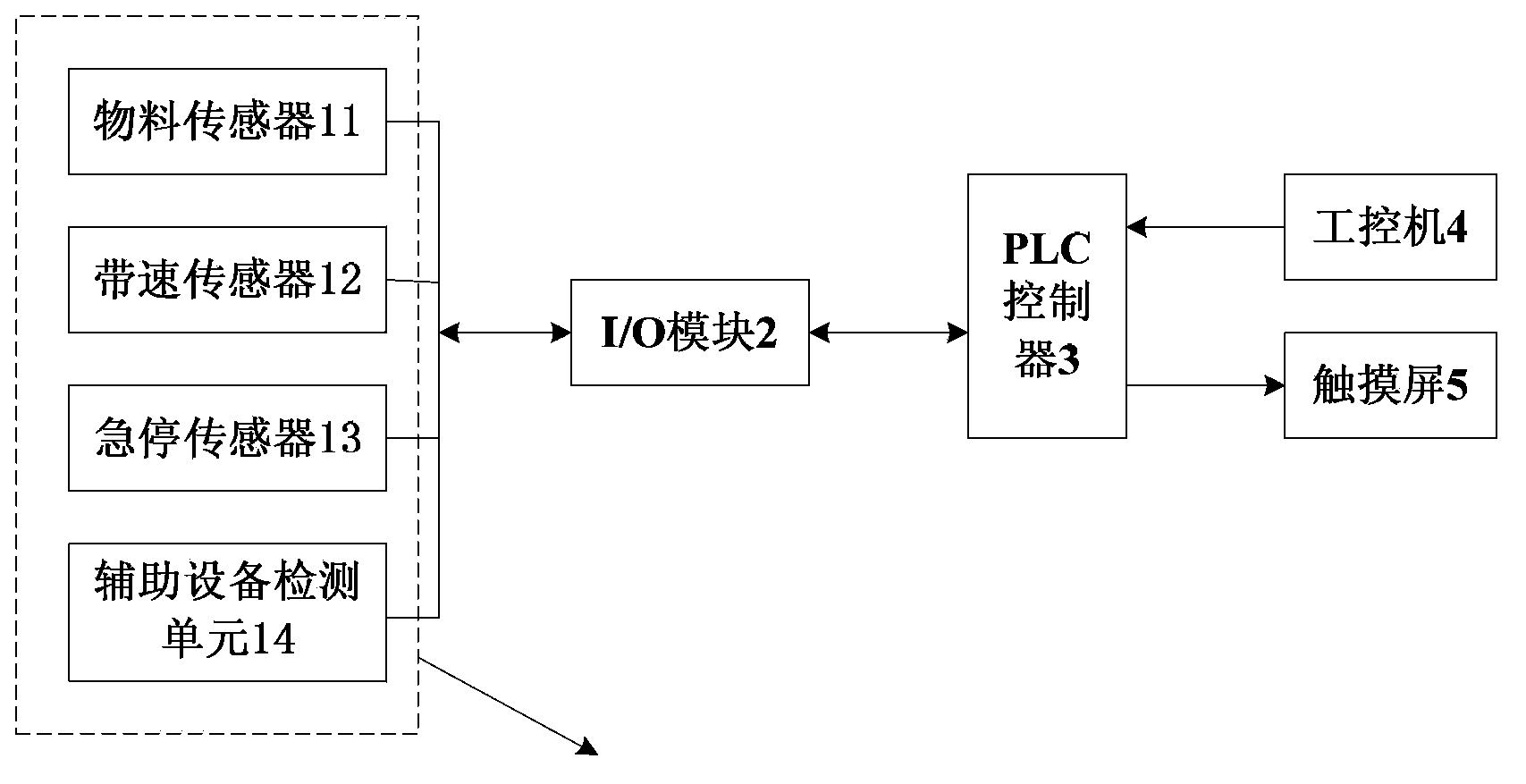

[0016] Such as figure 1 Shown is a multi-stage belt conveyor PLC control system based on a touch screen, comprising an industrial computer 4, the industrial computer 4 is electrically connected to a touch screen 5, the output of the industrial computer 4 is connected to a PLC controller 3, and the PLC The controller 3 communicates with the detection device 1 through the I / O module 2 ; the output end of the PLC controller 3 is connected with the touch screen 5 . The detection device 1 includes a material sensor 11 , a belt speed sensor 12 and an emergency stop sensor 13 arranged on the belt conveyor, and an auxiliary equipment detection unit 14 for the belt conveyor.

Embodiment 2

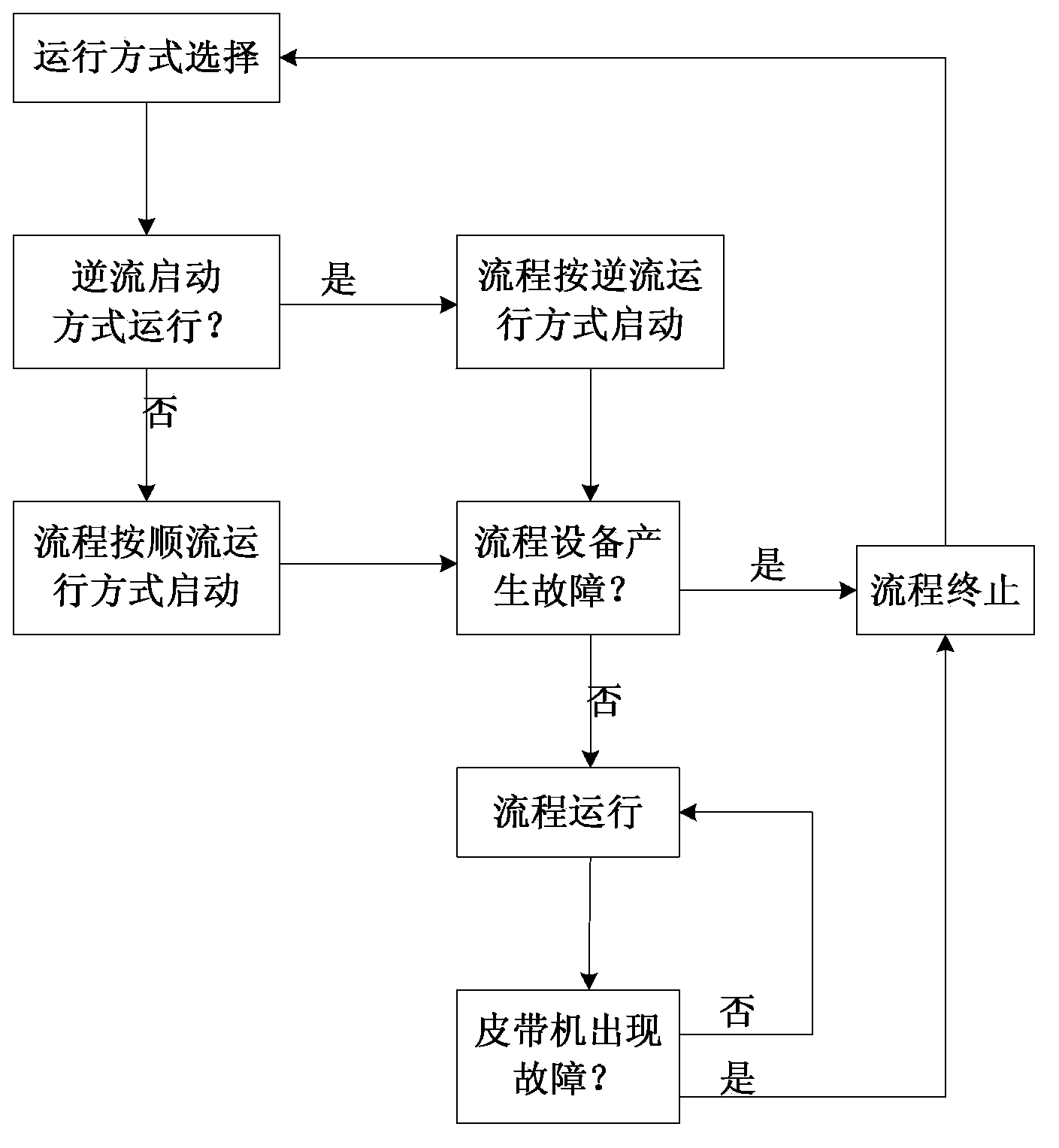

[0018] Such as figure 2 Shown is the flow chart of the present invention.

[0019] In the present invention, multi-stage belt conveyors are controlled, and the present embodiment takes four-stage belt conveyors B1, B2, B3, and B4 as an example to illustrate the control method. The main operation process is as follows:

[0020] (1) The start signal is used to control the operation of the main program. In the main program, choose to start the belt conveyor in the upstream or downstream mode.

[0021] (2) When reverse flow start is selected, belt conveyor B4 starts first, and after 3 seconds, belt conveyor B3 starts to start, and after B3 starts to run for 3 seconds, belt conveyor B2 starts to run, and after B2 starts to run for 3 seconds, B1 starts to run The system starts to start, and the system begins to load and run. If there is a process equipment failure at this time, the upstream equipment of the faulty equipment will not be able to start, and a message prompt and soun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com