Elevation LED panel mechanical arm

A robotic arm and panel technology, applied in the field of LED panel transportation tools, can solve the problems of fragility, inconvenient installation, and difficulty in manual arrival

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

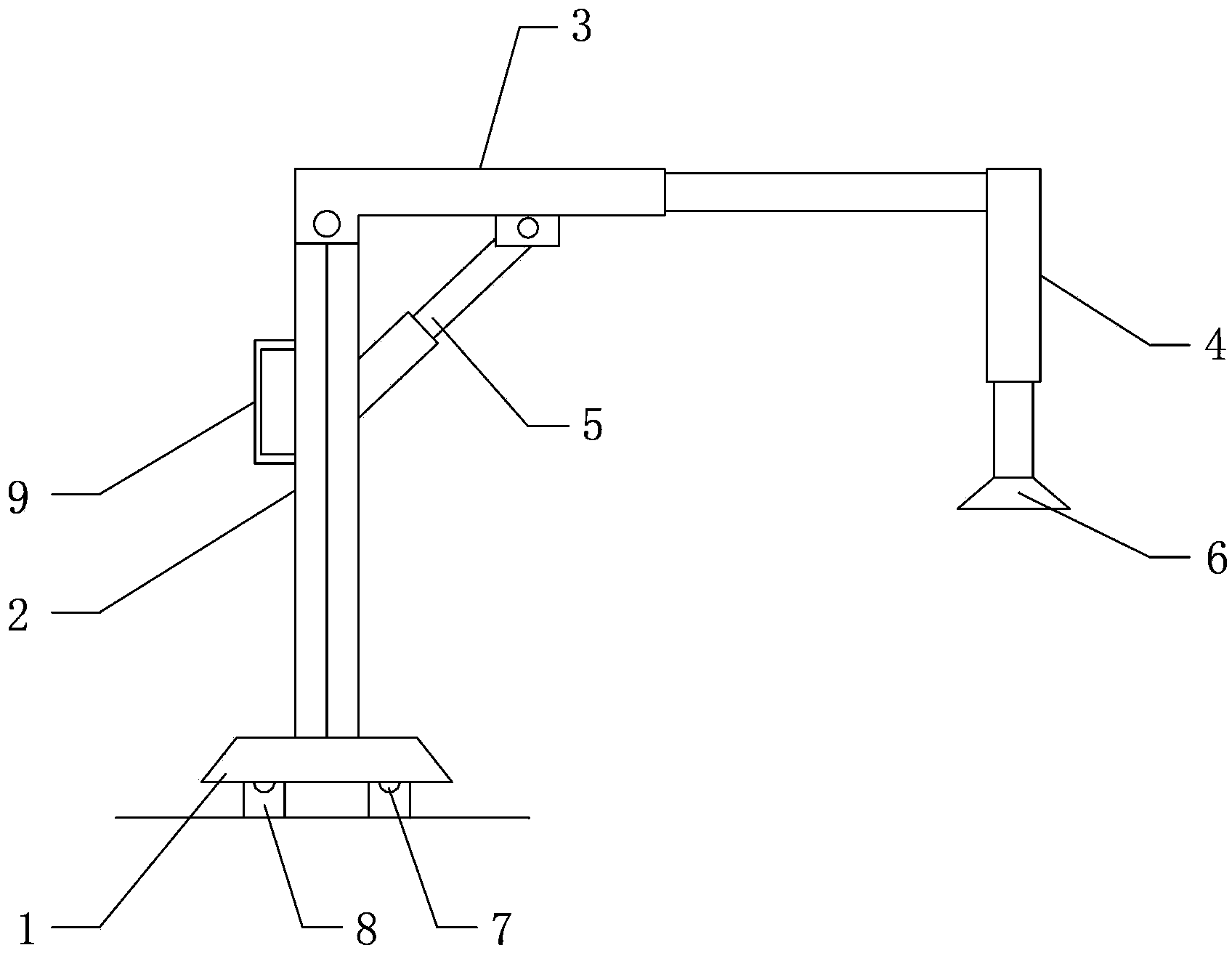

[0009] like figure 1 An elevation angle LED panel mechanical arm is shown, comprising: a base 1, a support arm 2, a movable arm 3 and a suction cup connecting arm 4; the support arm 2 is fixed on the base 1; the movable arm 3 is fixed on the top of the support arm 2 through a rotating shaft, And a hydraulic cylinder 5 is provided between the support arm 2 and the movable arm 3; the movable arm 3 front end is fixed with a suction cup connecting arm 4, and the direction of the suction cup connecting arm 4 is vertically downward; the suction cup connecting rod 4 lower ends are fixed with a suction cup 6; The arm 3 and the suction cup connecting arm 4 adopt a hydraulic telescopic cylinder; the lower end surface of the base 1 is provided with a pulley 7, and cooperates with the slideway 8 fixed on the ground; the support arm 2 is provided with a handle 9;

[0010] The present invention adopting the above-mentioned technical scheme realizes overall lifting by adopting the support ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com