Glass metal bonding sealing process based on force thermoelectric coupling condition

A glass-to-metal, thermoelectric coupling technology, applied in the field of glass-to-metal sealing technology, can solve problems such as unusable, inapplicable, and no successful cases, and achieve low air leakage, high production efficiency, high vacuum and heat collection performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Before sealing: Polish, level, clean and dry the end face of the glass nozzle of the solar vacuum heat collecting tube (conventional technology) to ensure the smoothness of the bonding surface. Polishing, leveling, cleaning and drying (conventional technology) on the metal sheet 4 (round kovar alloy sheet, which can be covered with the glass nozzle of the solar vacuum heat collection tube and whose shape matches) to ensure the integrity of the bonding surface bright and clean.

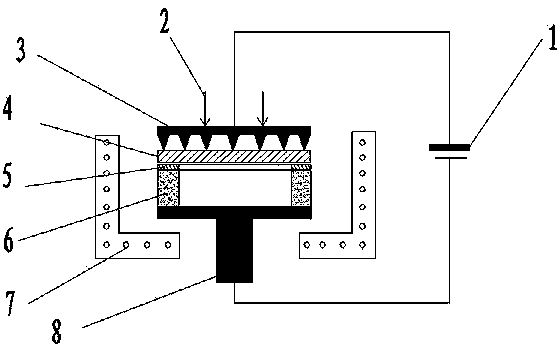

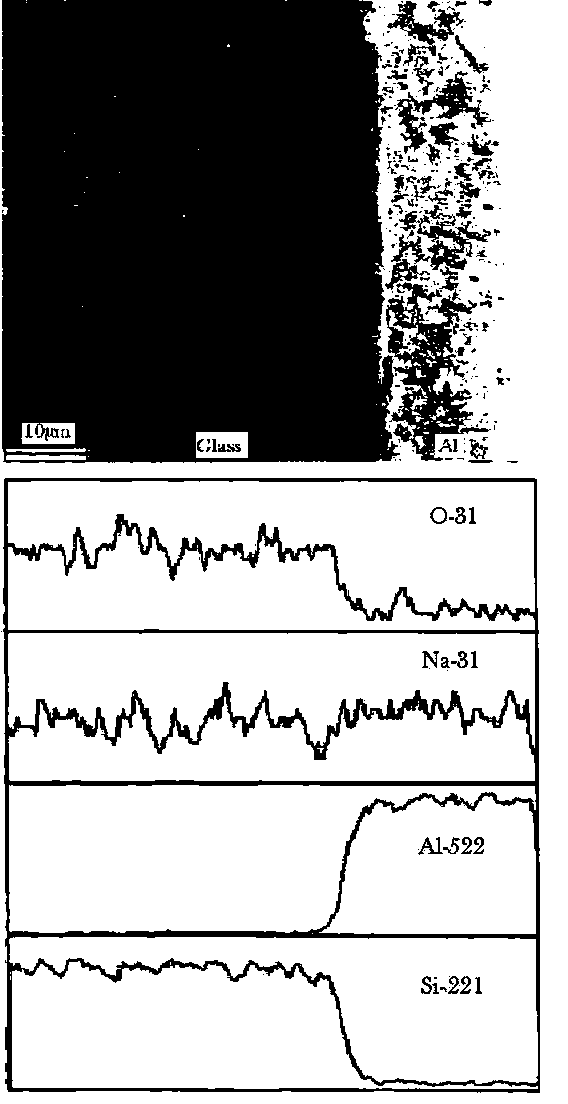

[0036] Such as figure 1 As shown, the end face of the glass nozzle 6 of the solar vacuum heat collecting tube is clamped and fixed with a clamp 8 (conventional clamp) upwards, and then the middle aluminum solder is stacked. The shape of the end face of the glass nozzle matches, and the thickness is 1-5 μm (this embodiment adopts 2 μm), and finally the Kovar alloy sheet is covered, and it is necessary to ensure that the entire glass surface (that is, the end face of the glass nozzle of the solar...

Embodiment 2

[0039] Before sealing: Polish, level, clean and dry the end face of the glass nozzle of the solar vacuum heat collecting tube (conventional technology) to ensure the smoothness of the bonding surface. Polishing, leveling, cleaning and drying (conventional technology) for the metal sheet (round aluminum sheet, no special requirements for thickness, can be covered with the glass nozzle of the solar vacuum heat collection tube, and the shape matches) to ensure the bonding The smoothness of the face.

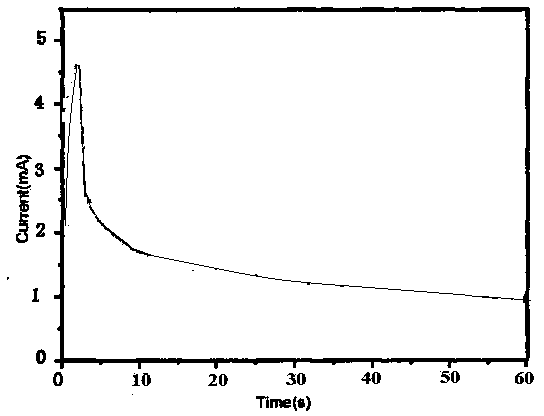

[0040] The end face of the glass nozzle of the solar vacuum heat collecting tube is clamped and fixed with the fixture 8 (conventional fixture), and then covered with an aluminum sheet, placed under vacuum conditions, and the entire glass surface (that is, the glass of the solar vacuum heat collecting tube) The end face of the nozzle) and the aluminum sheet are bonded horizontally, the temperature field (realized by electric heating) starts to heat up from room temperature, and the ...

Embodiment 3

[0043] Before sealing: Polish, level, clean and dry the end face of the glass nozzle of the solar vacuum heat collecting tube (conventional technology) to ensure the smoothness of the bonding surface. Polishing, leveling, cleaning and drying (conventional technology) on the metal sheet (round kovar alloy sheet, which can be covered with the glass nozzle of the solar vacuum heat collection tube, and the shape matches) to ensure the smoothness of the bonding surface .

[0044] The end face of the glass nozzle of the solar vacuum heat collecting tube is clamped and fixed with the clamp 8 (conventional clamp), and then covered with a Kovar alloy sheet, and the entire glass surface (that is, the end face of the glass nozzle of the solar vacuum heat collecting tube) ) and the Kovar sheet are bonded horizontally, the temperature field (realized by electric heating) starts to heat up from room temperature, and the heating rate is 0.1-5°C / min. In this embodiment, the heating rate is 3°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com