Environmentally friendly and efficient grouting agent

A kind of grouting agent and high-efficiency technology, applied in the field of grouting agent, can solve the problems of poor adaptability between cement and water reducing agent, large bleeding of freshly mixed slurry, complicated preparation process, etc., achieve remarkable physical water reducing effect, reduce cement The effect of standard consistency and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

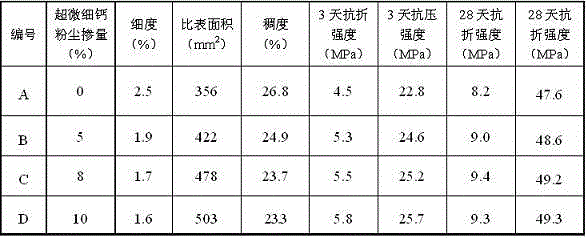

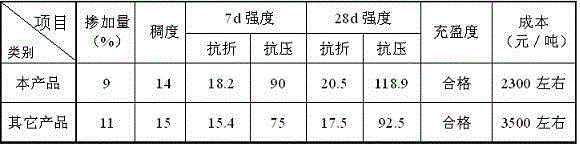

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Environmentally friendly and high-efficiency grouting agent, which is prepared by mixing the following raw materials evenly: 1.6g sodium dodecyl sulfonate, 0.2g methyl cellulose, 22g polycarboxylate water reducer, 134g UEA expansion agent, Ultrafine calcium dust 80g, gas ash 64g.

Embodiment 2

[0024] Example 2 Environmentally friendly and high-efficiency grouting agent, which is prepared by mixing the following raw materials uniformly: 1.8g sodium dodecyl sulfonate, 0.4g methyl cellulose, 20g polycarboxylate water reducer, 136g UEA expansion agent, Ultrafine calcium dust 85g, gas ash 57g.

Embodiment 3

[0025] Example 3 Environmentally friendly and high-efficiency grouting agent, which is prepared by mixing the following raw materials evenly: 2.0g sodium dodecyl sulfonate, 0.6g methyl cellulose, 18g polycarboxylate water reducer, 138g UEA expansion agent, Ultrafine calcium dust 90g, gas ash 50g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com