Orientation silicon steel and manufacturing method thereof

一种取向硅钢、制造方法的技术,应用在制造工具、电感/变压器/磁铁制造、磁性材料等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

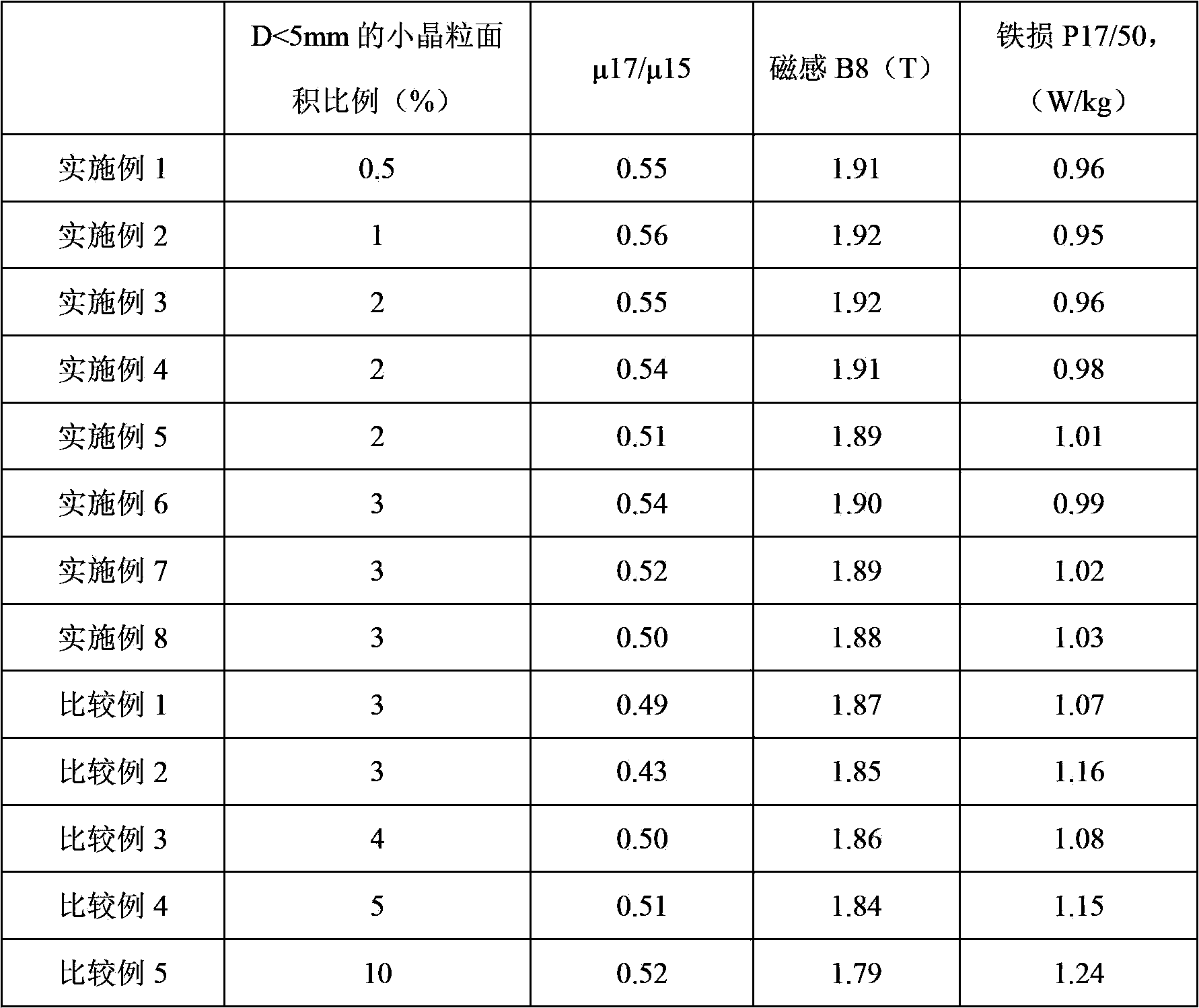

Embodiment 1-8 and comparative example 1-5

[0031] The components and weight percentages of oriented silicon steel slabs are C: 0.050%, Si: 3.0%, Als: 0.030%, N: 0.007%, S: 0.008%, Mn: 0.14%, and the rest are Fe and unavoidable impurities. Heat the slab in a heating furnace at 1000-1250°C and then hot-roll it to a thickness of 2.5 mm, then cold-roll the hot-rolled plate, and roll the hot-rolled plate to 0.30 with different cold rolling reductions. After the thickness of mm finished product, decarburization annealing is carried out, the annealing separator with magnesium oxide as the main component is coated, and high-temperature annealing is carried out after coiling; nitriding treatment is carried out after the final cold rolling and before high-temperature annealing and secondary recrystallization; Coating insulating coating and stretching and leveling annealing to obtain the finished product of oriented silicon steel. The relationship between the small grain area ratio of D<5mm in the finished grain-oriented silicon ...

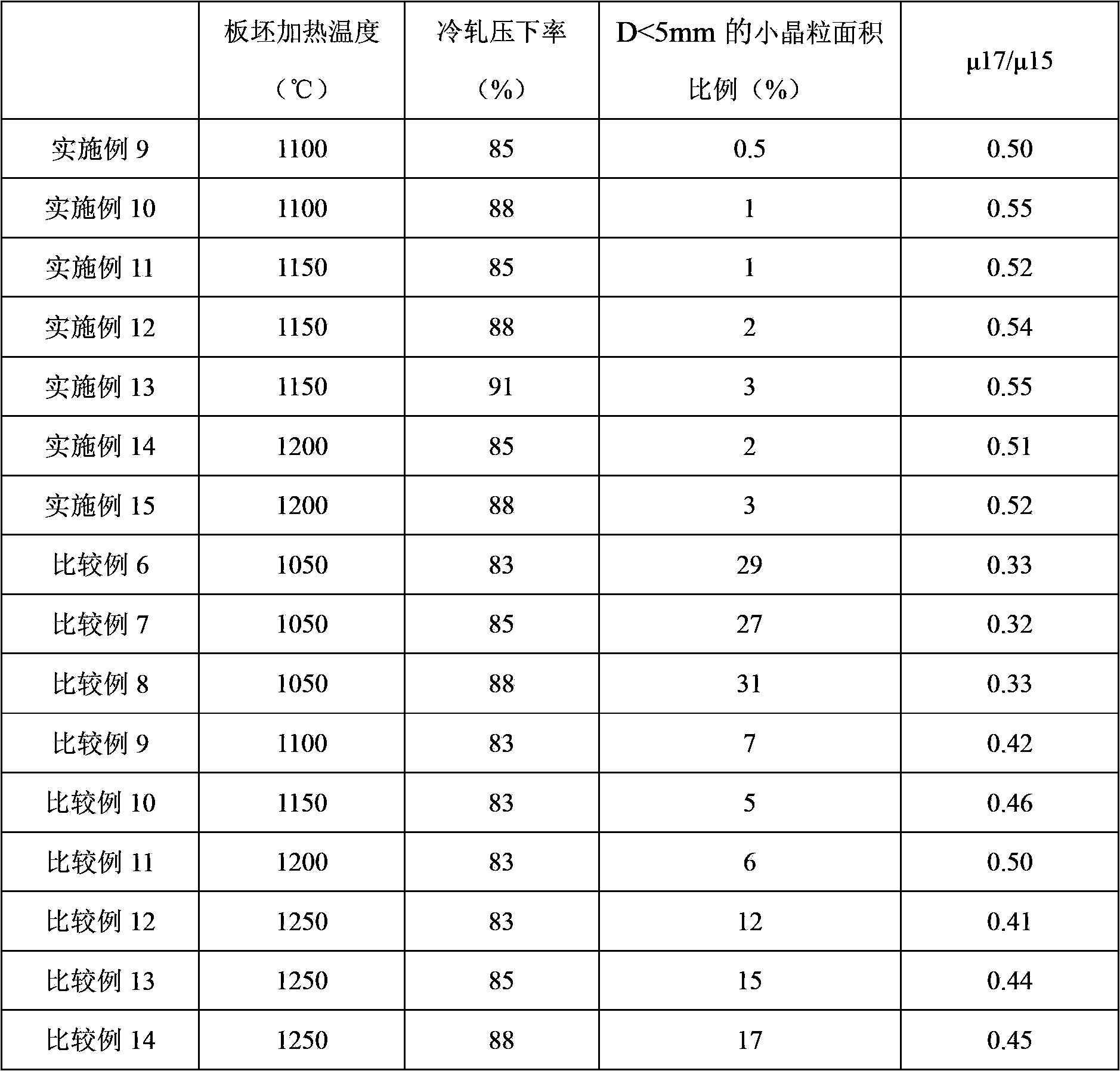

Embodiment 9-15 and comparative example 6-14

[0036] The components and weight percentages of oriented silicon steel slabs are C: 0.075%, Si: 3.3%, Als: 0.031%, N: 0.009%, S: 0.012%, Mn: 0.08%, and the rest are Fe and unavoidable impurities. The slab is heated in a heating furnace at five different heating temperatures of 1050-1250°C and then hot-rolled to a thickness of 2.3mm. After rolling to 0.20~0.40mm thickness of different specifications, decarburization annealing is carried out, annealing separator with magnesium oxide as the main component is coated, and high temperature annealing is carried out after coiling; after final cold rolling, high temperature annealing before secondary recrystallization Carry out nitriding treatment; after uncoiling, it is coated with an insulating coating and stretched, leveled and annealed to obtain a finished product of oriented silicon steel. The relationship between the slab heating temperature and cold rolling reduction rate and the small grain area ratio of D<5mm in the finished g...

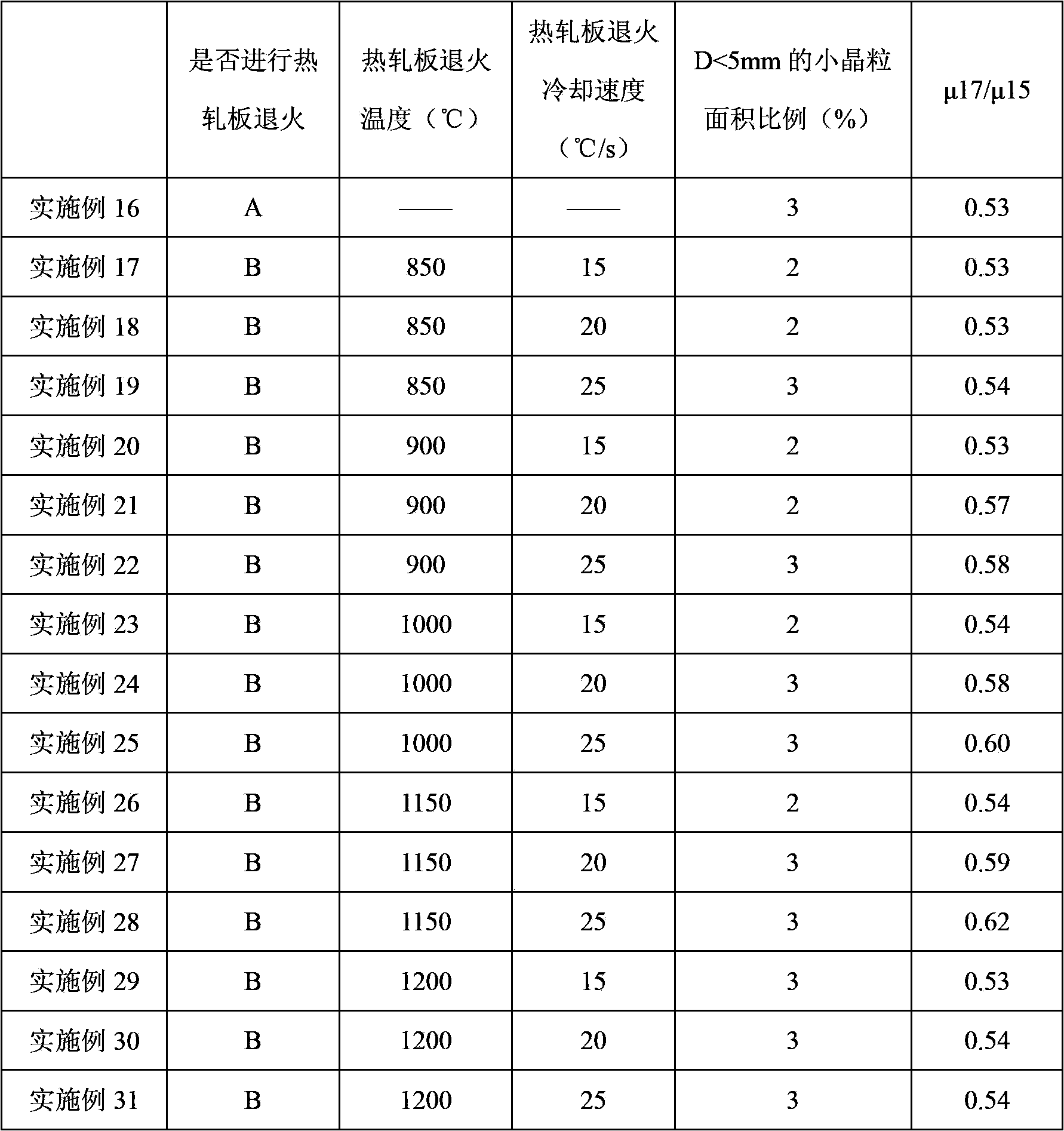

Embodiment 16-31

[0041] The components and weight percentages of oriented silicon steel slabs are C: 0.065%, Si: 3.2%, Als: 0.025%, N: 0.010%, S: 0.015%, Mn: 0.18%, and the rest are Fe and unavoidable impurities. The slab is heated in a heating furnace at 1150°C and then hot-rolled to a thickness of 3.0mm, and the hot-rolled sheet is subjected to (A) direct cold rolling, or (B) at a temperature of 850-1200°C and 15- The hot-rolled sheet is annealed at a cooling rate of 25°C / s, and then cold-rolled at a cold-rolling reduction rate of 85%. After rolling to a finished product thickness of 0.30mm, decarburization annealing is performed, and magnesium oxide is coated as the main component. Annealing separator, high-temperature annealing after coiling; nitriding treatment after final cold rolling and before high-temperature annealing and secondary recrystallization; after uncoiling, apply insulating coating and stretching and leveling annealing to obtain finished oriented silicon steel. The relation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| magnetic permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com