Vacuum filming workpiece rotation table

A vacuum coating and workpiece technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems of large thickness of the stage, inconvenient use process, easy high temperature deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A preferred embodiment is given below, and the present invention is more clearly and completely described in conjunction with the accompanying drawings.

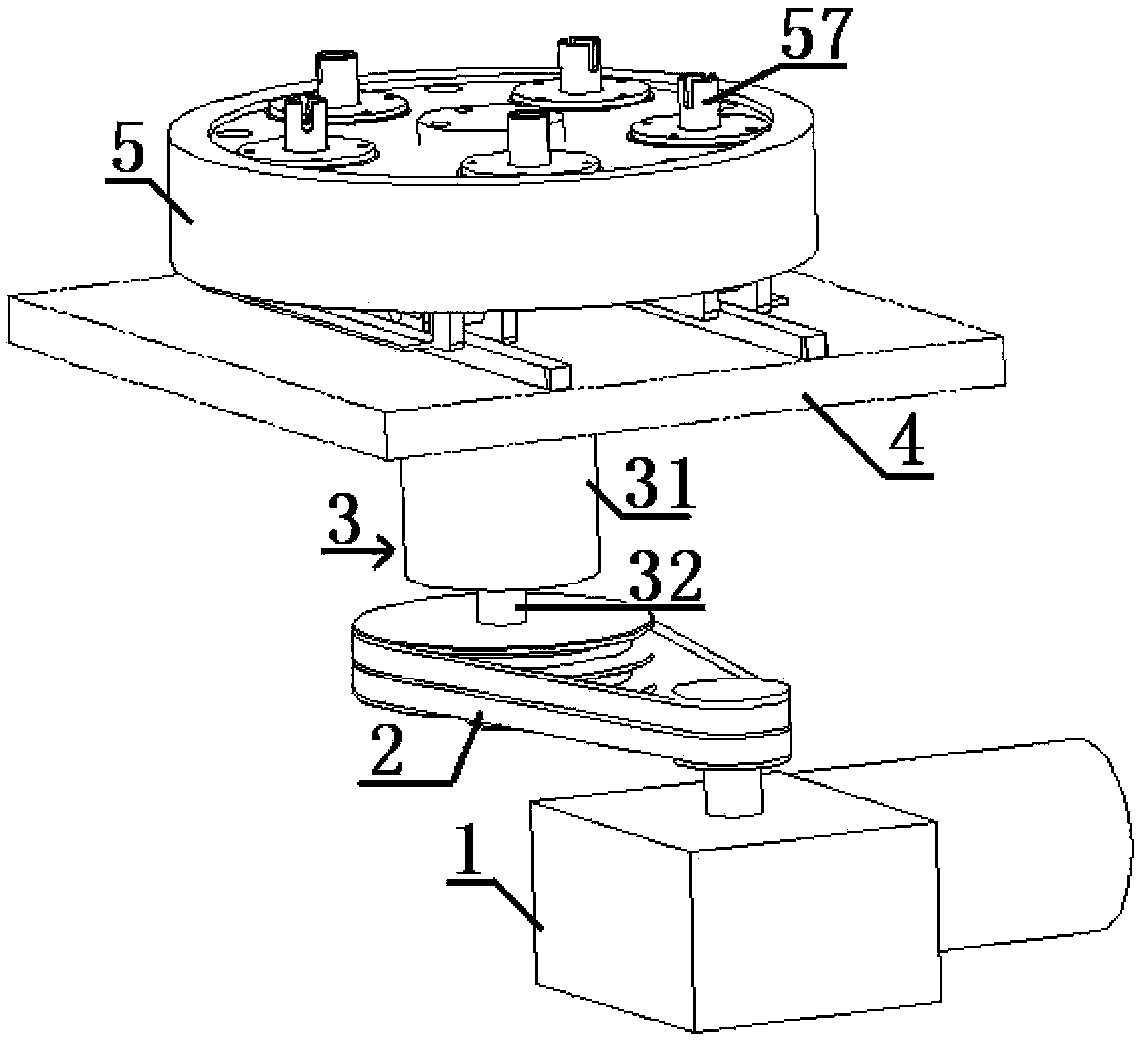

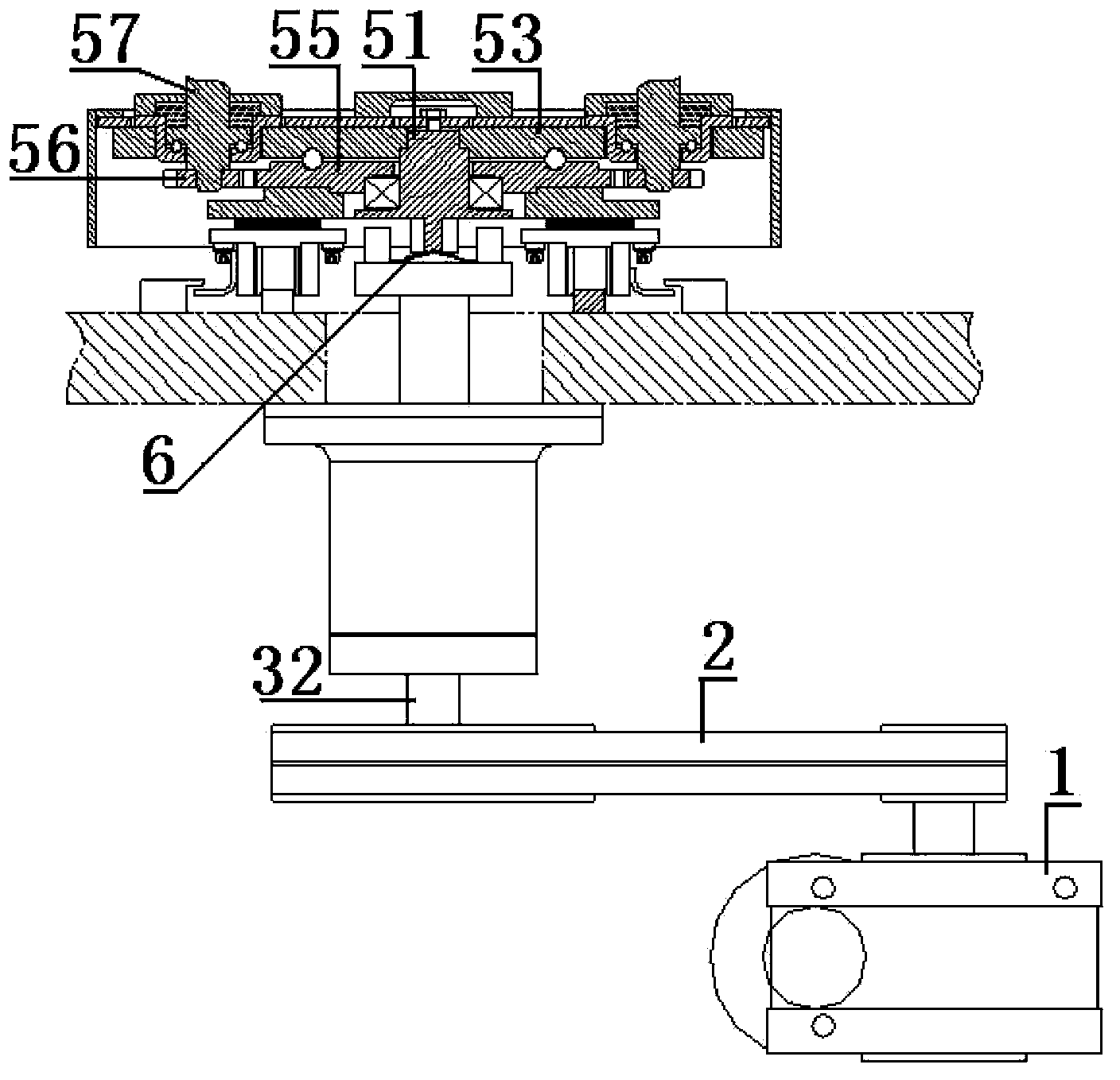

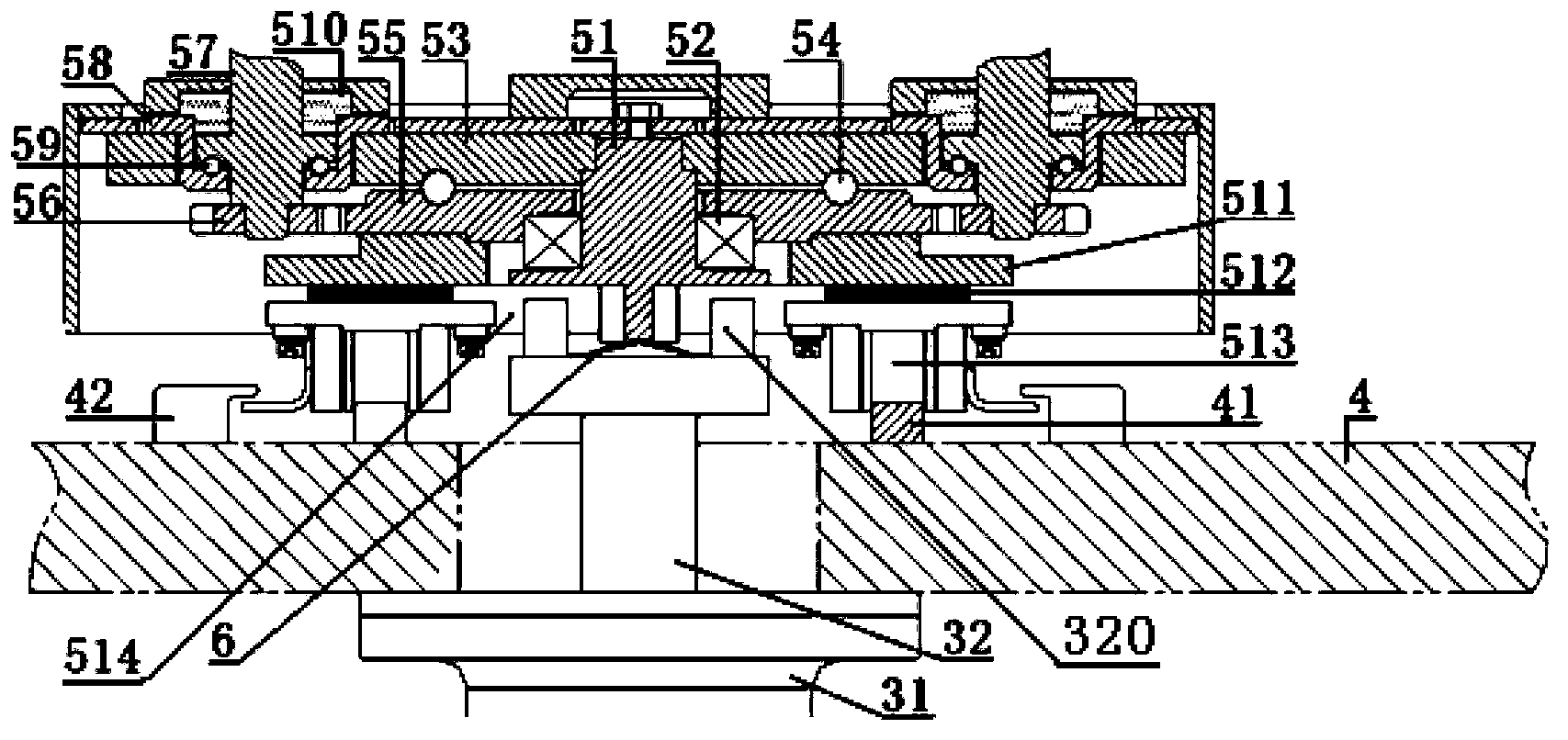

[0035] Such as figure 1 As shown, the vacuum coating workpiece turntable of this embodiment includes a motor 1 , a transmission base 3 , a vacuum chamber 4 and a stage 5 . The transmission base 3 includes a base cover 31 and a driving shaft 32 , and the driving shaft 32 is pivotally connected to the base cover 31 . Five rotation axes 57 are arranged on the stage 5 .

[0036] When working, the motor 1 drives the driving shaft 32 in the transmission base 3 to rotate through the transmission belt 2, and the driving shaft 32 drives the rotation shaft 57 in the stage 5 to rotate. Pre-processed workpieces are suspended on these rotation shafts 57, and the vacuum chamber 4 is airtight and surrounds the object stage 5. There is a positive ion emission source in the vacuum chamber 4, and the positive ion emission source cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com