Variable-cross-section channel of multi-stage cusped magnetic field plasma pusher

A technology of plasma and tangent magnetic field, which is applied in the field of plasma thrusters, can solve the problems of gas working medium leakage and other problems, and achieve the effects of eliminating secondary plume, increasing thrust, high specific impulse and benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

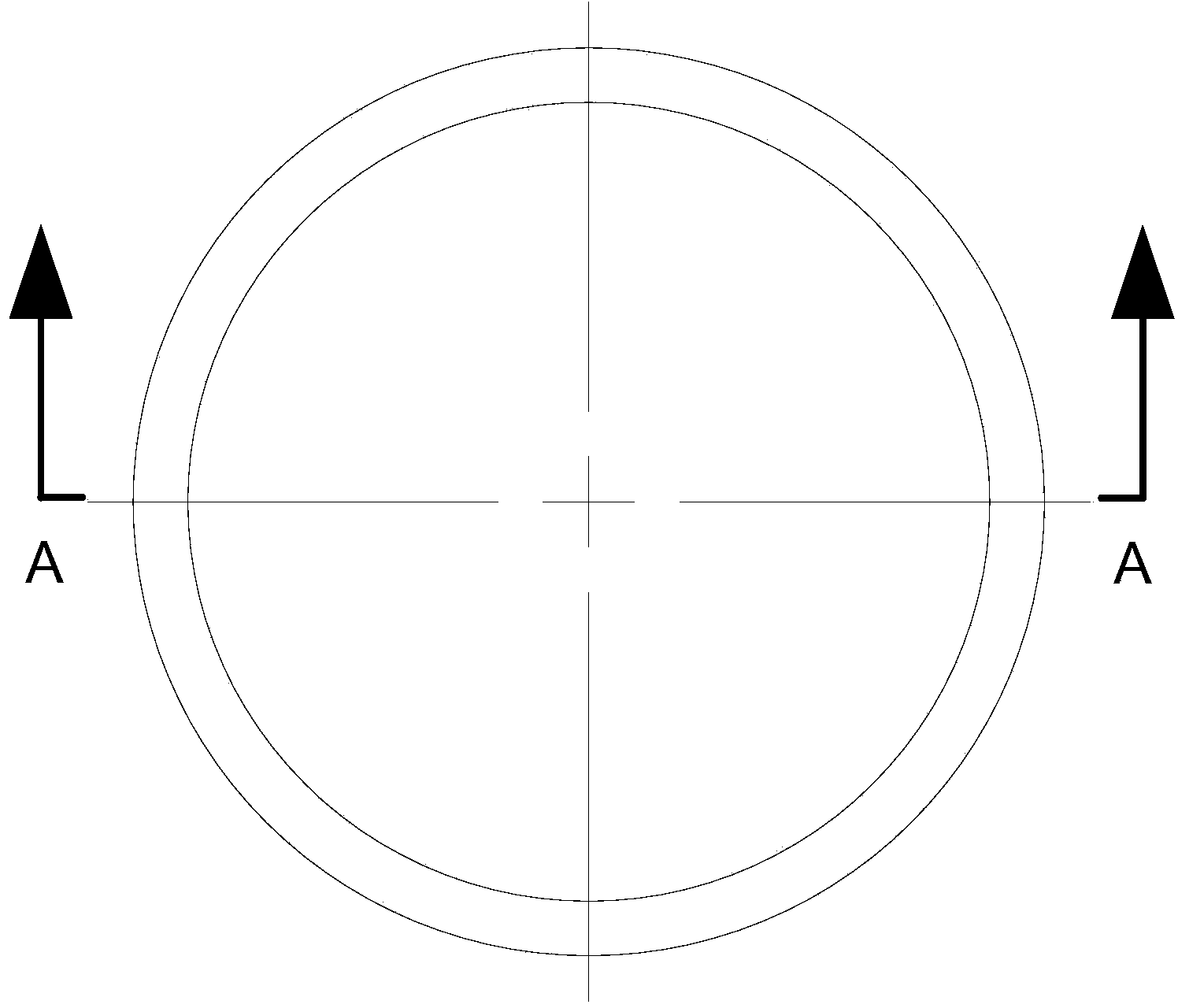

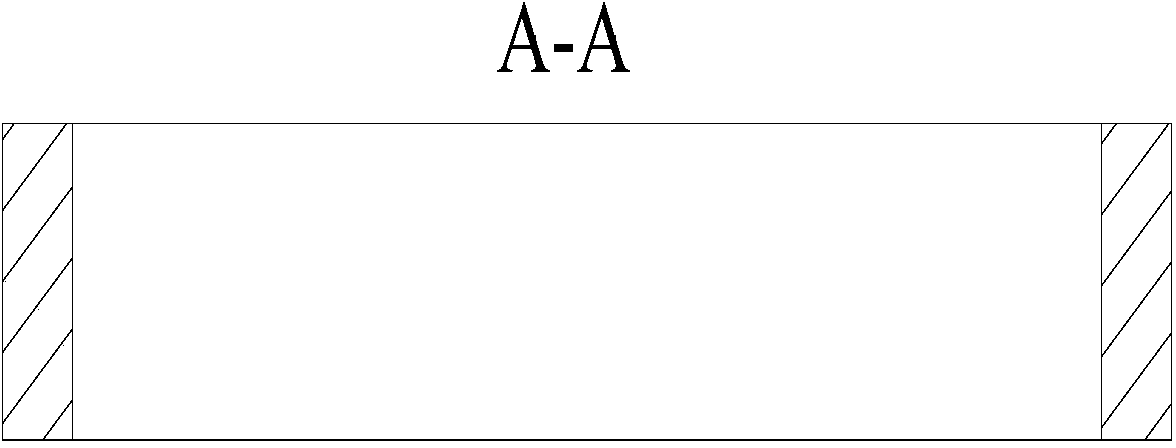

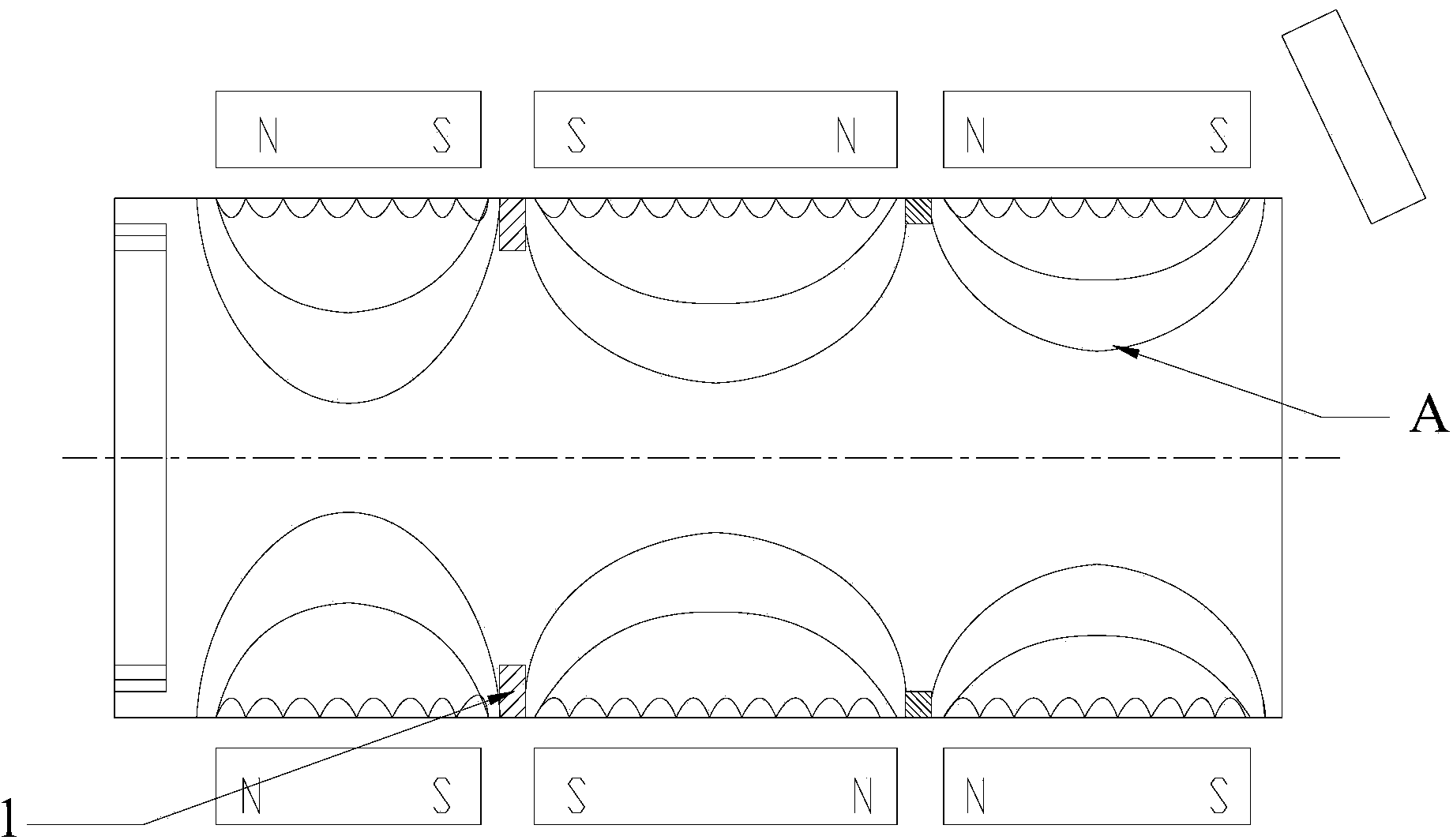

[0016] Specific implementation mode one: refer to figure 1 , figure 2 and image 3 Specifically explain this embodiment, the variable cross-section channel of the multi-stage tangent magnetic field plasma pusher described in this embodiment, the inner wall of the ceramic channel of the plasma pusher is embedded with n circular rings along the axial direction of the ceramic channel Boss 1, the inner side walls of the n bosses 1 are all cylindrical surfaces, the difference between the inner diameter and outer diameter of the n bosses 1 is between 2mm and 10mm, and the inner diameters of the n bosses 1 are along the ceramic channel The anode to cathode gradually increases, where n is a positive integer.

[0017] In this embodiment, if the difference between the inner diameter and the outer diameter of the boss is too large, it will affect the axial movement of ions, and if it is too small, the improvement of the wall gas leakage phenomenon will not be obvious, so it is optimal...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment is a further description of the variable cross-section channel of the multi-stage tangential magnetic field plasma pusher described in Embodiment 1. In this embodiment, each boss 1 corresponds to the adjacent A magnetic tip between two poles.

[0019] The boss located at the magnetic tip of the ceramic channel can improve the ionization efficiency.

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment is to further explain the variable cross-section channel of the multi-stage tangential magnetic field plasma pusher described in Embodiment 1. In this embodiment, the inner wall of the ceramic channel of the plasma pusher Wavy.

[0021] When the straight ring boss is used, the inner wall of the ceramic channel is made into a wave surface, which can make the wall gas flow into a turbulent flow and more fully ionize the wall gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com