Automobile electronic gear shifting device and gear shifting method

A technology for automotive electronics and shifters, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problems of large vertical layout space, large layout space, large vertical layout space, etc., and achieve reduction Longitudinal arrangement of space, ensuring driving safety, and the effect of reducing interior space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

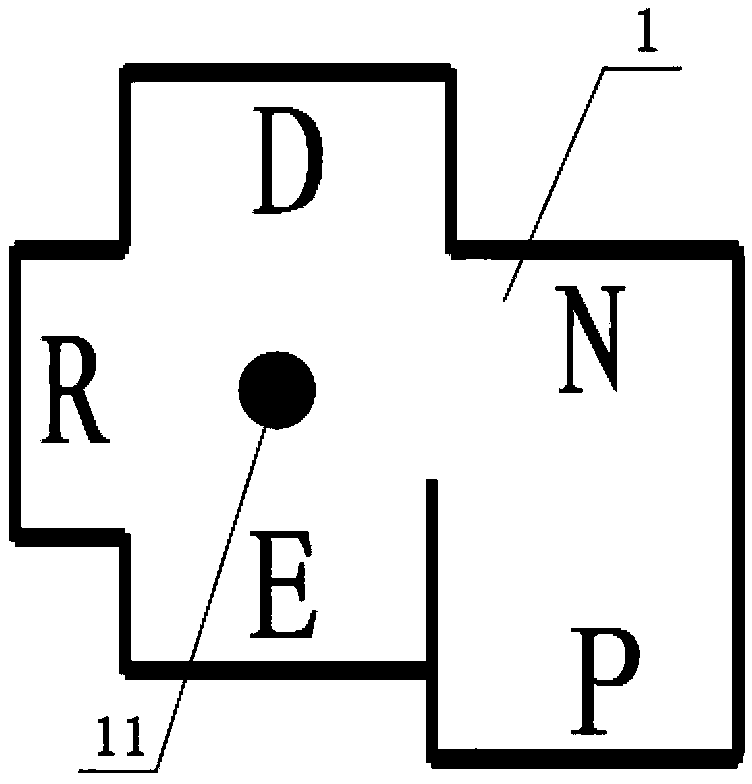

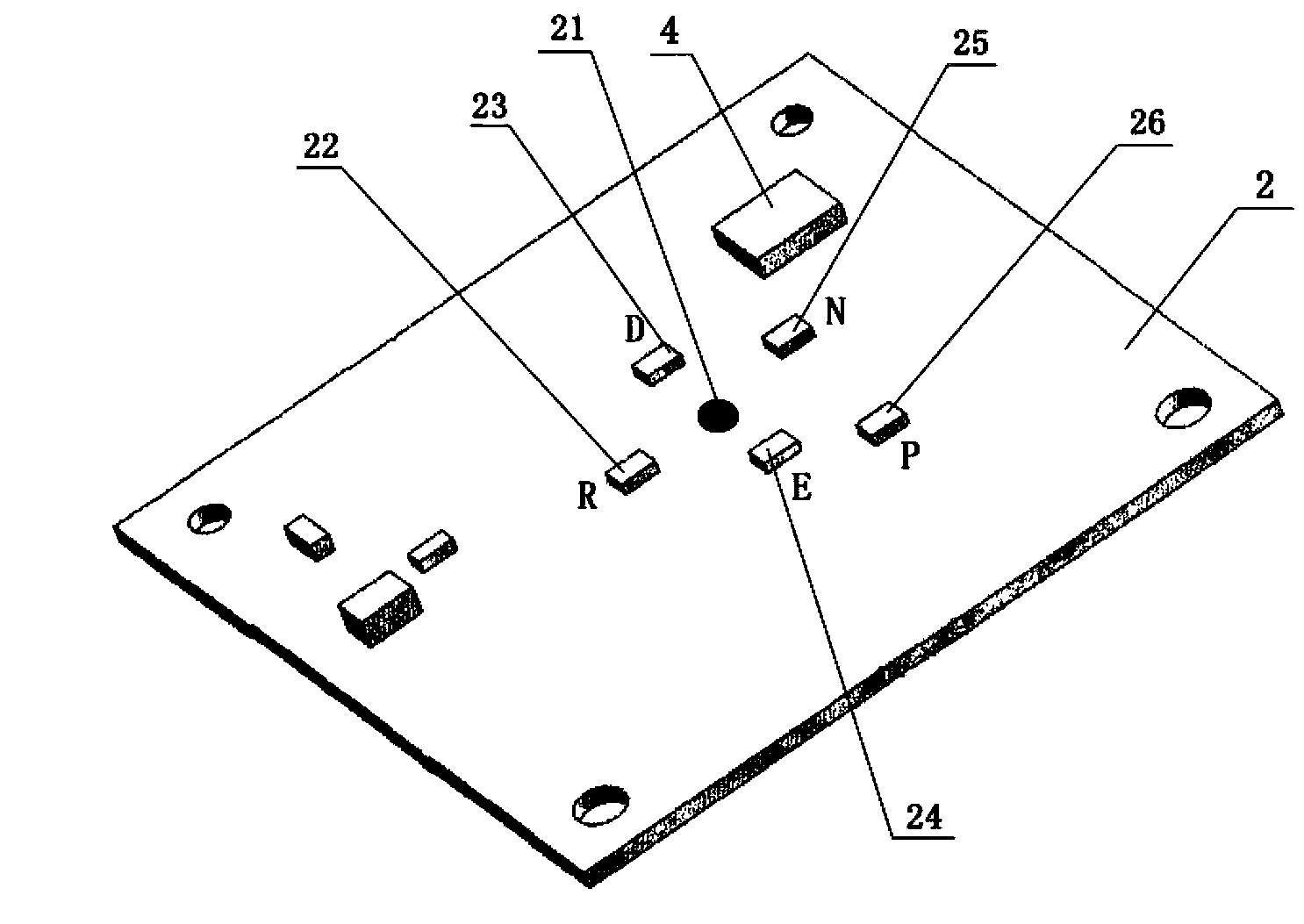

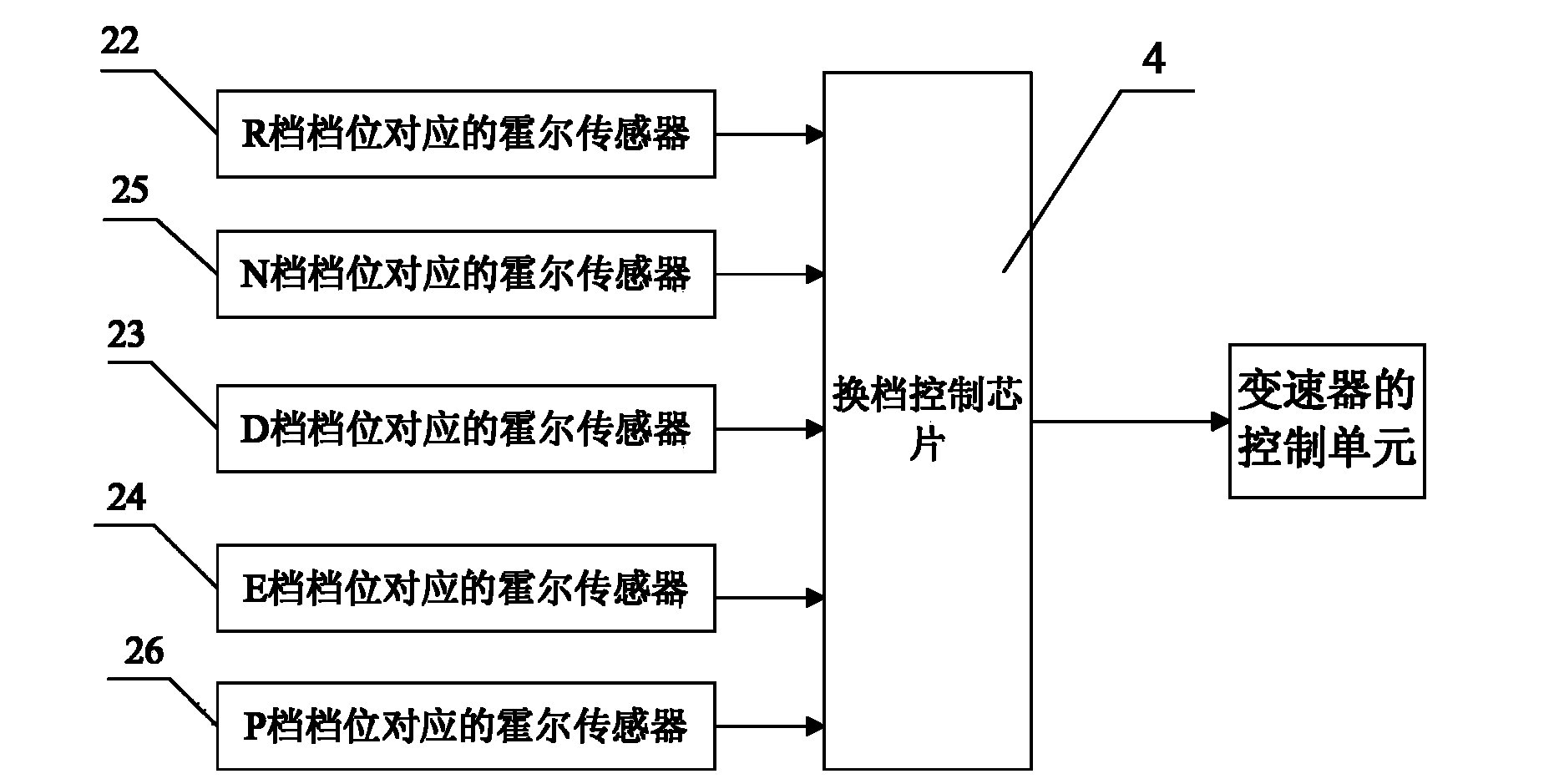

[0026] see figure 1 , figure 2, the automotive electronic gear shifter of the present invention includes a gear panel 1, a gear lever passing through 11 places on the gear panel and a circuit board 2 located below the gear lever, and the gear panel is marked with R, D, E, N, P gear positions, the lower end of the shift lever is fixedly connected with a permanent magnet, the initial position of the permanent magnet is the original position of the shift lever, and the original position corresponds to the starting point 21 on the circuit board, the circuit Board 2 is provided with Hall sensors corresponding to the R, D, E, N, and P gear positions marked on the gear panel and not in contact with the permanent magnet; wherein, the Hall sensor 22 corresponding to the R gear position Arranged on the left side of the starting point 21, the Hall sensor 23 corresponding to the D g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com