Cyclone for separating oil smoke in smoke ventilator

A technology of oil fume separation and cyclone, which is applied in the fields of oil fume removal, application, and household stoves, etc., can solve the problems of oil fume accumulation, oil fume noise, poor operation, etc., and achieve the effects of good health, air purification, and convenient processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

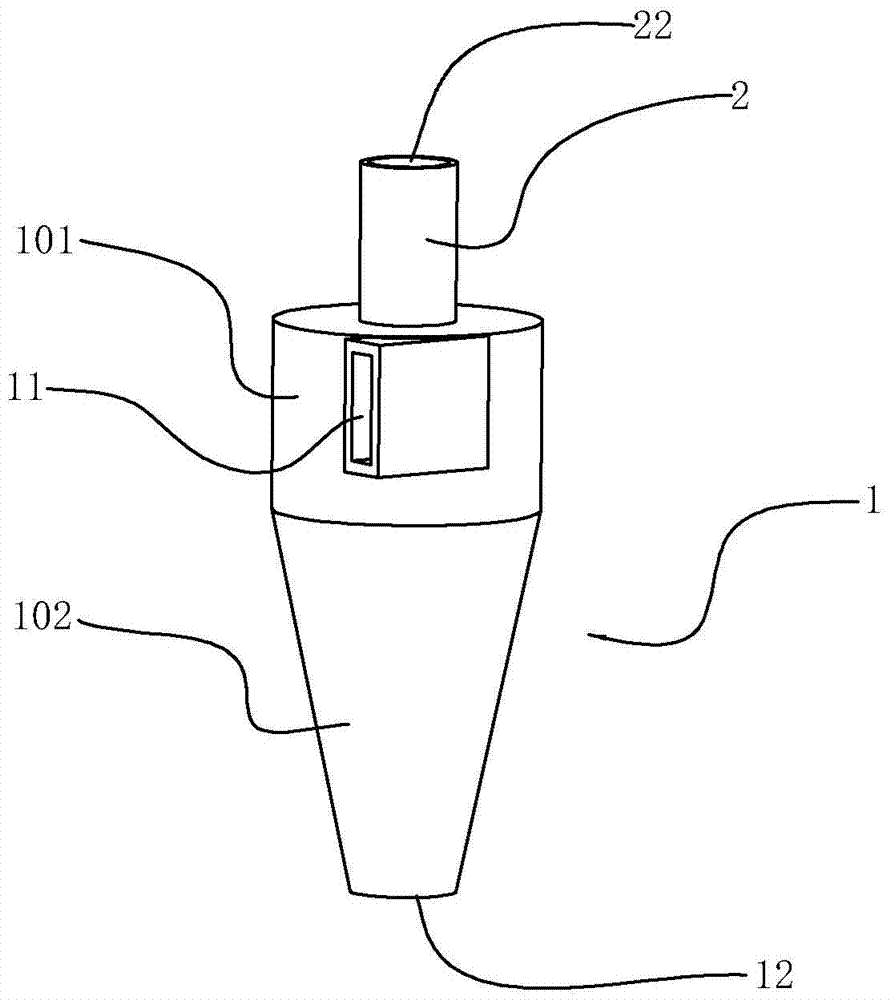

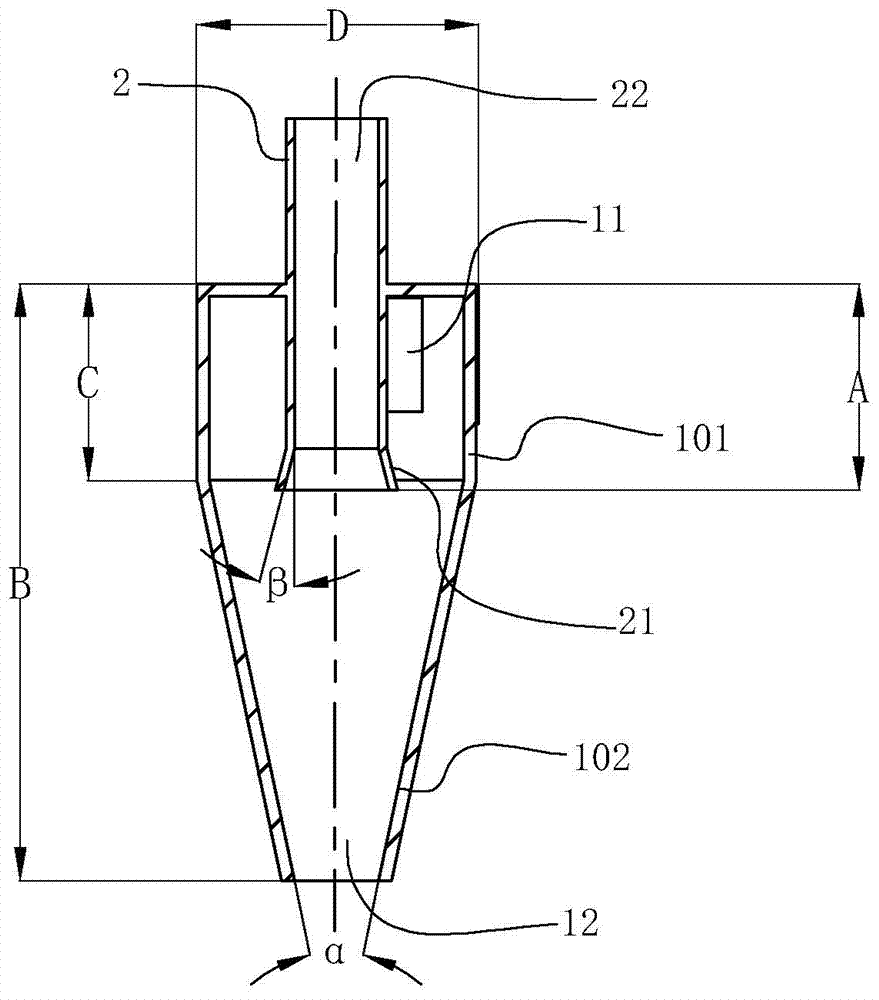

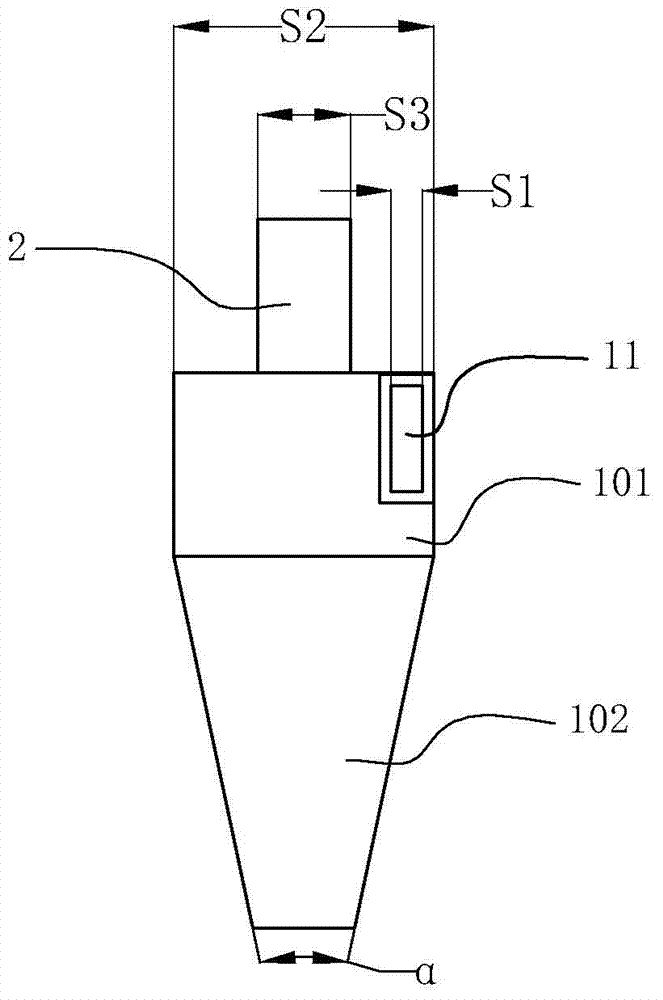

[0031] The first embodiment of the whirlwind used for range hood oil fume of the present invention, such as Figure 1-3 As shown, it includes a main body 1. The main body 1 of the cyclone is a hollow cylindrical structure whose radial dimension gradually decreases from top to bottom. Liquid port 12, the top of the body 1 is closed, and a central airway 2 is inserted into the top end, at least part of the central airway 2 is inserted into the body 1, and the central airway 2 can also be completely inserted into the body 1, And the top opening of the central air duct 2 is the air outlet 22 of the cyclone, and the air outlet 22 is not lower than the top of the main body 1 . The central air duct 2 is arranged coaxially with the body 1 . An air inlet 11 tangent to the side wall of the main body 1 is provided on the upper side wall of the main bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com