Embedded cavity multilayer printed board structure

A multi-layer printed board, printed board technology, applied in the direction of printed circuit components, etc., can solve the problem that the sound quality of hand-held electronic products fails to meet the expectations of consumers, achieve the extension of the propagation path, improve the overall performance, The effect of improving sound quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In conjunction with the accompanying drawings, the present invention is described in detail, but the scope of protection of the present invention is not limited to the following examples, that is, all simple equivalent changes and modifications made with the patent scope of the present invention and the content of the specification are still patents of the present invention. covered.

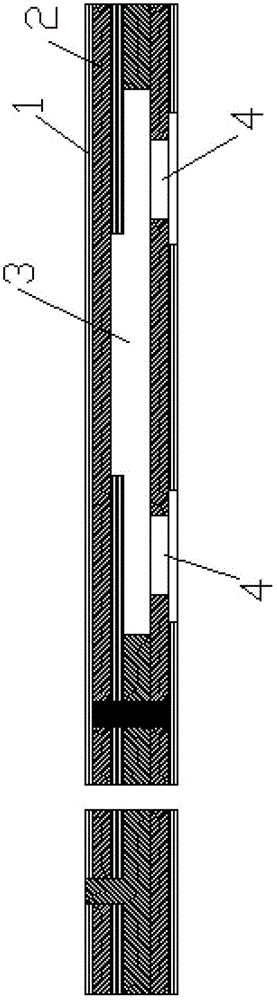

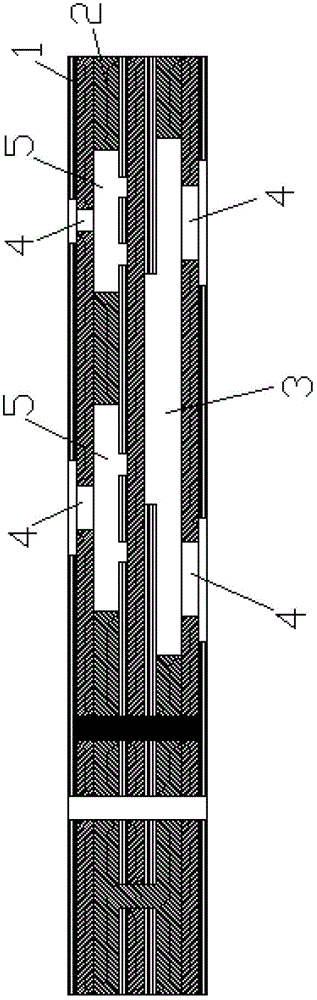

[0018] Such as figure 1 , 2 As shown, a multilayer printed board structure with a built-in cavity includes several layers of circuit layers 1 and an insulating layer 2 located between every two adjacent circuit layers, and the insulating layer located in the inner layer of the multilayer printed board At least one embedded cavity 3 for sound transmission is provided on at least one of the circuit layer, and the multilayer printed board is located on the same side of the embedded cavity for sound transmission and the insulating layer respectively penetrates the Two acoustic holes 4 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com