Aircraft fuselage and method for constructing a floor in such a fuselage

A technology for aircraft and fuselage, applied in the field of aircraft fuselage, can solve the problems of installation difficulty and time-consuming, and achieve the effect of good mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

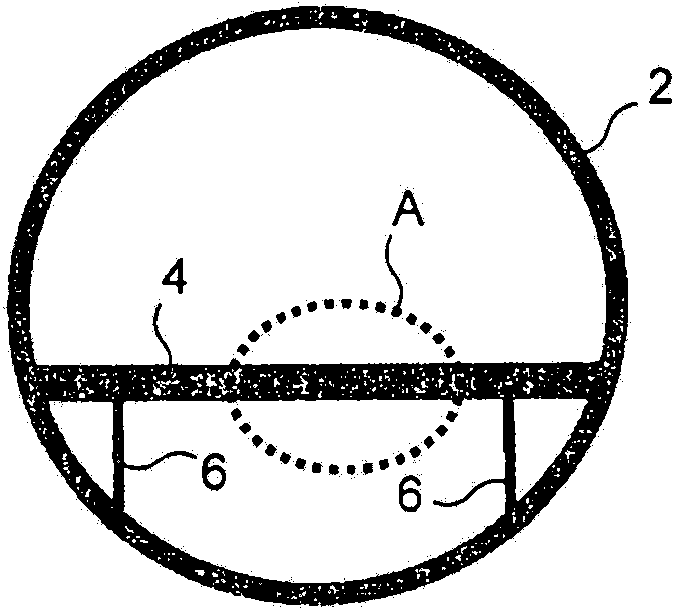

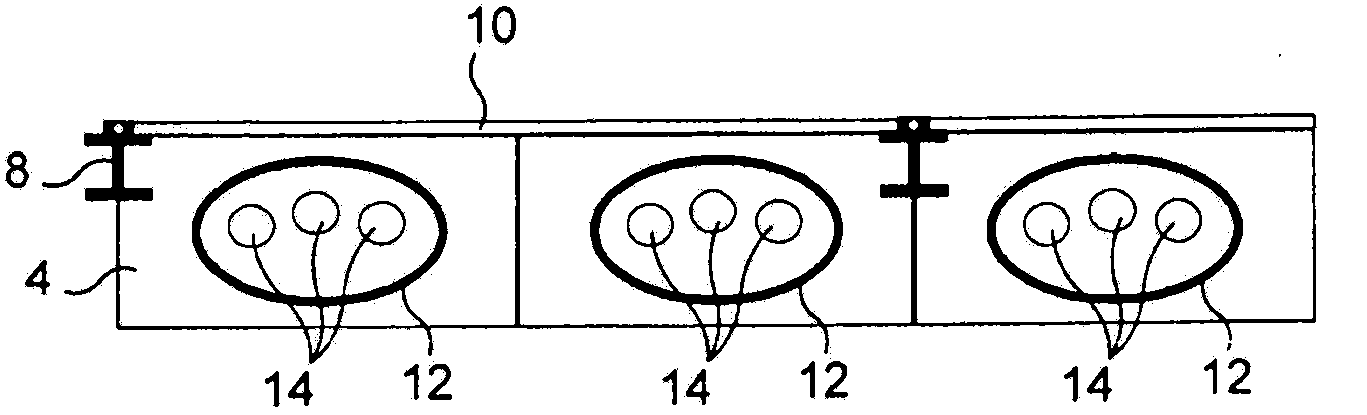

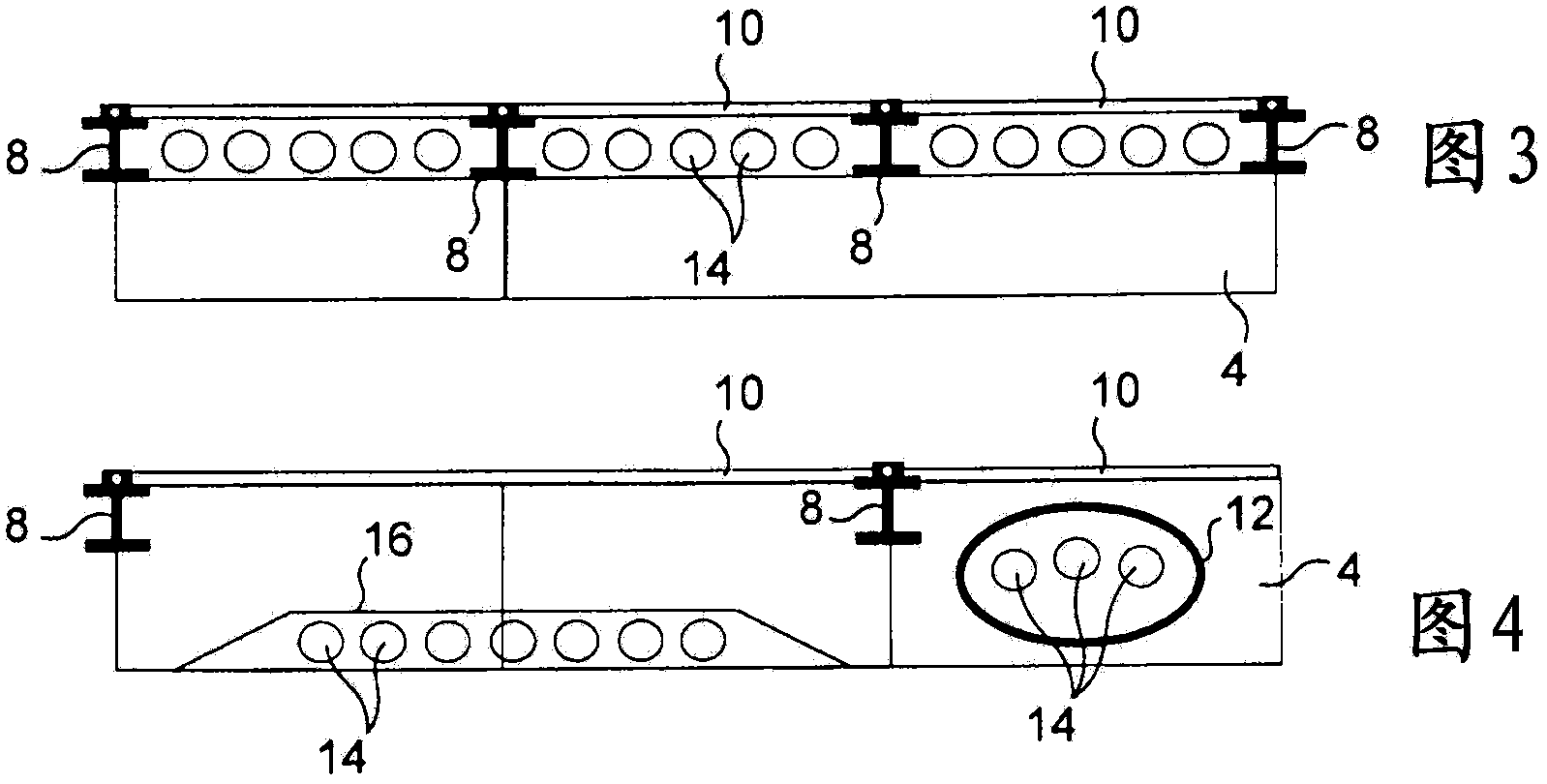

[0039] Figure 1 to Figure 4 already described at the beginning of this document. As mentioned in the beginning, Figure 5 is enlarged figure 1 Detail view of area A of . Should Figure 5 The structure of an aircraft floor according to the invention is shown. The floor comprises beams 104 according to the invention, longitudinal rails 108 and panels 110 of the floor.

[0040] The longitudinal rails 108 will not be described in detail here. In the floor according to the invention, the rails can have the shape of conventional longitudinal rails that are commonly used in aircraft floor structures and are used to accommodate, for example, cabin seats of aircraft. In the embodiment shown here, the longitudinal rail 108 is in the shape of a rail of an I-profile, which is also provided with a groove, which is used in particular to fasten a seat or other elements to the corresponding floor.

[0041] The panels 110 constituting the floor itself are not described again. This can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com