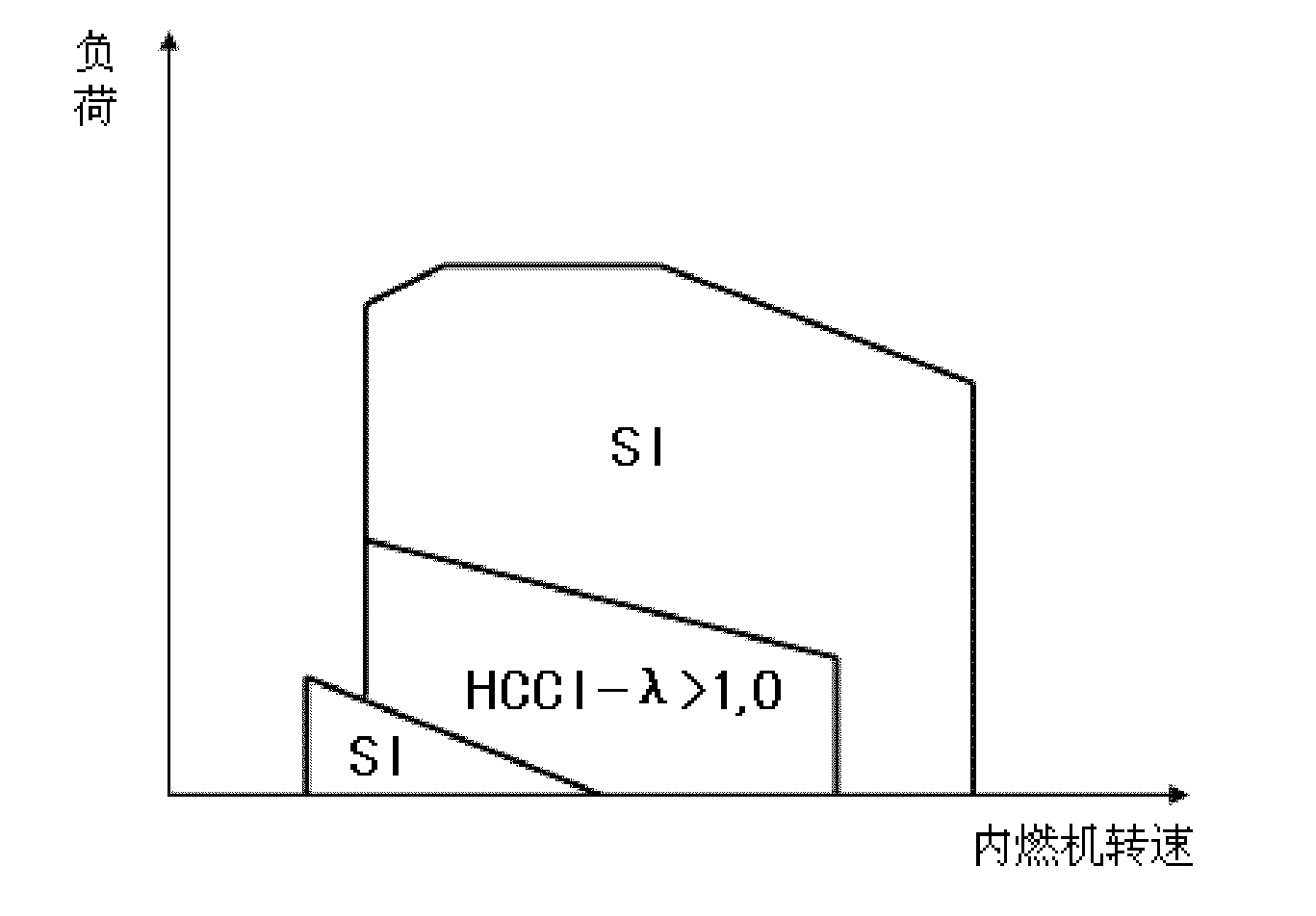

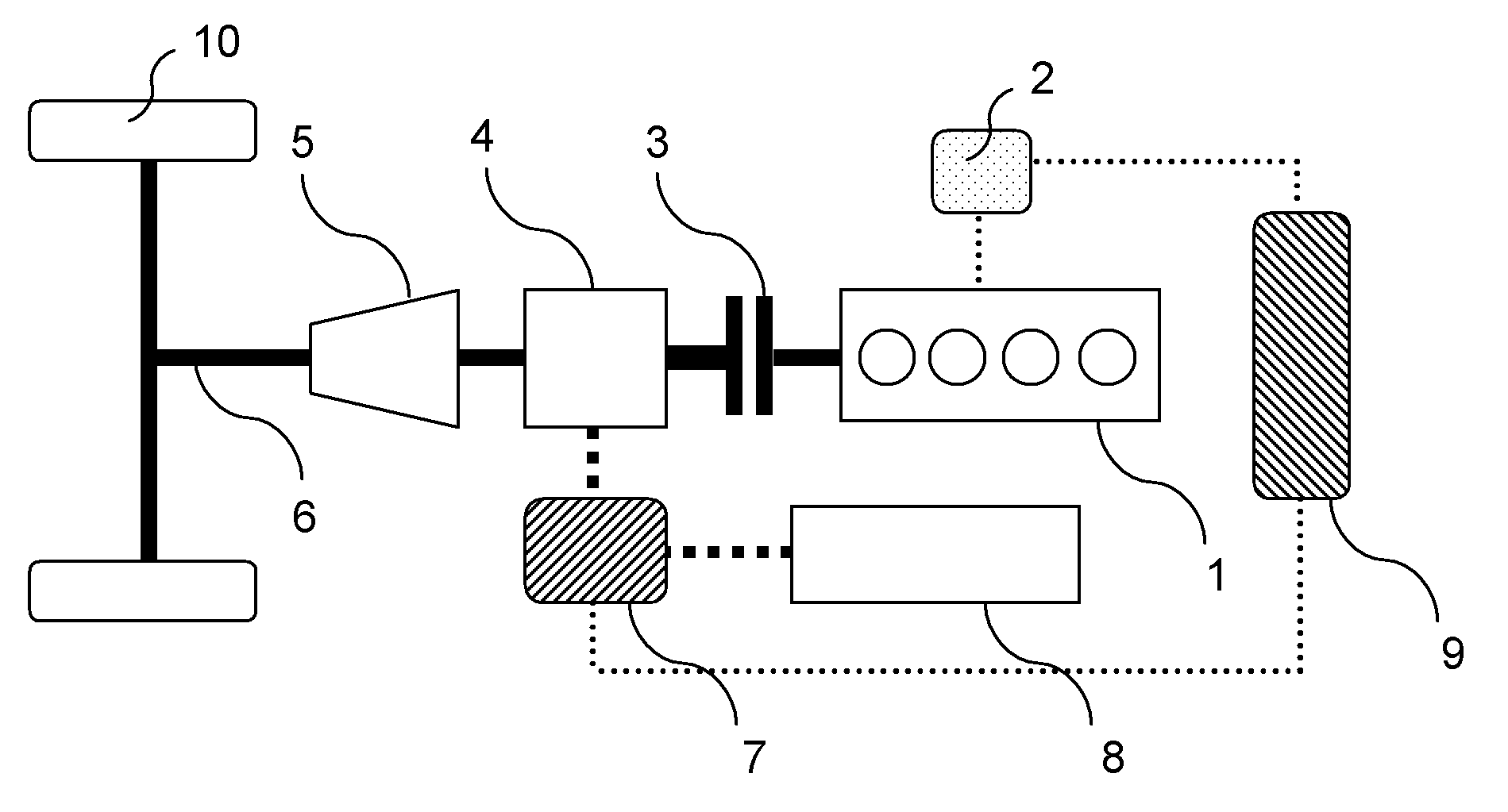

Hybrid power system, method and automobile based on dual-mode homogenizing compression ignition internal combustion engine

A technology of hybrid power system and homogeneous compression ignition, which is applied to the arrangement of multiple different prime movers of gas pressure power devices, power devices, and general power devices, and can solve the problem of insufficient ability to change working conditions and increase the production capacity of hybrid vehicles. Cost and maintenance costs, internal combustion engine output power surplus, etc., to meet the continuous high-power output requirements, expand high-load high-power output performance, and improve fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] First of all, it should be noted that the specific structure, control process and characteristics of the hybrid power system based on the dual-mode homogeneous compression ignition internal combustion engine of the present invention and the hybrid power control method realized by using the hybrid power system will be described below by way of example. and advantages, etc., but all descriptions are for illustration only, and should not be construed as forming any limitation on the present invention. In addition, any single technical feature described or implied in each embodiment mentioned herein, or any single technical feature shown or implied in each drawing, can still be described in these technical features (or their equivalents) ) to continue any combination or deletion, so as to obtain more other embodiments of the present invention that may not be directly mentioned herein.

[0037] In addition, unless otherwise specified, technical terms such as low speed, mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com