Method for controlling the acceleration of a package drive roll

A technology for driving rollers and bobbins, which is applied in the field of controlling the acceleration of bobbin driving rollers, can solve problems such as yarn breakage and kinks, and achieve the effects of optimizing productivity, avoiding overlapping winding, and shortening the start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

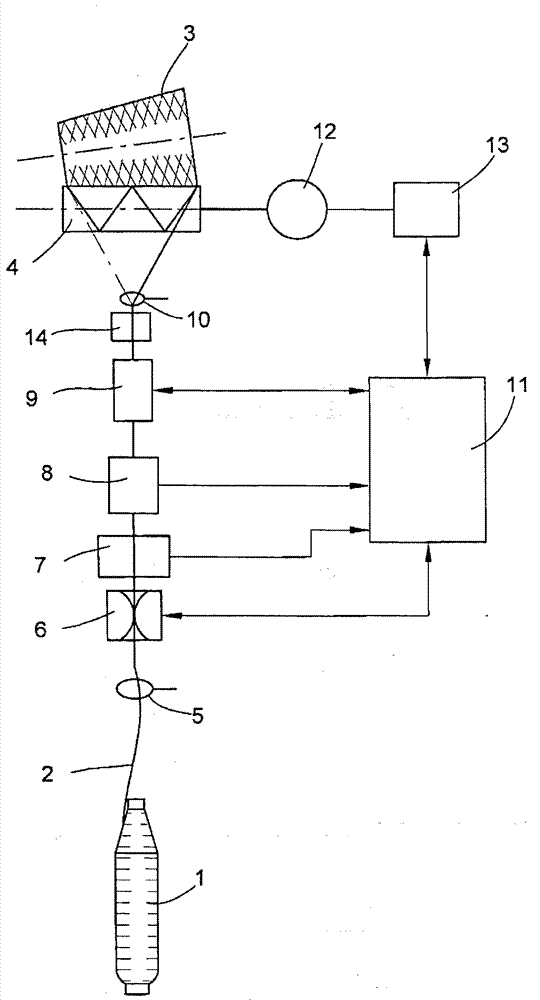

[0033] figure 1 Shown at various stations is the unwinding of yarn 2 from a feed bobbin 1, in particular a bobbin produced on a ring spinning machine, which is wound onto a cross-wound bobbin 3, for example a conical cross-wrap around the bobbin.

[0034] The cross-wound bobbin 3 held by a pivotable creel, not shown, rests against the bobbin drive roller 4, in particular against a so-called guide drum, with which the cross-wound bobbin 3 is rotated and the yarn 2 is drawn The cross-wound bobbins 3 are fed axially and traversingly. However, other types of yarn traversing devices are also conceivable within the scope of the invention, for example so-called finger yarn guides.

[0035] The yarn 2 (which is usually the yarn formed on the ring spinning machine) passes through the yarn guide 5, the controllable yarn tensioner 6, the yarn tension Sensor 9 and sensor in the form of yarn clearer 8 . The yarn tensioner 6 applies a predetermined clamping force to the running yarn 2 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com