Method for efficiently producing diethylene glycol dibenzoate

A technology of diethylene glycol dibenzoate and benzoic acid, which is applied in the chemical field, can solve the problems of production efficiency and quality, insufficient production and research of plasticizers, etc., and achieve low price, good compatibility, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

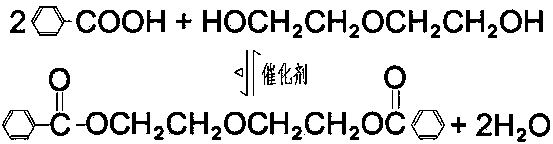

Method used

Image

Examples

Embodiment example

[0041] Put 3.87 tons of benzoic acid, 1.6 tons of diethylene glycol, and 16 kg of sodium bisulfate as a catalyst in the reactor. Heat the heat transfer oil through the heat transfer tube. When it is determined that all the benzoic acid is dissolved, start stirring. When the temperature is heated to 180°C, benzoic acid with water and sublimation will distill out. When there is little water flowing out, the temperature quickly rises to 200°C. At this time, it can be considered that the reaction is basically completed, and the heating is stopped. Use cooling heat transfer oil to pass into the heat transfer pipe to cool the reaction material. When the temperature in the reaction kettle drops to 100°C, it is drawn from the bottom of the reaction kettle through a pipeline and sent to the neutralization kettle. Neutralize the unreacted benzoic acid with 5% NaOH aqueous solution at 70°C and adjust to PH=8. After the reactants are stratified, the crude product in the lower layer is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com