pneumatic tire

A technology of pneumatic tires and treads, applied in special tires, tire parts, transportation and packaging, etc., can solve problems such as poor initial grip performance and product value decline, and achieve wear resistance and time degradation resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

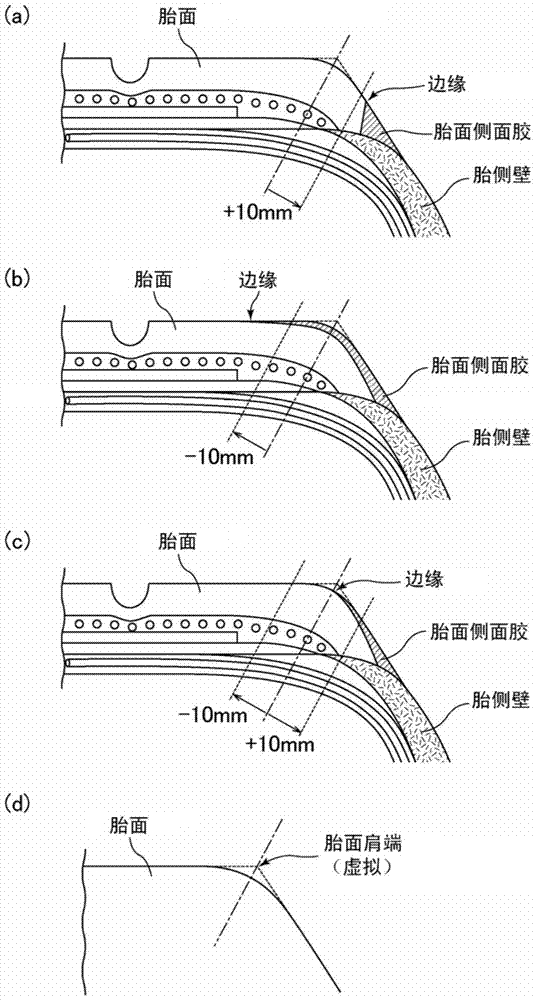

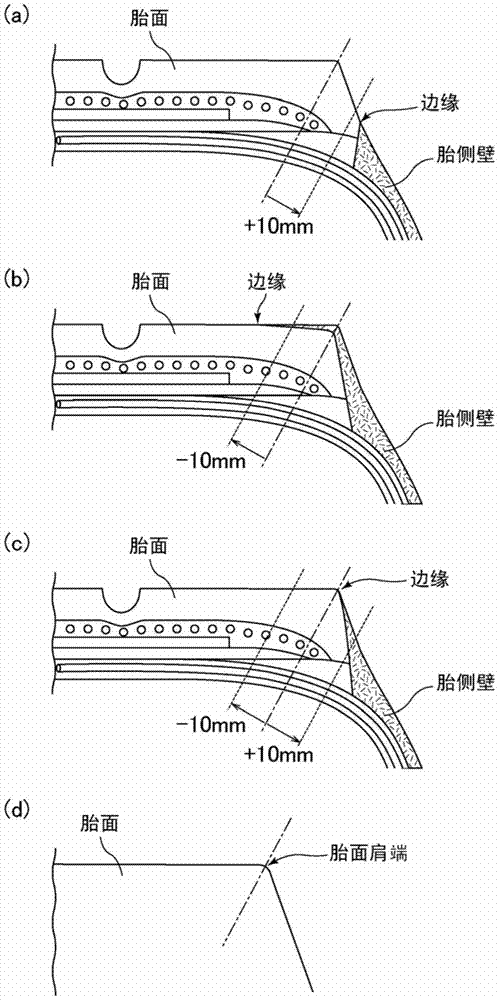

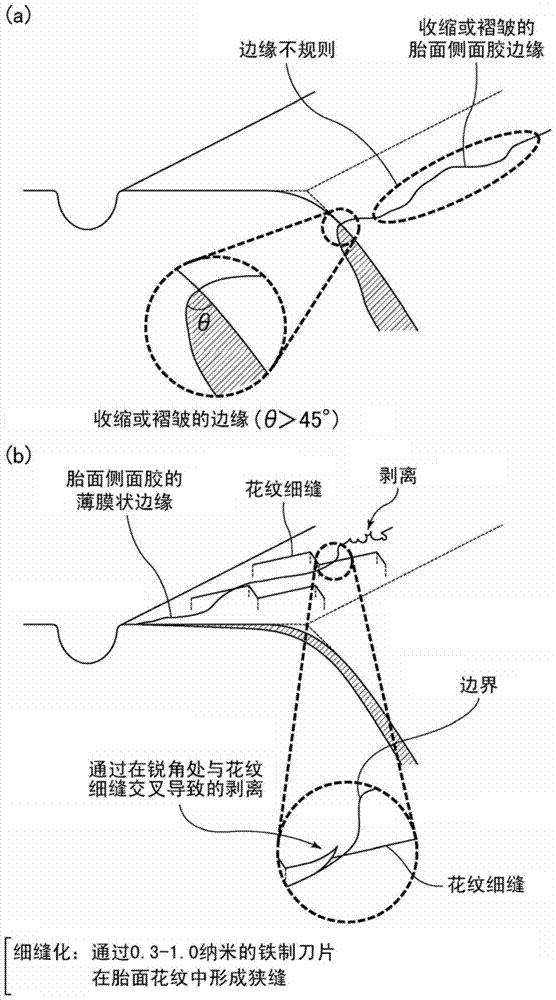

[0071] The present invention will be described more specifically with reference to examples of passenger car tires having a TOS structure, but the present invention is not limited to these examples.

[0072]

[0073] Add 23.6 g of 3-(N,N-dimethylamino)propyltriethoxysilane (manufactured by AZmax Corporation) to a vector bottle (100 ml) under a nitrogen protective atmosphere, and further add anhydrous hexane (Kanto Chemical company) to thereby prepare a total of 100 ml of terminal modifier.

[0074]

[0075] 18 liters of n-hexane (manufactured by Kanto Chemical Co., Ltd.), 2000 g of butadiene (manufactured by Takachiho Trading Co., Ltd.), and 2 mmol of tetramethylethylenediamine (manufactured by Kanto Chemical Company), and then increase the temperature to 60°C. Next, 10.3 ml of butyllithium (manufactured by Kanto Chemical Co., Ltd.) was added to the mixture, and then the temperature was increased to 50° C., followed by stirring for 3 hours. Then, 11.5 ml of the prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com