Embossed nonwoven fabric and production method thereof

A technology of non-woven fabrics and melt-blown non-woven fabrics, which is applied in the field of non-woven fabrics to achieve the effects of improving enterprise competitiveness, simple process, and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the scope of protection of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the patent scope of the present invention and the content of the description are still within the scope of the patent of the present invention.

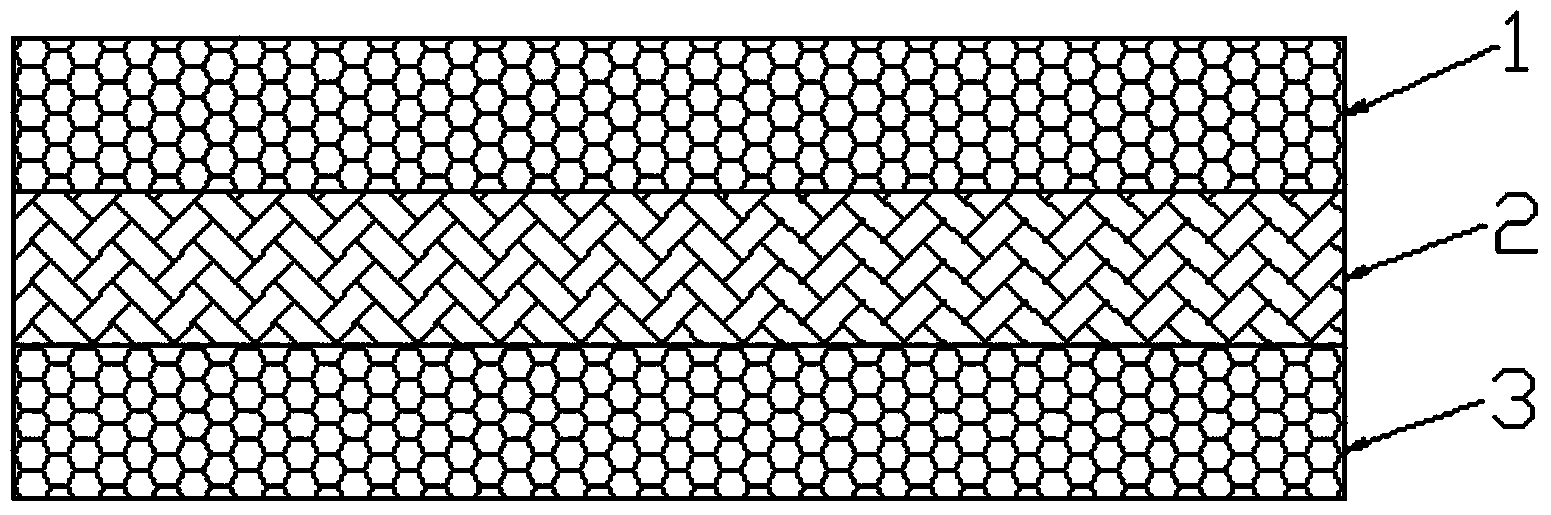

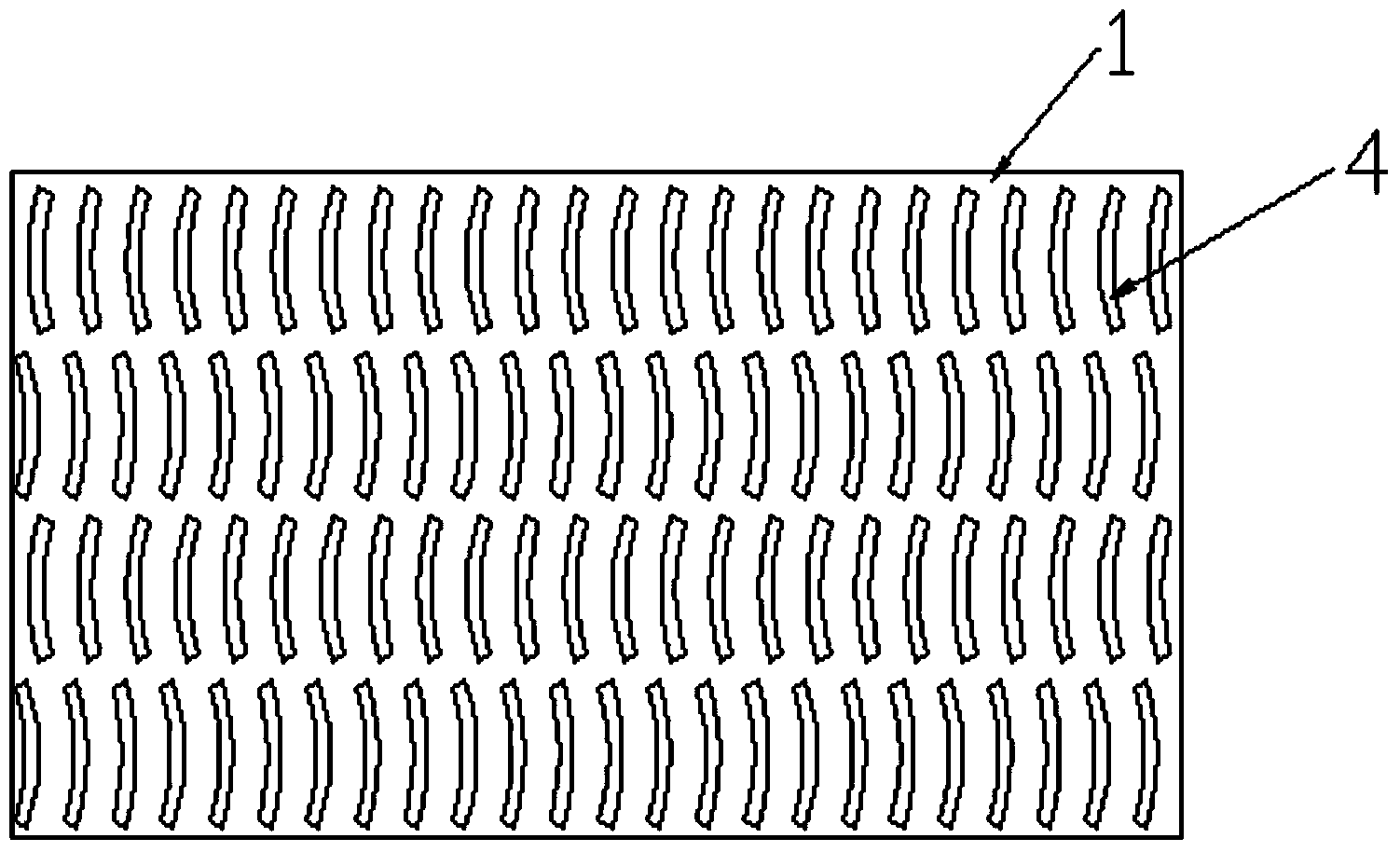

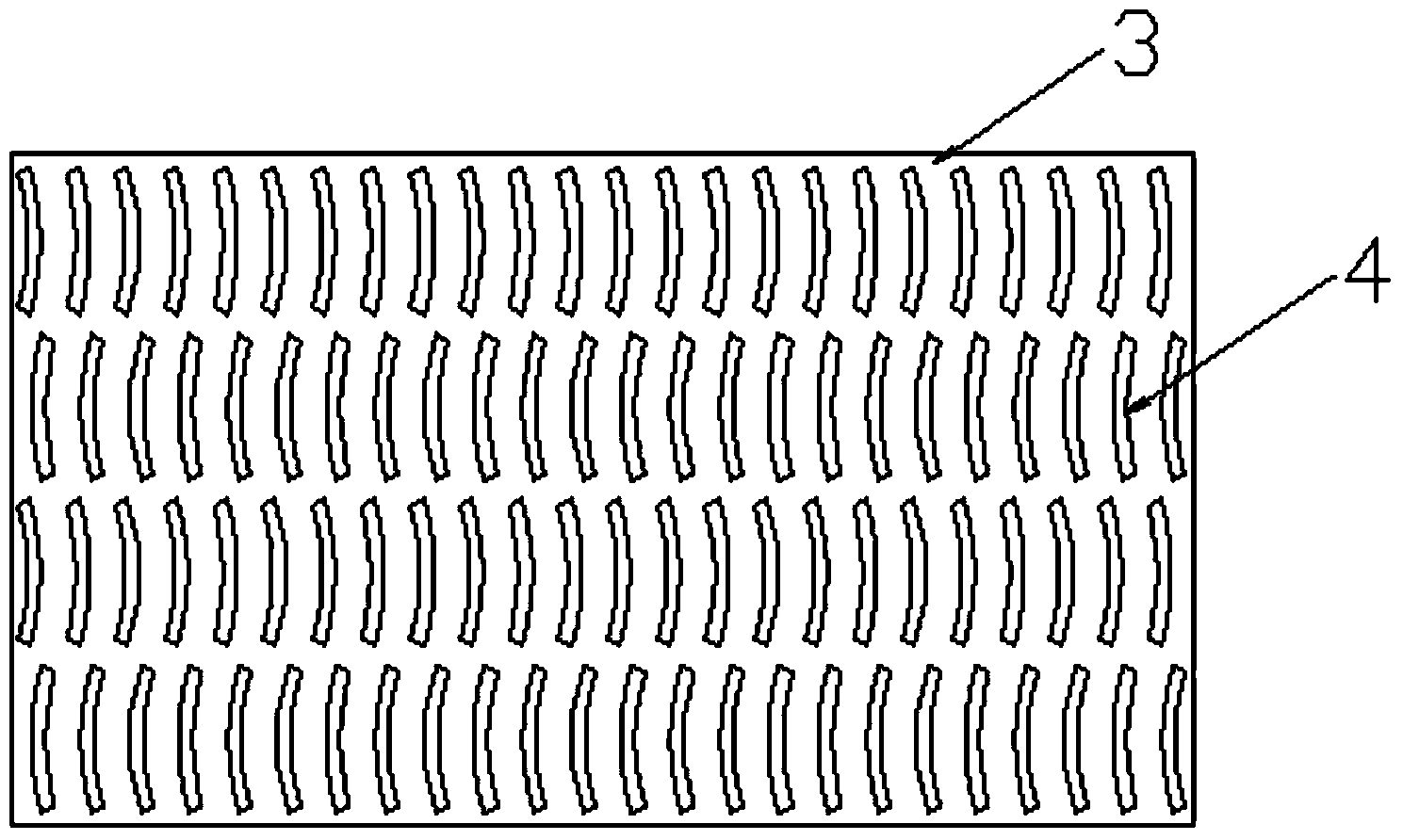

[0022] Such as Figure 1-3 As shown, an embossed nonwoven fabric is composed of an upper surface layer 1, an intermediate layer 2 and a lower surface layer 3 arranged in sequence, and is formed by pressing and compounding by pressing rollers. After pressing and combining by pressing rollers, the upper surface layer and the lower surface layer There are several rows of arc-moon-shaped embossings 4 arranged at intervals correspondingly formed on the surface, and two adjacent rows of arc-moon-shaped embossings are arranged in opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com