A high-yield, green synthesis method for conductive polyaniline

A conductive polyaniline, green synthesis technology, applied in the field of conductive polyaniline synthesis, can solve the problems of environmental protection, waste of resources, etc., and achieve the effects of saving resources, high utilization rate of waste liquid, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

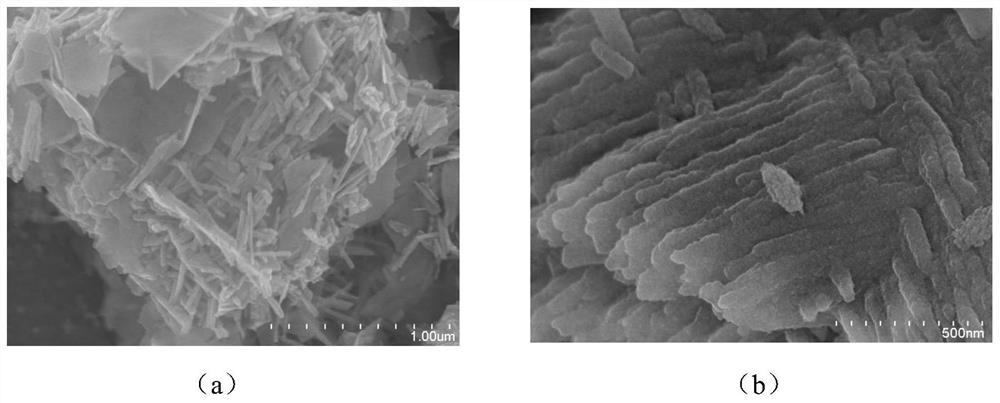

Embodiment 1

[0044] A high-yield, green synthesis method of conductive polyaniline, comprising the following steps:

[0045] (a) Dissolve the organic protonic acid in water and place it in a three-necked flask, add aniline monomer and oxidant at a stirring speed of 500rpm, the reaction temperature is 0°C, and the reaction time is 10h, wash and filter the obtained substance with water and ethanol , to obtain the 0th filtrate and No. 0 polyaniline powder, the organic protonic acid is toluenesulfonic acid, and the concentration of the organic protonic acid is 0.7mol / L;

[0046] (b) Take the 0th filtrate described in step (a) and place it in a three-necked flask, then add aniline monomer and oxidant at a stirring speed of 500rpm, the reaction temperature is 0°C, and the reaction time is 10h, and the obtained The substance was washed and filtered with water and ethanol to obtain the first filtrate and No. 1 polyaniline powder;

[0047] (c) Take the first filtrate described in step (b) and plac...

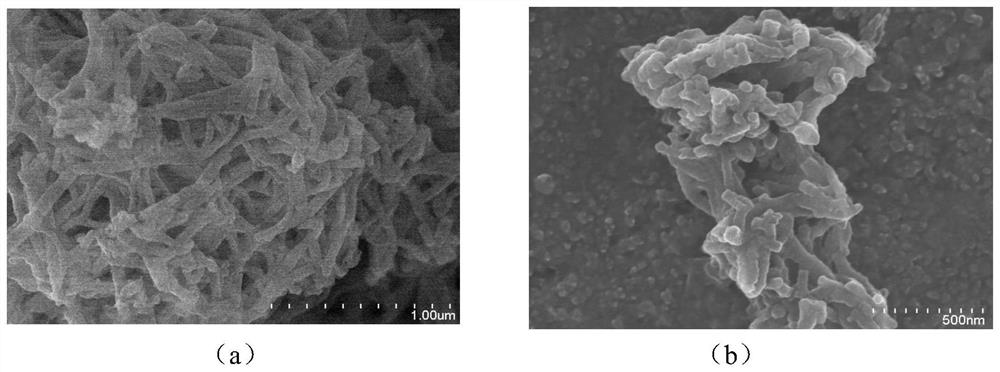

Embodiment 2

[0065] A high-yield, green synthesis method of conductive polyaniline, comprising the following steps:

[0066] (a) Dissolve the organic protonic acid in water and place it in a three-necked flask, add aniline monomer and oxidant at a stirring speed of 1000rpm, the reaction temperature is 30°C, and the reaction time is 5h, wash and filter the obtained substance with water and ethanol , to obtain the 0th filtrate and No. 0 polyaniline powder, the organic protonic acid is benzoic acid, and the concentration of the organic protonic acid is 0.7mol / L;

[0067] (b) Take the 0th filtrate described in step (a) and put it in a three-necked flask, add aniline monomer and oxidant at a stirring speed of 1000rpm, the reaction temperature is 30°C, and the reaction time is 5h, the obtained The substance was washed and filtered with water and ethanol to obtain the first filtrate and No. 1 polyaniline powder;

[0068] (c) Take the first filtrate described in step (b) and place it in a three-n...

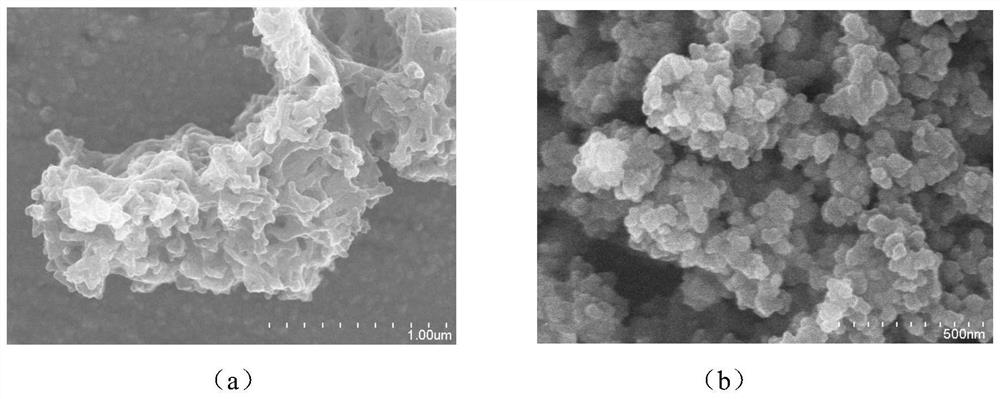

Embodiment 3

[0072] A high-yield, green synthesis method of conductive polyaniline, comprising the following steps:

[0073] (a) Dissolve the organic protic acid in water and place it in a three-necked flask, add aniline monomer and oxidant at a stirring speed of 500rpm, the reaction temperature is 30°C, and the reaction time is 10h, wash and filter the obtained substance with water and ethanol , to obtain the 0th filtrate and No. 0 polyaniline powder, the organic protonic acid is camphorsulfonic acid, and the concentration of the organic protonic acid is 0.7mol / L;

[0074] (b) Take the 0th filtrate described in step (a) and put it in a three-necked flask, add aniline monomer and oxidant at a stirring speed of 500rpm, the reaction temperature is 30°C, and the reaction time is 10h, the obtained The substance was washed and filtered with water and ethanol to obtain the first filtrate and No. 1 polyaniline powder;

[0075] (c) Take the first filtrate described in step (b) and place it in a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com