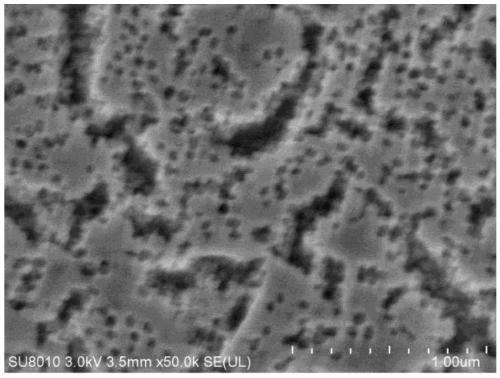

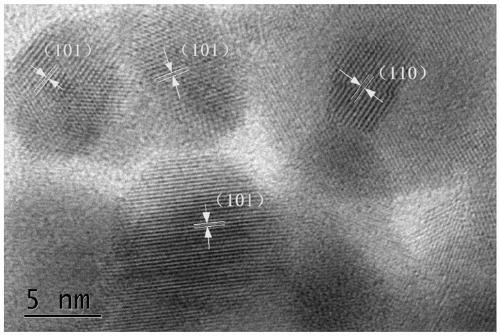

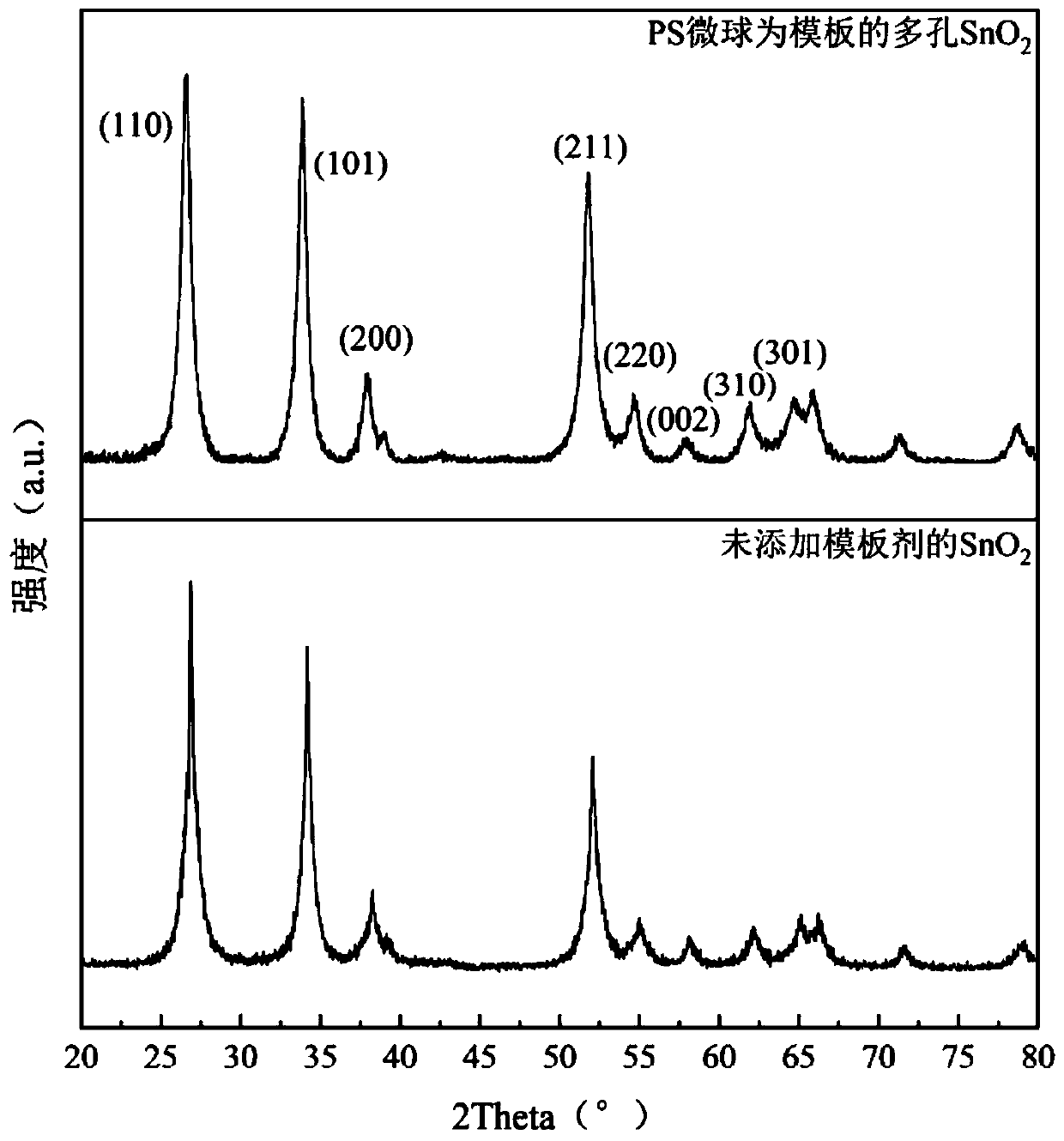

Porous SnO2 hydrogen-sensitive film and preparation and application thereof

A hydrogen-sensitive thin film and precursor liquid technology, applied in the field of sensors, can solve the problems of long response and recovery time, unsatisfactory stability, and poor sensitivity, and achieve the effect of regular arrangement, uniform size, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) 0.9g SnCl 4 2H 2 O was dissolved in 20ml of absolute ethanol, and then the prepared solution was stirred at 70°C at 600rpm for 1h, and the stirred solution was left to stand at 70°C for 24h to obtain a tin precursor;

[0047] (2) Take 0.4ml of PS microsphere monodispersion (PS microsphere content 2.5% w / v) and add it to 10ml of the tin precursor solution obtained in step (1), and stir at room temperature for 10-15min until a uniform PS tin precursor for suspension;

[0048] (3) Place the silicon substrate with the interdigitated platinum electrode successively in acetone, absolute ethanol and deionized water, respectively, and use ultrasonic cleaning for 4 to 5 minutes, and then place it in an oven at 100° C. for drying for later use;

[0049] (4) Spin-coat the tin precursor of the homogeneous PS suspension obtained in step (2) on the silicon substrate dried in step (3), and the amount of each layer of spin-coating solution is 25 μl / cm 2 , each layer of solution ...

Embodiment 2

[0061] (1) 0.9g SnCl 4 2H 2 O was dissolved in 20ml of absolute ethanol, and then the prepared solution was stirred at 65°C at 550rpm for 2h, and the stirred solution was left at 65°C for 24h to obtain a tin precursor;

[0062] (2) Take 0.2ml of PS microsphere monodispersion (PS microsphere content 2.5% w / v) and add it to 10ml of the tin precursor solution obtained in step (1), and stir at room temperature for 10-15min until a uniform PS tin precursor for suspension;

[0063] (3) Place the silicon substrate with the interdigitated platinum electrode successively in acetone, absolute ethanol and deionized water, respectively, and use ultrasonic cleaning for 4 to 5 minutes, and then place it in an oven at 100° C. for drying for later use;

[0064] (4) Spin-coat the tin precursor of the homogeneous PS suspension obtained in step (2) on the silicon substrate dried in step (3), and the amount of each layer of spin-coating solution is 25 μl / cm 2 , each layer of solution was first...

Embodiment 3

[0068] (1) 0.9g SnCl 4 2H 2 O was dissolved in 20ml of absolute ethanol, and then the prepared solution was stirred at 60°C at 500rpm for 3h, and the stirred solution was left to stand at 60°C for 24h to obtain a tin precursor;

[0069] (2) Take 1ml of PS microsphere monodispersion (PS microsphere content 2.5% w / v) and add it to 10ml of the tin precursor solution obtained in step (1), and stir at room temperature for 10-15min until a uniform PS suspension is obtained liquid tin precursor;

[0070] (3) Place the silicon substrate with the interdigitated platinum electrode successively in acetone, absolute ethanol and deionized water, respectively, and use ultrasonic cleaning for 4 to 5 minutes, and then place it in an oven at 100° C. for drying for later use;

[0071] (4) Spin-coat the tin precursor of the homogeneous PS suspension obtained in step (2) on the silicon substrate dried in step (3), and the amount of each layer of spin-coating solution is 25 μl / cm 2, each layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com