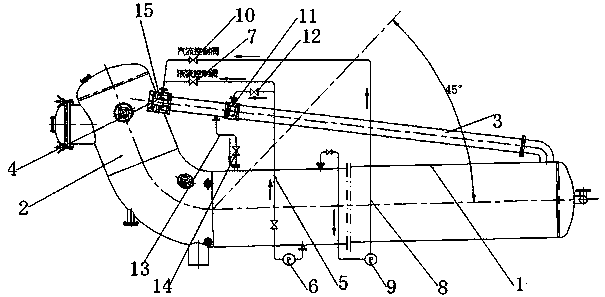

Up-walking steam and liquid flow rope-like dyeing machine

A rope-like dyeing machine and steam flow technology are applied in the directions of spray/jet textile material processing, textile material processing equipment configuration, etc., to achieve the effect of good dyeing effect, benefiting the environment and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The installation position of the main cylinder is upturned at the tail end, and the tail end of the main cylinder is at an angle of 0-45° to the front end of the main cylinder. When the cloth enters the nozzle of the cloth guide pipe, the spray dyeing is carried out by the mist steam carrying the dyeing liquid and the cloth is pushed into the cloth guide pipe. After assisting the dyeing and circulation boosting of the cloth, the cloth enters the main cylinder. At this time, the main cylinder with the upturned end is smoothly circulated in the dyeing machine due to the gravity and the action of the dye solution.

[0018] There is an automatic air bag removal device in front of the steam jet nozzle. Our company has applied for a utility model patent (application acceptance number 201320043945.2) - an automatic air bag removal device, which removes and partially removes the air bag and dyeing liquid carried in the cloth dyeing cycle. It is conducive to the deeper penetrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com