A well layout method for surface pumping and drainage of coalbed methane

A technology of coalbed methane and coalbed, which is applied in the field of well layout for ground pumping and drainage of coalbed methane, to achieve the effect of increasing drainage and pressure reduction efficiency and improving development effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

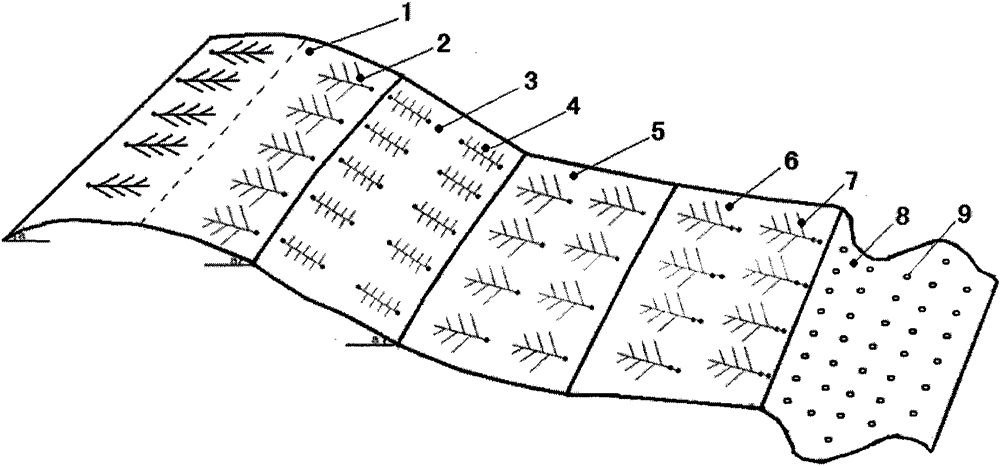

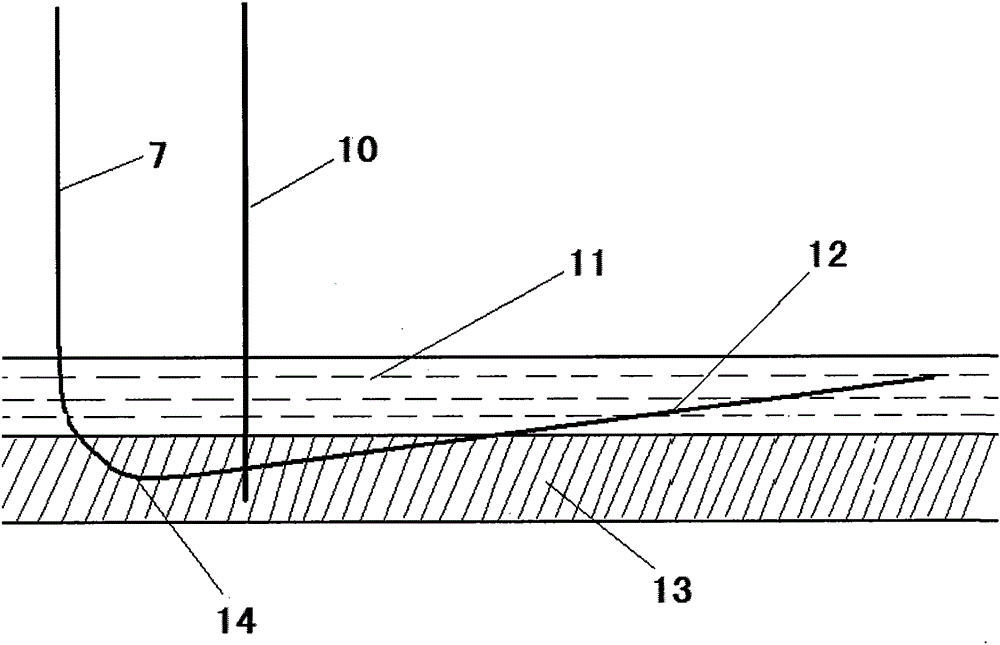

[0015] The present invention will be further described below in conjunction with specific embodiments. figure 1 It can be used as a schematic diagram of well layout for ground pumping and drainage of coalbed methane according to the structural form of the coal seam in this embodiment. figure 2 It can be used as a schematic diagram of a multi-branch horizontal well applicable to horizontal formations or gentle formations with a coal seam dip angle less than 2° in this embodiment.

[0016] According to the analysis of seismic data and drilled data, the structural form of a certain coalbed methane development block is as follows: figure 1 As shown, (1) is the turning point of the fold structure with the stratum dip angle between 2-8°, (3) is the monoclinic coal seam with the stratum dip angle greater than 8°, (5) is the stratum dip angle between 2-8° (6) is a monocline coal seam with a stratum dip angle less than 2°, and (8) is an area with large fluctuations and irregularities...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com