Jet ejector for automatic dilution of upper corner gas

An ejector and corner technology, applied in the field of new jet ejectors, can solve problems such as threats to mine safety production, wind turbulence, and easy accumulation of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and examples of implementation.

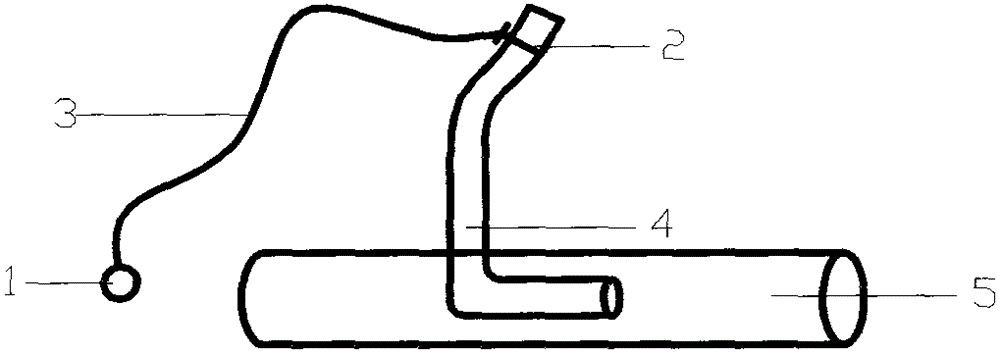

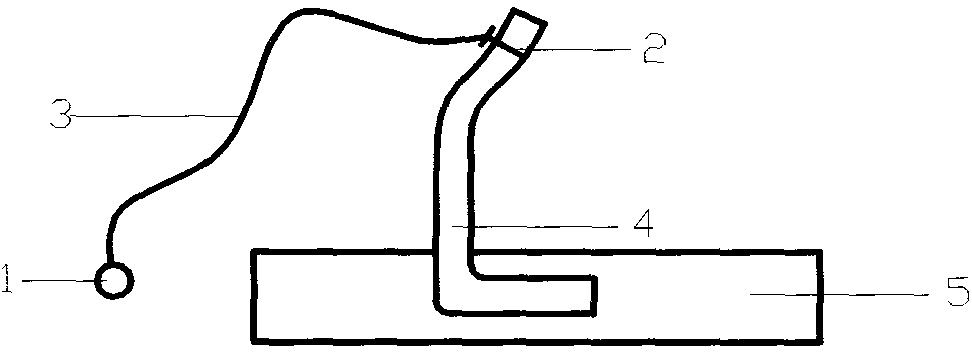

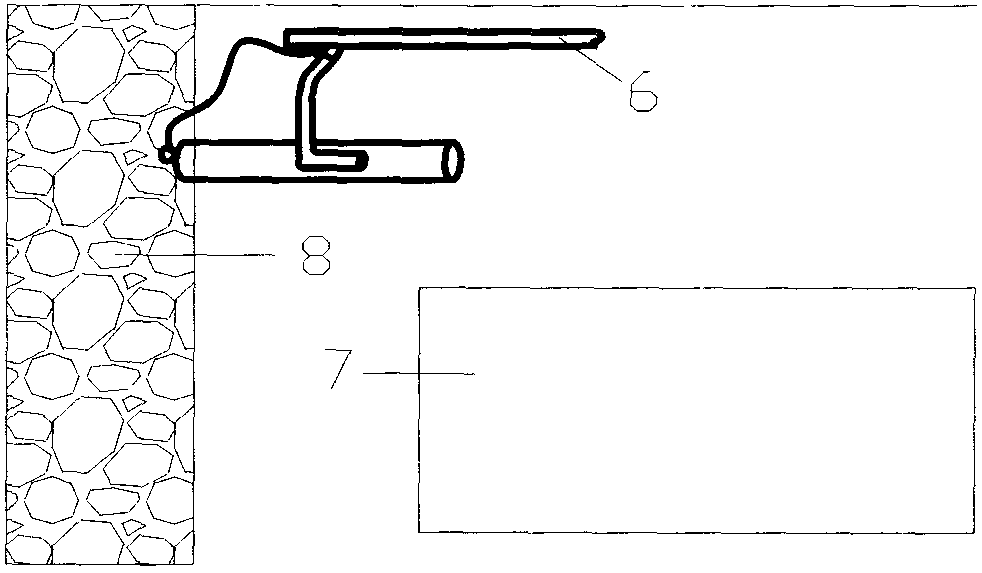

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, the present invention comprises that the present invention comprises sensor (1), and sensor (1) and sensor switch (2) are connected by signal wire (3), and air inlet pipe (4) stretches in the injection pipe, and air inlet pipe (4) ) is connected to the downhole pressure air pipe (6) through the sensor switch (2).

[0015] Connect the jet ejector to the air pressure pipe at the upper corner of the mining face (7), extend the sensor and the jet ejector into the goaf (8), when the sensor (1) detects the gas in the upper corner When the limit is exceeded, the sensor switch (2) is turned on, and the air is supplied to the jet ejector through the pressure air pipe. When the air is supplied, the pressure in the jet ejector decreases, so the gas can be sucked into the jet sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com