Rotor wheel disc

A technology of rotor wheels and discs, which is applied to the supporting elements of blades, components of pumping devices for elastic fluids, non-variable pumps, etc., and can solve problems affecting the efficiency of steam turbines and gas turbines, blade wear, etc. Achieve the effects of preventing blade tilting, improving service life, and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

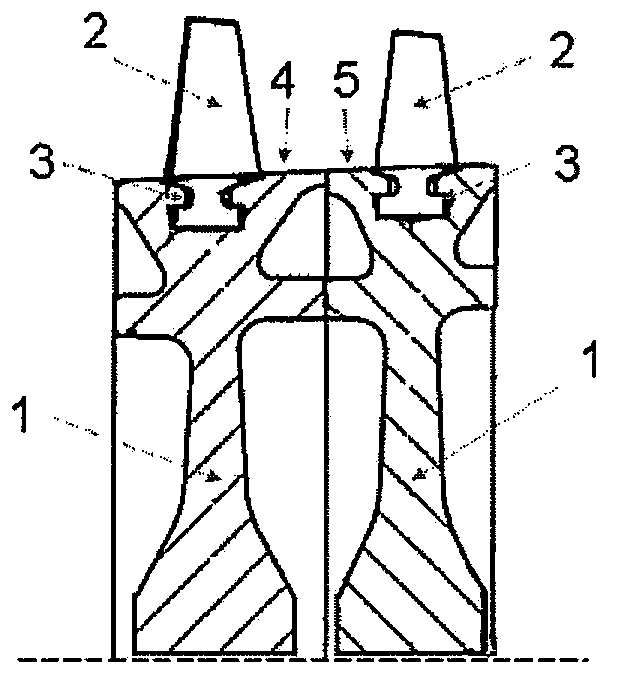

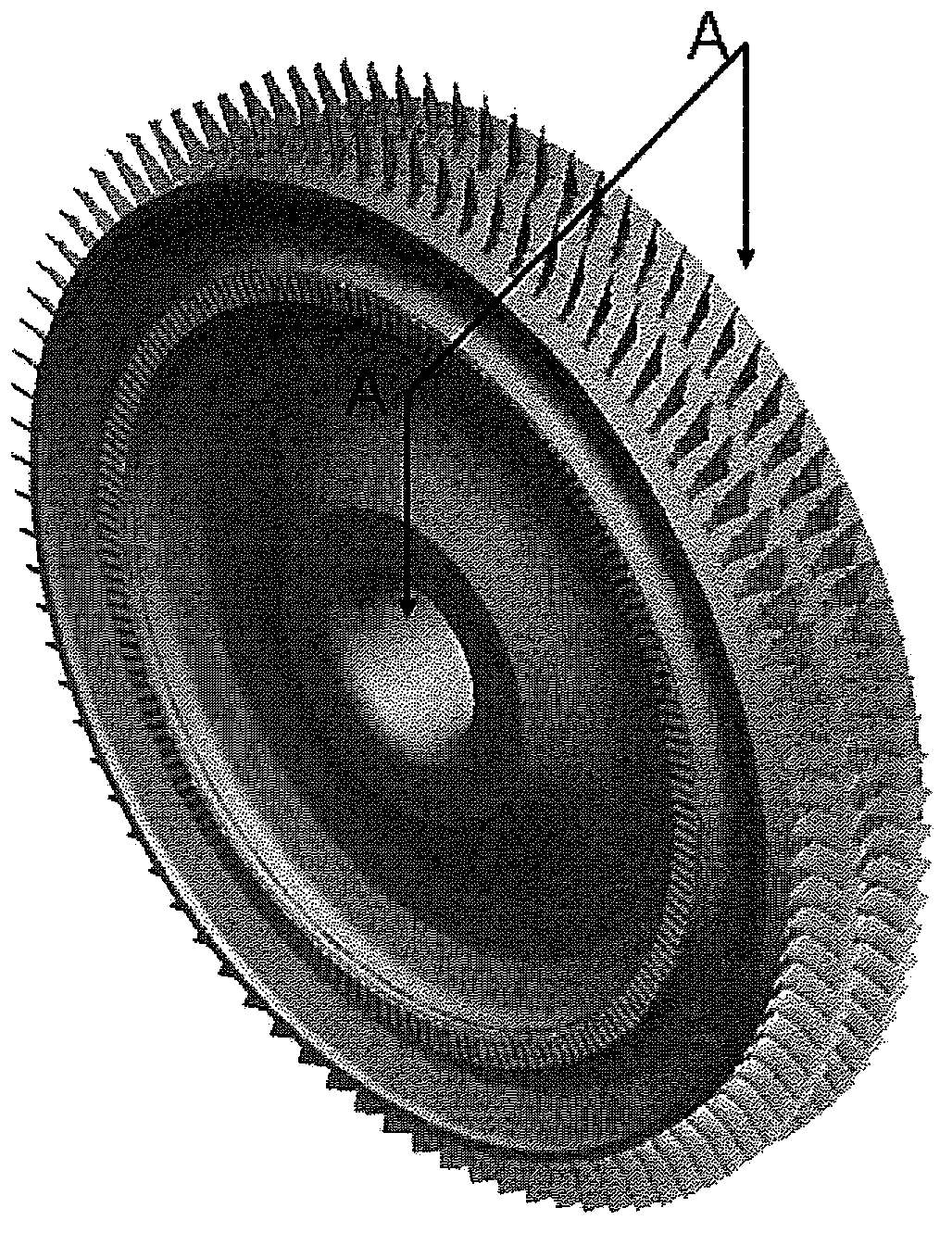

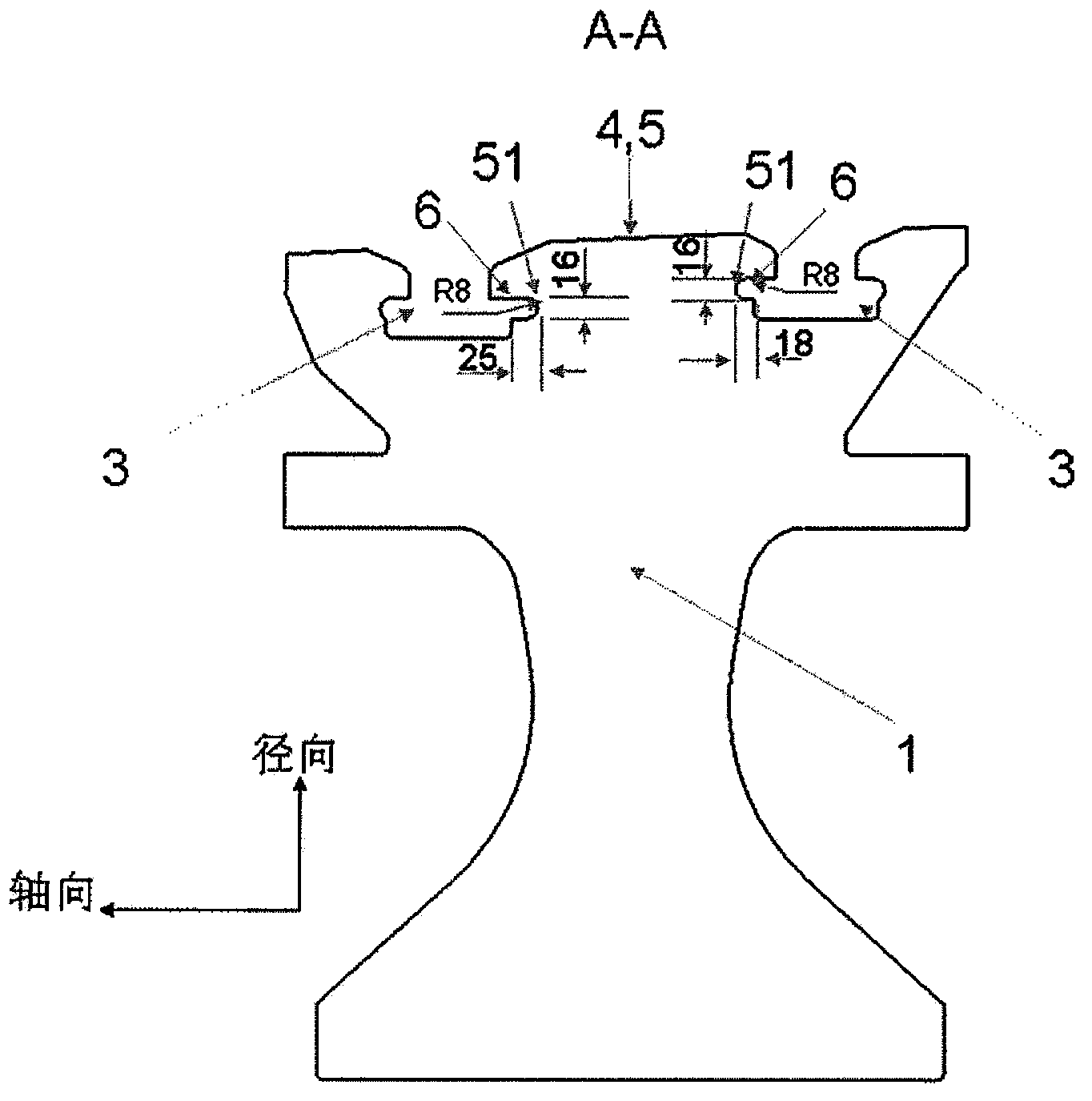

[0017] The reference numerals for the various components in the figures are as follows: rotor disk 1 , blades 2 , root groove 3 , rotor disk parts 4 and 5 , recess 6 , recess chamfer 51 .

[0018] like figure 2 and 3 As shown, the blades 2 are fixed to the rotor disk 1 by means of the blade root slots 3 . The blade root groove is a T-shaped groove formed by rotary cutting along the circumferential direction of the rotor disk. The blade root groove 3 is provided with a concave portion 6 on the side of the rotor disk with greater rigidity, and the concave portion 6 can penetrate the blade root groove 3 in the circumferential direction of the rotor disk. The concave portion 6 can be machined by cutting with a tool, the tool machining is easy to operate, and the machining cost is low. The concave portion 6 penetrates the blade root groove 3 so that the concave portion and the blade root groove can be processed at the same time, and the inclination of all the blades can be impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com